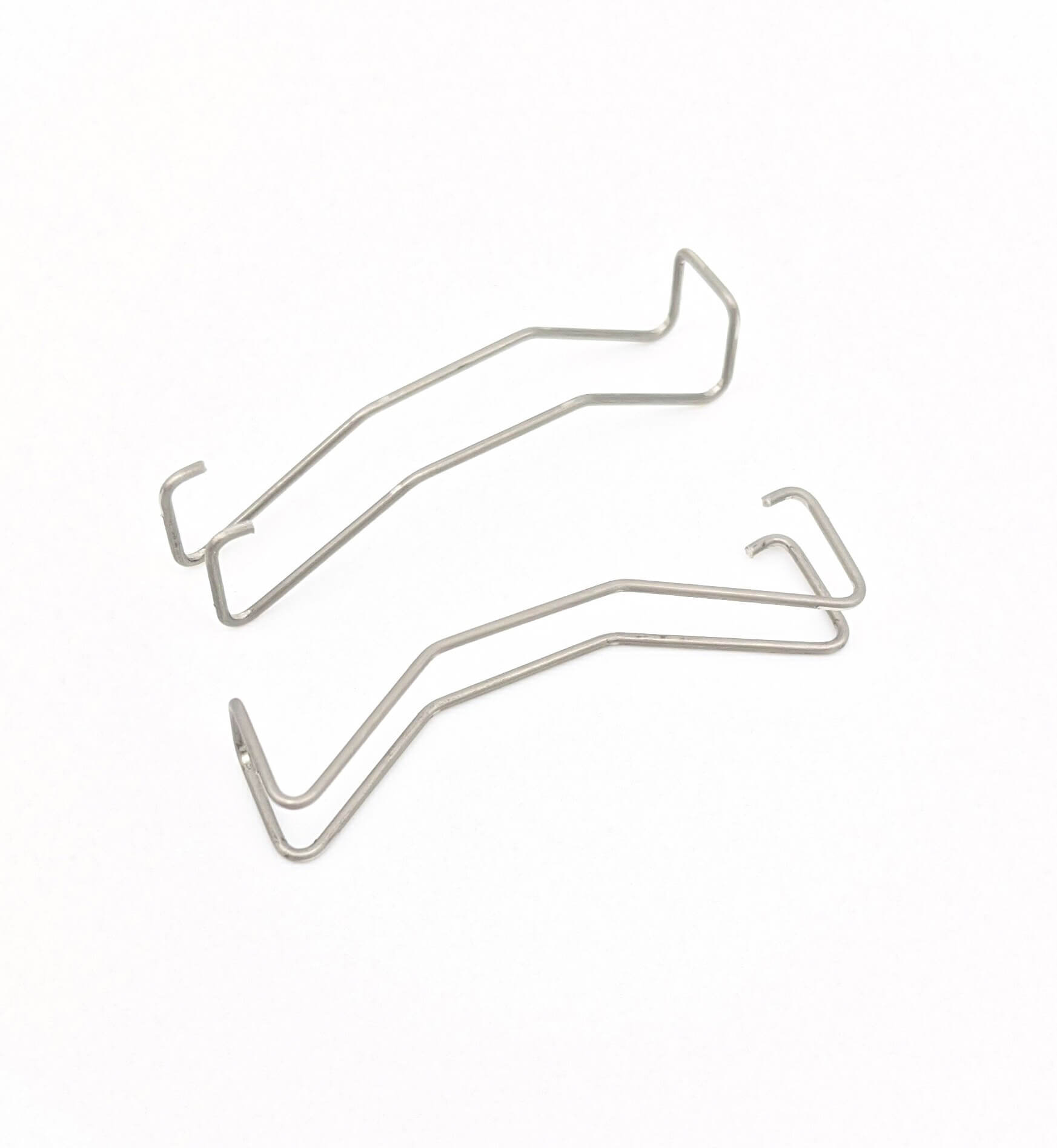

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered about the science behind compressing a coil spring? It's a seemingly simple act, but it involves a fascinating interplay of physics and engineering. This article will

Have you ever wondered about the science behind compressing a coil spring? It's a seemingly simple act, but it involves a fascinating interplay of physics and engineering. This article will delve into the mechanics of compression, exploring Hooke's Law, the concepts of spring constant and potential energy, and how these principles come into play when we squeeze a coil spring. We'll also look at various real-world applications of compressed coil springs, from their use in everyday objects like pens and car suspensions to more complex scenarios like shock absorbers and aerospace engineering.

At the heart of understanding the behavior of a coil spring lies Hooke's Law, a fundamental principle in physics. It states that the force required to compress or extend a spring is directly proportional to the displacement from its equilibrium position. In simpler terms, the harder you push or pull a spring, the further it will move. This relationship can be expressed mathematically as:

F = -kx

Where:

The negative sign indicates that the force exerted by the spring is always in the opposite direction to the displacement. For instance, if you compress a spring (positive displacement), the spring pushes back (negative force).

The spring constant (k) is a crucial parameter that determines how stiff or flexible a spring is. A higher spring constant indicates a stiffer spring, requiring more force to compress it. For example, a heavy-duty car suspension spring would have a much higher spring constant than a spring in a ballpoint pen.

When you compress a coil spring, you're actually storing energy within it. This stored energy is known as elastic potential energy. The amount of potential energy stored in a compressed spring is directly proportional to the square of the compression distance:

U = (1/2)kx²

Where:

Think of it like winding up a toy – you're storing energy in the spring, and as the toy unwinds, that stored energy is released, causing the toy to move.

Compressed coil springs are ubiquitous, playing critical roles in a wide range of applications, from the mundane to the highly sophisticated. Here are a few examples:

While coil springs are the most common type, other spring designs exist, each with unique properties and applications. Some notable examples include:

The humble coil spring, seemingly simple in design, is a testament to the power of physics and engineering. From the everyday objects that surround us to the sophisticated machinery that drives our world, compressed coil springs play a crucial role in countless applications. Understanding the principles of Hooke's Law and spring constant, along with the energy storage capabilities of springs, is essential for appreciating the vast impact these seemingly simple devices have on our daily lives.

As you go about your day, take a moment to appreciate the unseen springs that work tirelessly around you, silently enabling the smooth functioning of countless devices and systems. From the simple act of writing with a pen to the complex mechanics of aircraft, compressed coil springs continue to be a fundamental cornerstone of our technological world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.