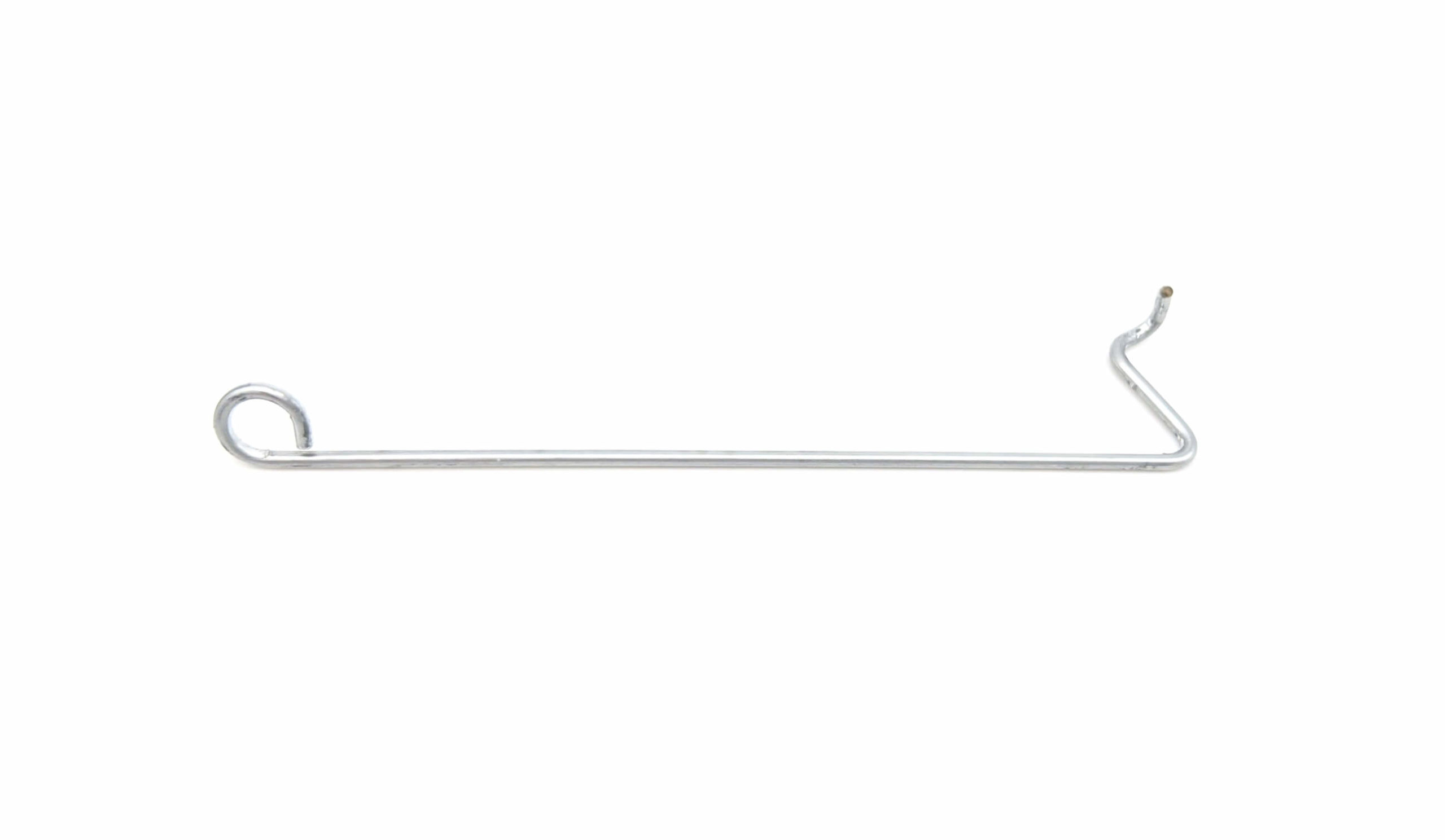

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of mechanics, springs are the silent heroes, providing resilience, storing energy, and enabling countless functionalities. Among these remarkable devices, torsion springs stand out as marvels of engineering,

In the realm of mechanics, springs are the silent heroes, providing resilience, storing energy, and enabling countless functionalities. Among these remarkable devices, torsion springs stand out as marvels of engineering, capable of twisting and storing energy in a rotational motion. From the delicate balance of a watch's hairspring to the robust suspension of a vehicle, torsion springs play a vital role in our daily lives, often unnoticed but undeniably essential.

Unlike their linear counterparts, tension and compression springs, torsion springs excel in the world of rotational forces. These springs, when subjected to a twisting force, store energy in a manner similar to their counterparts. The key difference lies in their geometry and the way they respond to applied forces. Instead of stretching or compressing, torsion springs are designed to twist, effectively converting rotational force into stored energy.

A torsion spring typically consists of a length of wire, often made of spring steel, coiled into a helix. The ends of the spring are fixed to a rigid structure, and a twisting force is applied to one of the ends. This force causes the spring to wind up, storing energy in the process. As the force is released, the spring unwinds, releasing the stored energy back into the system.

The unique ability of torsion springs to store and release rotational energy has led to their widespread adoption across various industries. These versatile springs find applications in countless mechanical systems, ranging from the miniature to the grand, making a significant impact on our everyday lives.

Imagine a delicate, intricate mechanism like a watch, where every tick and tock is measured with precision. Torsion springs, often referred to as hairsprings in this context, play a crucial role in regulating the movement of a watch's hands. They are responsible for providing a constant, controlled force that ensures accurate timekeeping. These minuscule springs are marvels of engineering, demonstrating the power of torsion springs to deliver precise control even on the smallest of scales.

On the other end of the spectrum, torsion springs are used in vehicle suspensions, ensuring a smooth ride and providing a safe and comfortable experience for passengers. These springs, often found in torsion bar suspensions, are designed to withstand significant forces and absorb shocks from uneven surfaces. Their robust construction and ability to store and release large amounts of energy make them ideal for this demanding application.

The applications of torsion springs extend far beyond watches and vehicles. They find their way into a wide array of mechanical systems, playing a critical role in the functionality of doors, gates, springs, and countless other devices. In door hinges, torsion springs ensure smooth, effortless operation, while in garage door openers, they provide the necessary power to lift heavy doors with ease.

To design and utilize torsion springs effectively, it's essential to understand their key characteristics. The most crucial parameter is the spring rate, which dictates the relationship between the applied torque and the resulting angular deflection. Higher spring rates correspond to stiffer springs that require more force to twist, while lower rates indicate more compliant springs that deform easily under load.

Designing torsion springs involves a careful consideration of various factors, including the desired spring rate, the required operating force, and the size and geometry of the spring. Engineers often use specialized software tools to simulate and optimize the design of torsion springs, ensuring they meet specific performance requirements.

The choice of material is critical for the performance and longevity of torsion springs. Spring steel is a popular choice, offering excellent strength, resilience, and fatigue resistance. Other materials, such as phosphor bronze and beryllium copper, may be selected for specific applications that demand corrosion resistance or high conductivity.

As technology continues to evolve, so too do the applications and capabilities of torsion springs. Advancements in materials science, manufacturing processes, and design techniques are leading to the development of more sophisticated torsion springs with enhanced performance, durability, and functionality. From micro-sized torsion springs used in medical devices to large-scale springs used in renewable energy systems, the future of torsion springs holds exciting possibilities.

Torsion springs, with their ability to store and release rotational energy, play a vital role in the intricate workings of our world. From the delicate balance of a watch to the robust suspension of a vehicle, torsion springs are marvels of engineering, enabling countless functionalities and contributing to the seamless operation of countless devices. As technology advances, torsion springs continue to evolve, expanding their applications and contributing to innovation across various industries.

In conclusion, torsion springs are essential components in various mechanical systems, offering unique properties and enabling precise control over rotational motion. Understanding their characteristics and applications empowers us to harness their potential and design innovative solutions across numerous fields. As technology progresses, we can expect to witness even more sophisticated and versatile torsion springs, further enhancing the possibilities of modern engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.