Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

There's an undeniable charm to small wave springs. They're not just tiny pieces of metal; they're the unsung heroes of countless mechanical designs, adding a touch of resilience and precision

There's an undeniable charm to small wave springs. They're not just tiny pieces of metal; they're the unsung heroes of countless mechanical designs, adding a touch of resilience and precision to everything from delicate watches to powerful engines. In this article, we'll delve into the world of small wave springs, exploring their unique characteristics, diverse applications, and the reasons why they remain a crucial component in modern engineering.

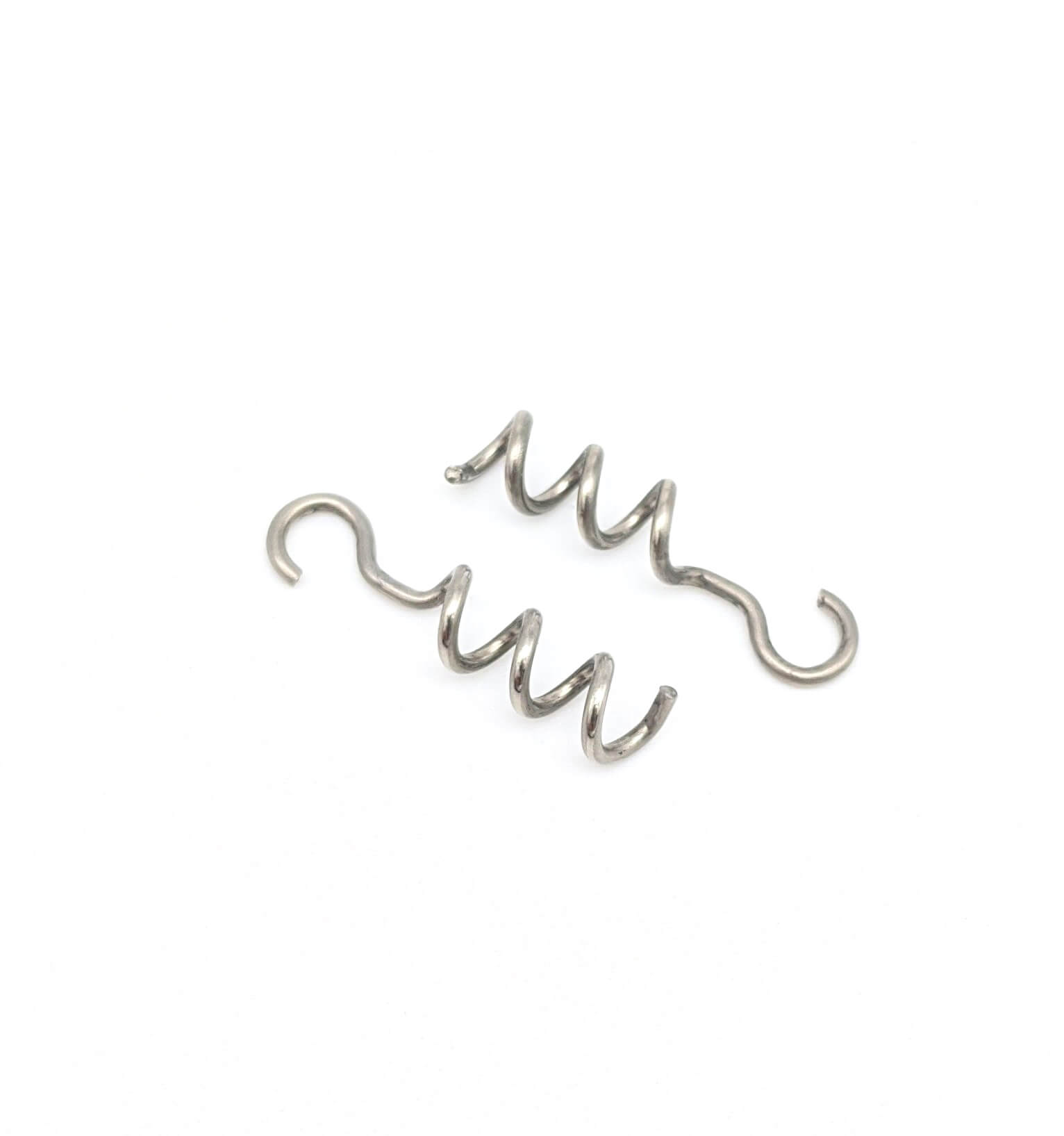

Imagine a spring that's not just a simple coil, but a series of waves, each one subtly curving to create a unique spring action. These are small wave springs, also known as corrugated springs, and their structure is what makes them stand out. Unlike conventional coil springs, which rely on a single helix, wave springs are made by compressing a flat strip of metal into a series of alternating waves, giving them a distinct, almost origami-like appearance. This unique design is what grants them their incredible strength, resilience, and flexibility.

Small wave springs offer a captivating blend of advantages that make them indispensable in a wide array of applications. Their compact size is perhaps their most notable feature. Because they're so small, they can be easily incorporated into tight spaces, making them ideal for use in miniature electronics, medical devices, and even jewelry. This size advantage, however, doesn't come at the cost of strength. In fact, small wave springs boast an astonishingly high strength-to-weight ratio. They can withstand tremendous forces while still maintaining their compact size, ensuring robust performance in even the most demanding situations.

Another key advantage is their ability to handle high loads. These springs can compress significantly without deforming or losing their springiness. This makes them perfect for applications where reliability is paramount, such as automotive components, aerospace parts, and industrial machinery. Small wave springs are also incredibly versatile. They can be customized in various shapes and sizes to meet the specific requirements of each application. You might find them acting as a spring in a tiny watch mechanism, holding delicate parts together, or providing crucial support in a powerful engine. Their adaptability ensures that they can be used in almost any situation where a compact, reliable spring is needed.

The versatility of small wave springs is truly remarkable. Their applications span across a vast range of industries, making them an integral part of modern engineering. Here are just a few examples of how small wave springs are used:

1. Electronics: In the world of electronics, where space is always at a premium, small wave springs are invaluable. They provide reliable clamping and contact force for delicate components like connectors, switches, and circuit boards. Imagine your smartphone or laptop; these tiny springs are likely working behind the scenes to ensure everything functions smoothly.

2. Medical Devices: The medical industry relies heavily on small wave springs. They're used in everything from pacemakers and heart valves to surgical instruments and drug delivery systems. Their biocompatibility, strength, and precision make them ideal for applications where safety and reliability are paramount.

3. Aerospace: In the demanding environment of aerospace, components need to be incredibly lightweight and robust. Small wave springs fit the bill perfectly. They're used in various aerospace applications, including satellite components, aircraft actuators, and even rocket engines, where their high strength and compact size are crucial for performance.

4. Automotive: The automotive industry relies on small wave springs for a wide range of components, from engine valves and fuel injectors to suspension systems and seat mechanisms. Their ability to handle high loads, vibrations, and temperature fluctuations makes them an essential part of keeping vehicles running smoothly and safely.

5. Industrial Machinery: In industrial machinery, where components need to withstand extreme wear and tear, small wave springs are essential. They're used in everything from pumps and compressors to conveyor belts and robotic arms, providing reliable force and support in demanding applications.

The world of small wave springs is constantly evolving, driven by ongoing research and development. Innovations are constantly emerging, leading to even smaller, stronger, and more versatile springs. These advancements are allowing small wave springs to penetrate even more applications, pushing the boundaries of what we consider possible in engineering. As we move towards miniaturization in various fields, small wave springs will likely play an even more vital role, shaping the future of technology and innovation.

Small wave springs might be tiny, but their impact is anything but insignificant. They are the backbone of countless mechanical designs, adding a touch of resilience, precision, and efficiency to everything they touch. From the smallest electronics to the largest industrial machinery, these springs continue to amaze us with their versatility and strength, proving that even the smallest things can have a big impact on our world.

Small wave springs are a testament to the power of engineering. Their unique design and remarkable capabilities offer a glimpse into the incredible potential of miniature components. As we continue to push the boundaries of technology, small wave springs will likely remain an indispensable part of the equation, shaping the future of innovation and ensuring that even the smallest details can make a big difference.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.