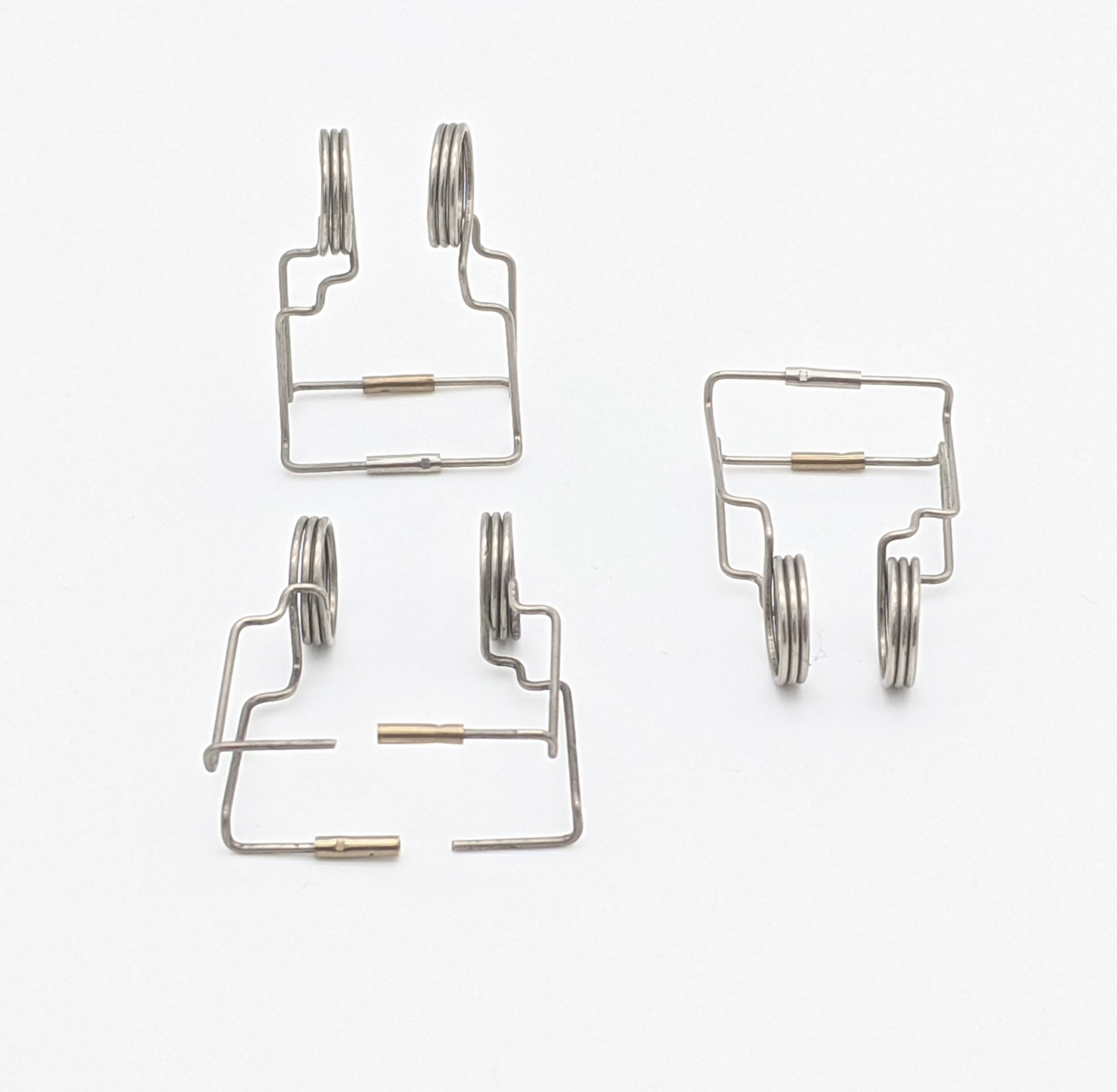

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs are indispensable components, offering the ability to store and release energy. Among the diverse types of springs, constant springs stand out for their

In the world of mechanical engineering, springs are indispensable components, offering the ability to store and release energy. Among the diverse types of springs, constant springs stand out for their unique characteristic: they maintain a consistent force throughout their deflection cycle. This seemingly simple feature has profound implications for various applications, from delicate instruments to heavy-duty machinery. This article dives deep into the realm of constant springs, exploring their workings, advantages, and common applications, revealing why these unassuming components play a pivotal role in our modern world.

Imagine a spring that, no matter how much you compress or extend it, always exerts the same force. This is the essence of a constant spring, a marvel of engineering that offers unparalleled consistency in its performance. Unlike conventional springs, which exhibit a linear relationship between force and deflection, constant springs defy this trend, maintaining a steady force regardless of the displacement. This remarkable property stems from their ingenious design, which often incorporates intricate geometries and specialized materials.

The beauty of constant springs lies in their unwavering consistency. They provide a reliable and predictable force throughout their operating range, a quality that is highly sought after in various applications. Take, for instance, a spring-loaded mechanism in a delicate instrument. A constant spring ensures that the force applied remains consistent, preventing any fluctuations that could affect the instrument's accuracy. In contrast, a conventional spring, with its variable force, could introduce unwanted deviations, jeopardizing the precision of the device.

The unwavering consistency of constant springs has made them indispensable across a wide range of industries. Their versatility extends from delicate instruments to robust machinery, showcasing their remarkable adaptability. Let's explore some prominent applications:

Constant springs find a welcoming home in the world of precision instruments, where unwavering force is paramount. Consider the delicate balance of a spring-loaded scale, meticulously engineered to provide accurate measurements. A constant spring ensures that the scale consistently registers the correct weight, regardless of the load applied. This unwavering accuracy is essential for ensuring the reliability of these crucial instruments.

The automotive industry relies heavily on constant springs for smooth operation. In clutches and brakes, constant springs ensure consistent engagement and disengagement, guaranteeing reliable performance. This consistency is vital for maintaining a smooth driving experience, preventing sudden jolts or jerks that could compromise safety.

In the demanding realm of aerospace engineering, constant springs play a critical role in maintaining the stability and functionality of aircraft components. They ensure the consistent operation of flaps and control surfaces, providing reliable adjustments that are essential for safe and efficient flight.

The healthcare industry relies on constant springs for their precision and safety in medical devices. From surgical instruments to prosthetic limbs, constant springs ensure smooth operation and consistent force application. Their reliability in these critical applications is vital for the well-being of patients. For example, a constant spring used in a medical syringe ensures consistent force application, minimizing the risk of inaccurate dosage or discomfort for the patient.

The unique properties of constant springs have earned them a place of prominence in the world of engineering. Their unwavering consistency offers numerous advantages, setting them apart from conventional springs:

The most notable advantage of constant springs is their consistent force output. Regardless of the deflection, they maintain a steady force, eliminating variations that could affect performance and accuracy. This predictability is invaluable in applications where consistent force application is paramount.

Constant springs provide precise control over force application, allowing engineers to fine-tune mechanisms with greater accuracy. This precision is particularly vital in delicate instruments, where even minute deviations in force could compromise functionality.

Constant springs are known for their exceptional durability. Their consistent force application minimizes stress on the spring material, reducing the risk of fatigue and extending the lifespan of the component. This longevity is a crucial factor in applications where reliability is paramount.

Constant springs have become an integral part of our modern world, underpinning a wide range of technologies and applications. Their consistent force, precise control, and remarkable durability make them invaluable components in numerous industries. As technology continues to advance, constant springs will undoubtedly continue to play a pivotal role in shaping the future of engineering, offering new and innovative solutions to emerging challenges.

The power of constant springs lies not just in their unwavering consistency, but also in their remarkable adaptability. They have seamlessly integrated themselves into our lives, enhancing the precision of instruments, ensuring the smooth operation of machinery, and improving the safety of medical devices. As technology continues to advance, constant springs will undoubtedly continue to play a pivotal role, pushing the boundaries of engineering innovation and creating a world where consistency reigns supreme.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.