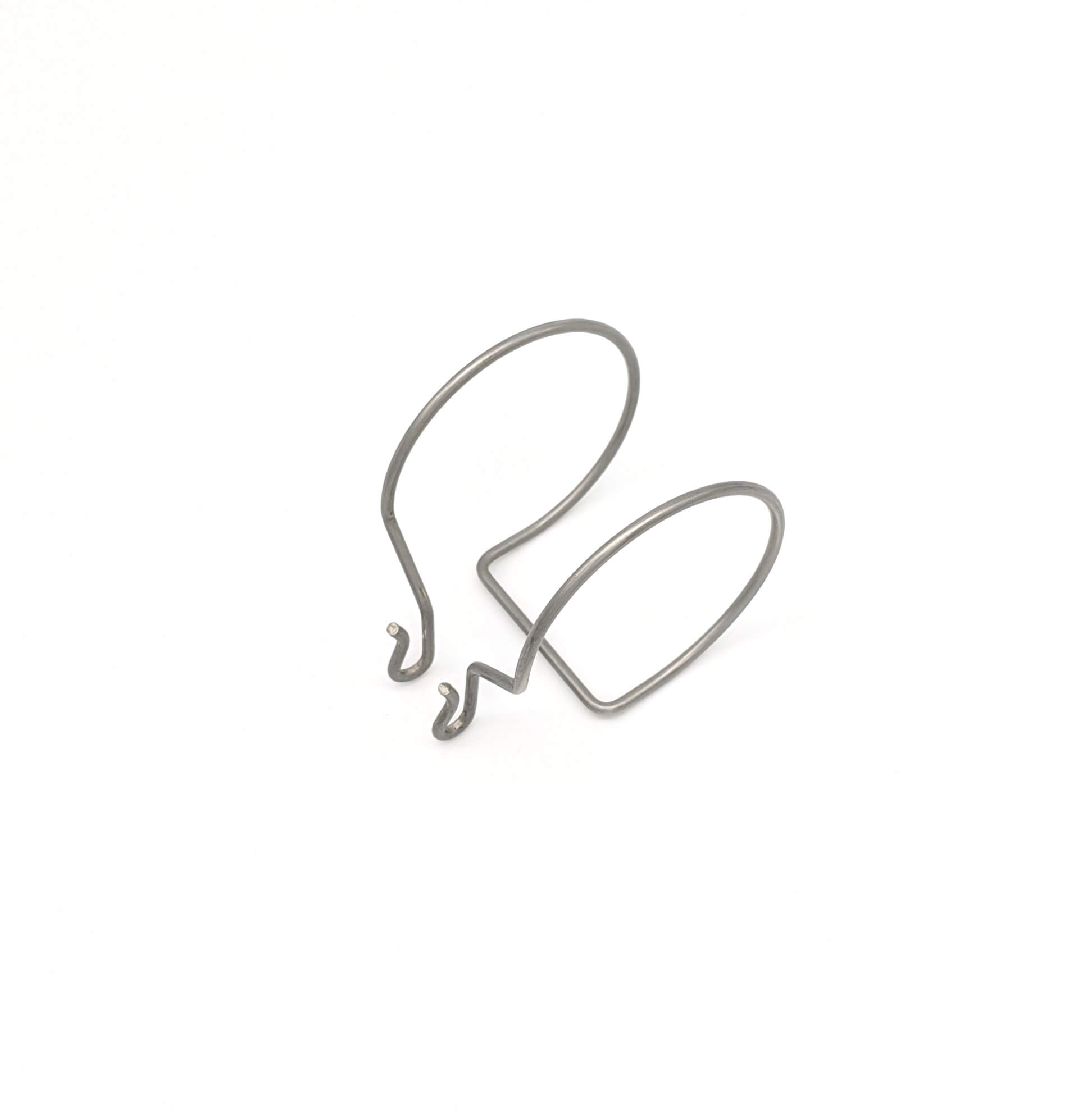

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil springs, ubiquitous in countless applications from car suspensions to door hinges, hold the potential to deliver exceptional performance. But within their seemingly simple design lies a critical element –

Coil springs, ubiquitous in countless applications from car suspensions to door hinges, hold the potential to deliver exceptional performance. But within their seemingly simple design lies a critical element – the spacing between their coils. This seemingly minor detail significantly impacts the spring's characteristics, dictating its stiffness, load capacity, and overall function. Understanding the nuances of coil spring spacing, particularly the concept of twist, unlocks a deeper appreciation for the intricate world of spring design and its impact on real-world applications.

Imagine a coil spring, its wire meticulously wound around a central axis. The spacing between these coils isn't just a random arrangement; it's a carefully engineered design that dictates the spring's behavior. One crucial aspect of this spacing is the "twist" – the subtle, yet significant, rotation between adjacent coils. This twist isn't just a decorative element; it plays a pivotal role in the spring's performance.

Think of a tightly wound coil spring. When compressed, the coils move closer together, storing energy within their elastic material. The twist in the spacing determines how efficiently this energy is stored and released. A spring with a higher twist will have a steeper force-deflection curve, meaning it requires more force to compress it but releases that energy with greater force. This relationship between twist and spring behavior is key to understanding its function.

The twist in coil spring spacings has a profound impact on a spring's fundamental characteristics. Here's how:

The ideal twist for a coil spring isn't a one-size-fits-all solution. It's a critical design parameter that engineers meticulously choose based on the intended application. Here are some examples:

The twist in coil spring spacings might seem like a subtle detail, but its impact on a spring's performance is undeniable. Understanding this concept opens a window into the fascinating world of spring design and its vital role in countless applications. Engineers, designers, and manufacturers constantly refine their understanding of twist to create springs that are not only strong and reliable but also perfectly tailored to the specific needs of each application.

In the intricate world of coil spring design, twist in spacing emerges as a pivotal factor. It's not just a cosmetic feature; it's a key to unlocking a spring's full potential. Whether it's in the smooth ride of a car, the precise movements of a clock, or the critical functions of a medical device, understanding the nuances of twist allows us to appreciate the elegant interplay between design and performance in the seemingly simple world of springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.