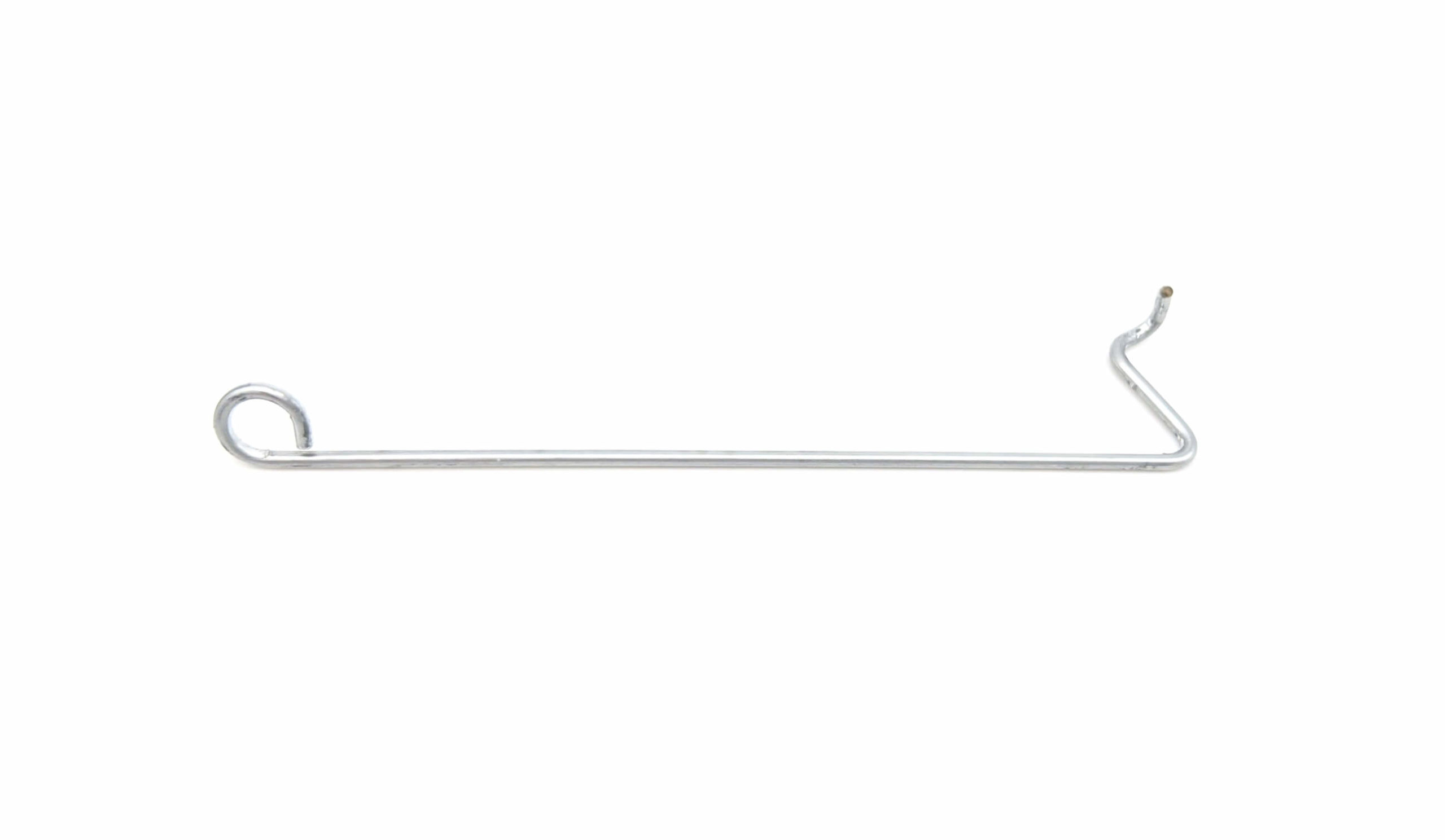

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered about the simple yet powerful act of compressing a coil spring? It's a seemingly mundane action, but it holds a fascinating world of physics, engineering, and

Have you ever wondered about the simple yet powerful act of compressing a coil spring? It's a seemingly mundane action, but it holds a fascinating world of physics, engineering, and everyday applications. From the delicate springs in your watch to the robust ones in your car's suspension, these coiled marvels are essential components in countless devices. In this exploration, we'll delve into the science behind compressing a coil spring, unraveling the forces at play and understanding how these seemingly simple mechanisms power our world.

At its core, compressing a coil spring involves applying a force that causes the spring to shorten in length. This compression is governed by a fundamental principle known as Hooke's Law. Formulated by the brilliant Robert Hooke in the 17th century, this law states that the force exerted by a spring is directly proportional to its extension or compression. In simpler terms, the more you compress a spring, the greater the force it pushes back with.

To visualize this, imagine a coil spring like a tiny, coiled-up Slinky. When you push down on it, it resists and pushes back. The harder you push, the stronger the spring's resistance becomes. This resistance is measured by the spring constant, denoted by 'k', which represents the stiffness of the spring. A higher spring constant signifies a stiffer spring, requiring more force to compress it.

The act of compressing a spring involves storing energy within its coils. This stored energy is known as elastic potential energy, which represents the potential of the spring to return to its original shape. As you compress the spring, you're essentially storing this energy within its structure. When you release the spring, this stored energy is transformed back into kinetic energy, causing the spring to expand and potentially perform work.

The amount of energy stored in a compressed spring can be calculated using a simple formula:

Potential Energy = (1/2) * k * x^2

Where 'k' is the spring constant and 'x' is the compression distance.

The humble coil spring, with its ability to store and release energy, has found its way into countless applications, making it a ubiquitous component in modern technology. Here are just a few examples:

Coil springs are the backbone of modern vehicle suspensions. They absorb the shock of bumps and potholes, ensuring a comfortable ride. When you drive over a bump, the spring compresses, absorbing the impact energy. As you drive on, the spring expands, returning the vehicle to its original height. This continuous compression and expansion process is what keeps your car stable and comfortable.

From grandfather clocks to wristwatches, the ticking heart of every mechanical timepiece is powered by a mainspring. This spring, carefully wound, stores energy that is slowly released, driving the clock's gears and hands. The constant compression and decompression of the mainspring ensures the consistent movement of the clock's mechanism.

Those spring-loaded door closers you find on many doors aren't just for aesthetics. They utilize compression springs to provide a controlled closing force. As you open a door, the spring extends. When you release the door, the spring compresses, gently guiding the door closed, preventing slamming and ensuring safety.

Look around your home, and you'll find springs in many appliances. From the spring-loaded levers in your refrigerator door to the tension springs in your washing machine, these seemingly simple components play vital roles in their operation. They provide the force needed for various functions, from opening and closing doors to controlling the movement of parts.

In the medical field, compression springs are essential for a variety of devices. They power the movement of medical syringes, ensuring precise and controlled medication delivery. They are also found in surgical instruments, assisting with delicate procedures. In prosthetics, springs provide the necessary force for movement and articulation.

While we've focused on the standard compression spring, there's a whole world of spring variations out there, each designed for specific applications and purposes. Some examples include:

These springs have a changing stiffness, which means their resistance to compression varies depending on the amount of force applied. This allows for more tailored performance in applications where the load on the spring changes.

Unlike compression springs that are compressed along their axis, torsion springs are designed to resist twisting forces. They are often used in applications like garage door openers, where a twisting motion is needed.

These springs are designed to extend in length when a force is applied, rather than compress. They're commonly found in applications like door hinges, retractable cords, and some types of suspension systems.

These disc-shaped springs are used to apply a constant force to bolts or other fasteners. They are commonly used in applications where a consistent clamping force is required, such as in machinery and automotive parts.

From the everyday conveniences of a door closer to the intricate mechanisms of a watch, compressing a coil spring may seem simple, but it's a fundamental act that underpins a vast array of applications. By understanding the science behind compression and the versatility of spring designs, we gain a deeper appreciation for these seemingly simple yet powerful components that shape our world.

So the next time you encounter a spring, whether in a car, a watch, or a simple door, remember the fascinating world of physics and engineering that lies behind its seemingly straightforward compression. These springs, with their ability to store and release energy, are truly a marvel of ingenuity, silently powering our world in countless ways.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.