Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spira wav springs, also known as wave springs, are a fascinating and highly efficient type of spring that offers numerous advantages over conventional coil springs. These springs are designed with

Spira wav springs, also known as wave springs, are a fascinating and highly efficient type of spring that offers numerous advantages over conventional coil springs. These springs are designed with a unique wave-like configuration, which provides exceptional durability, increased load-carrying capacity, and a remarkable ability to withstand extreme conditions. If you're seeking a spring solution that delivers superior performance and longevity, Spira wav springs are an excellent choice for a wide range of applications. This comprehensive guide will delve into the intricacies of Spira wav springs, exploring their construction, benefits, applications, and considerations for selection.

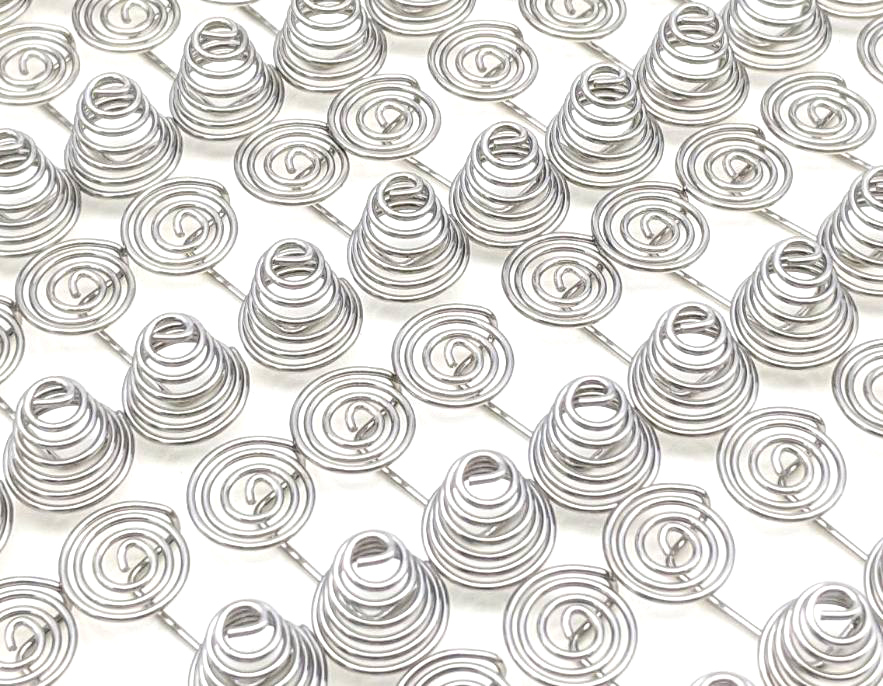

Spira wav springs, often referred to as wave springs, are a distinctive type of spring characterized by their unique wave-like configuration. Unlike traditional coil springs, which are wound in a continuous helix, Spira wav springs are formed by stacking a series of individual wave-shaped elements. These elements are precision-engineered to interlock and create a compact, yet highly resilient spring assembly. The wave-like design allows for a remarkable combination of high load capacity, reduced space requirements, and enhanced durability.

The manufacturing process of Spira wav springs is equally intriguing. They are typically produced using high-quality materials like spring steel, which is carefully shaped and formed to create the wave elements. The individual waves are then precisely stacked and assembled, creating a cohesive spring with exceptional performance characteristics.

Spira wav springs offer a compelling range of benefits that make them a superior choice for various applications. Let's delve into some of the key advantages:

**1. High Load Capacity:** One of the most notable benefits of Spira wav springs is their remarkable load-carrying capacity. The wave-like configuration allows them to handle significantly higher loads compared to traditional coil springs of the same size. This makes them ideal for applications where space is limited, but high load-bearing capabilities are crucial.

**2. Compact Design:** Spira wav springs are incredibly compact, occupying significantly less space than conventional coil springs. This feature is particularly valuable in applications where space is a premium, such as in tight machinery or confined environments. The smaller footprint of Spira wav springs can lead to improved design flexibility and reduced overall system size.

**3. Excellent Fatigue Resistance:** The unique wave design of Spira wav springs contributes to their exceptional fatigue resistance. They can withstand repeated compression and extension cycles without exhibiting significant wear or degradation. This characteristic makes them highly reliable for applications requiring long service life and high cyclic loading.

**4. Shock Absorption:** The wave-like configuration of Spira wav springs provides excellent shock absorption capabilities. They can effectively dampen vibrations and impacts, reducing stress on the surrounding components and improving overall system stability.

**5. Reduced Friction:** Spira wav springs exhibit lower friction compared to conventional coil springs due to the reduced contact surface between the waves. This minimized friction contributes to smooth and efficient spring operation, reducing wear and tear over time.

**6. Temperature Stability:** Spira wav springs are designed to maintain their performance characteristics over a wide range of temperatures. This is particularly important in applications involving extreme environments where temperature variations can affect the behavior of traditional springs.

The versatility of Spira wav springs has led to their widespread adoption in a diverse range of applications across numerous industries. Some common applications include:

**1. Automotive Industry:** Spira wav springs play a vital role in the automotive industry, serving as valve springs, clutch springs, and suspension components. Their high load capacity, compact size, and durability make them ideal for meeting the demands of modern vehicles.

**2. Aerospace Industry:** The aerospace industry demands high-performance components, and Spira wav springs excel in meeting these requirements. They are used in landing gear, actuators, and other critical systems where reliability and strength are paramount.

**3. Industrial Machinery:** Spira wav springs are essential components in industrial machinery, contributing to the smooth and efficient operation of various equipment. They are used in presses, stamping machines, and other heavy-duty machinery where high forces and repeated cycles are involved.

**4. Medical Devices:** Spira wav springs find applications in medical devices, including surgical instruments, prosthetic limbs, and medical implants. Their biocompatibility and bio-inert nature make them suitable for use in the human body.

**5. Consumer Electronics:** The compact size and high reliability of Spira wav springs make them suitable for use in consumer electronics. They are found in smartphones, laptops, and other devices where space is limited and performance is critical.

Selecting the appropriate Spira wav spring for a specific application requires careful consideration of several factors, including:

**1. Load Capacity:** Determine the maximum load that the spring will be subjected to. Spira wav springs are available in a wide range of load capacities to meet the specific requirements of your application.

**2. Deflection:** The deflection of the spring is the amount it will compress or extend under a given load. Select a spring with a deflection that meets the needs of your application.

**3. Spring Rate:** The spring rate is a measure of the stiffness of the spring. It indicates the amount of force required to compress or extend the spring by a specific distance.

**4. Material:** The material of the Spira wav spring is critical to its performance. Spring steel is a common choice, but other materials such as stainless steel or phosphor bronze may be suitable for specific applications.

**5. Environment:** Consider the environment in which the spring will be operating. Factors such as temperature, humidity, and corrosive substances can affect the performance of the spring.

Spira wav springs offer a compelling combination of high load capacity, compact design, and exceptional durability, making them a superior choice for a wide range of applications. From automotive and aerospace to industrial machinery and medical devices, these springs deliver reliable performance in demanding environments. By understanding the benefits, applications, and selection criteria of Spira wav springs, engineers and designers can leverage their unique capabilities to create innovative and efficient solutions.

As you embark on your spring design journey, remember that Spira wav springs are a powerful tool for overcoming space constraints, achieving high load capacities, and ensuring long-lasting performance. Embrace the versatility and efficiency of these remarkable springs, and unlock a new level of innovation in your projects.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.