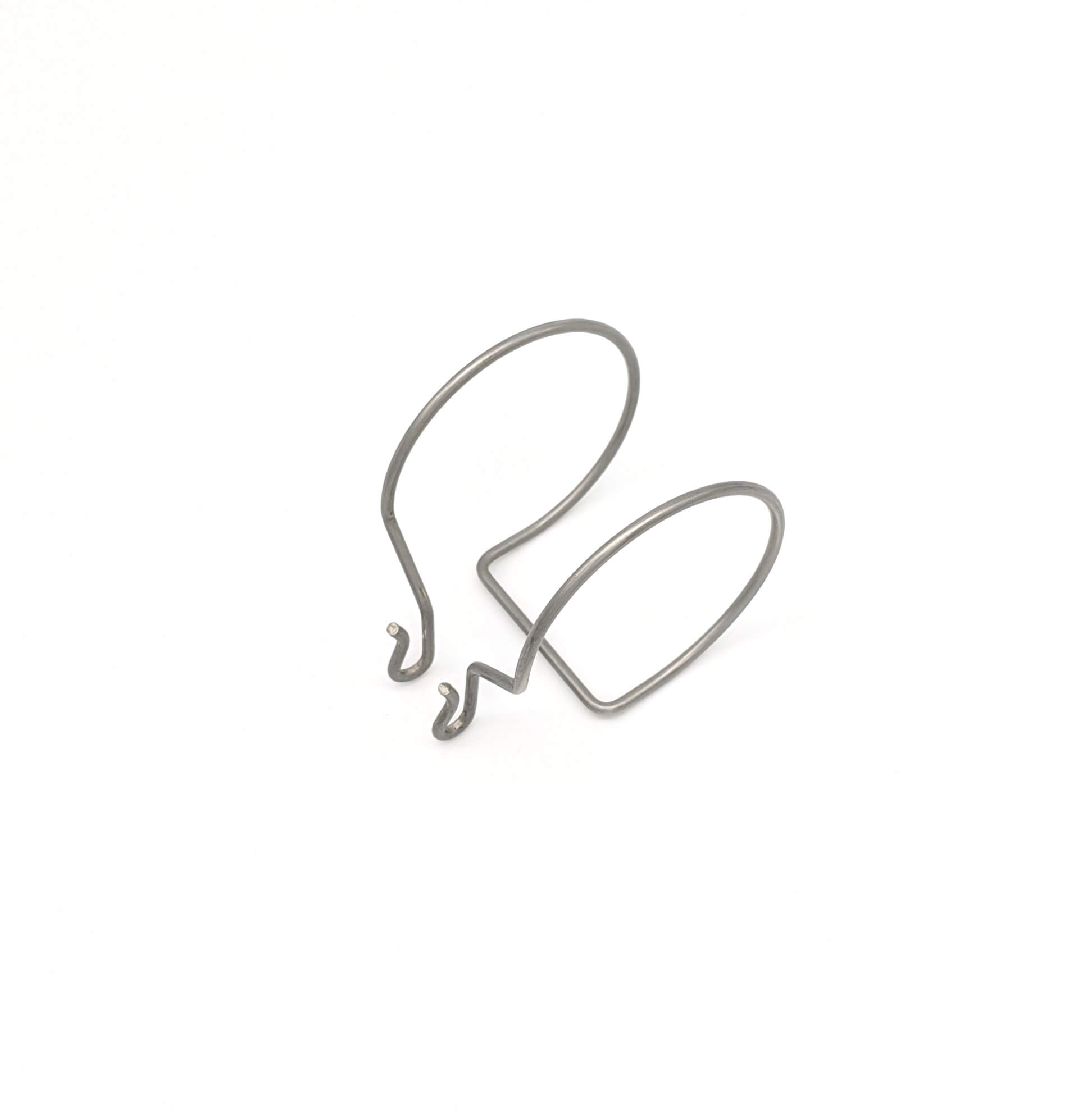

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring coils, also known as helical springs, are ubiquitous in our daily lives, quietly working behind the scenes to provide support, absorb shock, and store energy. From the humble door

Spring coils, also known as helical springs, are ubiquitous in our daily lives, quietly working behind the scenes to provide support, absorb shock, and store energy. From the humble door spring to the complex suspension systems in vehicles, spring coils are indispensable components in countless applications. This comprehensive guide delves into the fascinating world of spring coils, exploring their design, types, materials, and the science behind their operation.

Imagine a world without springs. Doors wouldn't close softly, car rides would be jarring, and even basic tasks like opening a pen would be far more challenging. Spring coils are often taken for granted, but their role in modern life is undeniable. They are essentially elastic devices that store and release mechanical energy, providing a multitude of benefits in various industries.

At the heart of a spring coil's functionality lies the principle of elasticity. When a spring coil is compressed or stretched, it stores potential energy due to the deformation of its material. This stored energy is then released as the spring returns to its original shape, exerting a force in the opposite direction of the applied load. The key to a spring coil's behavior is its spring constant, which represents its stiffness. A higher spring constant indicates a stiffer spring, requiring more force to deform it. This concept is fundamental to understanding how spring coils behave in different applications.

Spring coils come in a variety of types, each tailored to specific applications and load requirements. Two primary classifications are based on the direction of applied force:

Beyond these basic types, there are numerous variations, including torsion springs, constant-force springs, and variable-rate springs. Each variation offers unique characteristics and benefits, catering to the specific demands of different applications.

The material used to manufacture a spring coil is crucial for its strength, durability, and performance. Spring steel, with its high elastic modulus and strength-to-weight ratio, is the most common material. However, other metals, like stainless steel, bronze, and even titanium, are used for specific applications requiring corrosion resistance or other unique properties. The material selection depends on the intended application, environmental factors, and required load-bearing capacity.

The manufacturing process for spring coils involves coiling a wire around a mandrel, creating the helical shape. The wire is then heat-treated to achieve the desired strength and resilience. The manufacturing process involves various steps, including:

Modern spring coil manufacturing processes are highly automated, ensuring consistent quality and precision.

Spring coils are ubiquitous in our daily lives, powering a wide range of applications:

Their versatility and reliability make spring coils indispensable components in a vast array of industries and applications.

As technology advances, so too do the applications and designs of spring coils. Advancements in materials science have led to the development of high-performance alloys, enabling the creation of spring coils that are lighter, stronger, and more durable. Furthermore, advancements in manufacturing techniques have made it possible to produce spring coils with intricate shapes and tolerances, catering to increasingly demanding applications. As technology continues to evolve, we can expect to see further innovations in spring coil design and applications, pushing the boundaries of their capabilities.

Spring coils, often unseen but always present, are essential components in countless applications. They silently perform a multitude of functions, from absorbing shocks to storing energy, making our world a more efficient and comfortable place. As we continue to push the limits of technology, the role of spring coils is likely to become even more significant, serving as a cornerstone of countless innovative solutions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.