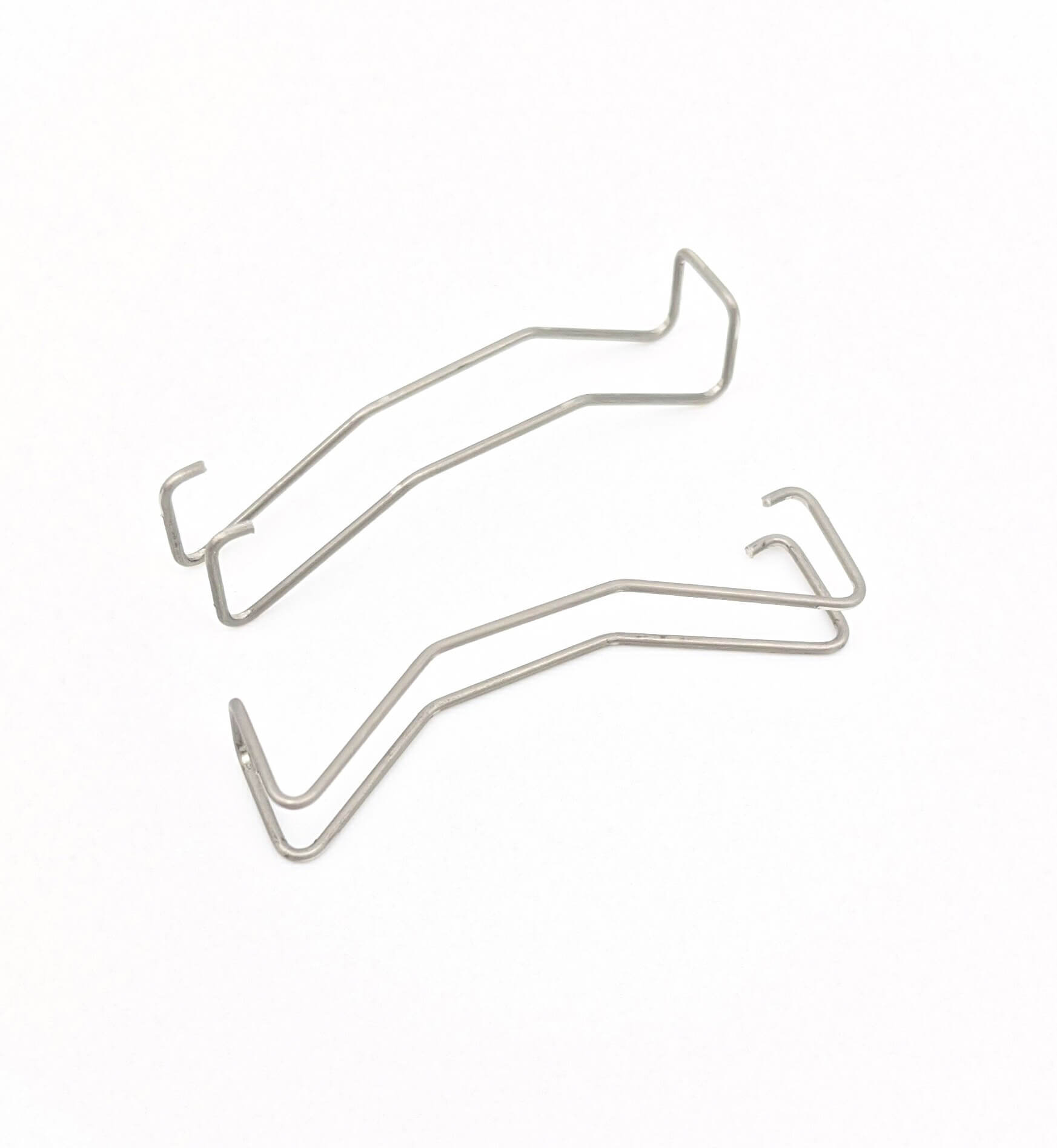

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Choosing the right spring for your application can be a challenge, especially when faced with the seemingly similar tension and torsion springs. While both are essential components in various mechanical

Choosing the right spring for your application can be a challenge, especially when faced with the seemingly similar tension and torsion springs. While both are essential components in various mechanical systems, they differ significantly in their design, functionality, and applications. Understanding these distinctions is crucial for engineers and designers to select the most suitable spring for optimal performance and longevity. This article delves into the core differences between tension and torsion springs, highlighting their unique characteristics and ideal use cases.

Tension springs, as their name suggests, are designed to resist pulling or stretching forces. They are typically coiled in a helical shape and function by storing potential energy when stretched and releasing it as they contract. You can imagine a tension spring as a small, flexible rubber band that resists being pulled apart.

Let's break down the key features of tension springs:

• Design: Tension springs are often manufactured with a hook or loop at each end, allowing for easy attachment to other components. The spring's diameter, wire thickness, and number of coils determine its strength and extension capacity.

• Applications: Tension springs are quite versatile and find use in a wide array of applications. They are commonly found in:

• Garage doors: Tension springs help to counterbalance the weight of the door, making it easier to open and close.

• Mechanical devices: They are used in various machines, such as clamps, spring-loaded mechanisms, and retracting mechanisms.

• Automotive components: Tension springs are essential in various automotive components, including suspension systems, door latches, and hood support systems.

Torsion springs, in contrast to tension springs, are designed to resist twisting forces. These springs are typically coiled into a helical shape with ends that are bent at an angle. They store potential energy when twisted and release it as they return to their original position. Think of a torsion spring as a twisty tie that resists being twisted beyond a certain point.

Let's delve into the distinguishing features of torsion springs:

• Design: Torsion springs are usually manufactured with a variety of end configurations, including straight ends, hooks, or loops, depending on the application. The spring's diameter, wire thickness, and the angle of its ends influence its twisting strength and rotational capacity.

• Applications: Torsion springs are frequently employed in applications that require controlled rotation or twisting forces. They are commonly found in:

• Appliances: Torsion springs are used in various household appliances, like washing machines, dryers, and refrigerators, for opening and closing doors and drawers.

• Automotive components: In cars and trucks, torsion springs are commonly used in suspension systems, window mechanisms, and power steering systems.

• Industrial machinery: They play a vital role in various industrial machinery, including robotics, automation systems, and precision equipment.

While both tension and torsion springs store and release potential energy, the key difference lies in how they resist force and the direction of that resistance:

• Force Resistance: Tension springs resist pulling or stretching forces, while torsion springs resist twisting or rotating forces.

• Direction of Force: Tension springs exert force along their axis, while torsion springs exert force perpendicular to their axis.

Selecting the appropriate spring type is crucial for optimal performance in your application. Here are some factors to consider when choosing between tension and torsion springs:

• Type of force: If your application requires resistance to pulling or stretching, a tension spring is the best choice. If it requires resistance to twisting or rotating forces, a torsion spring is the right fit.

• Application environment: Consider the operating environment, such as temperature, humidity, and potential corrosive factors, as they can affect spring performance.

• Force requirements: Determine the precise force needed for your application and choose a spring with the appropriate strength and extension/rotation capacity.

Tension and torsion springs are essential components in countless mechanical systems. Understanding the differences between them is crucial for engineers and designers to select the most suitable spring for their applications. By carefully considering the type of force, application environment, and force requirements, you can ensure that the chosen spring provides optimal performance and longevity. Whether it's resisting a pull, a twist, or something in between, the right spring can make a world of difference in the smooth operation and reliability of your mechanical systems.

Ultimately, choosing the right spring comes down to understanding the specific needs of your application. By carefully analyzing the factors discussed in this article, you can make informed decisions to optimize performance and ensure the longevity of your mechanical systems. Remember, the right spring can make all the difference.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.