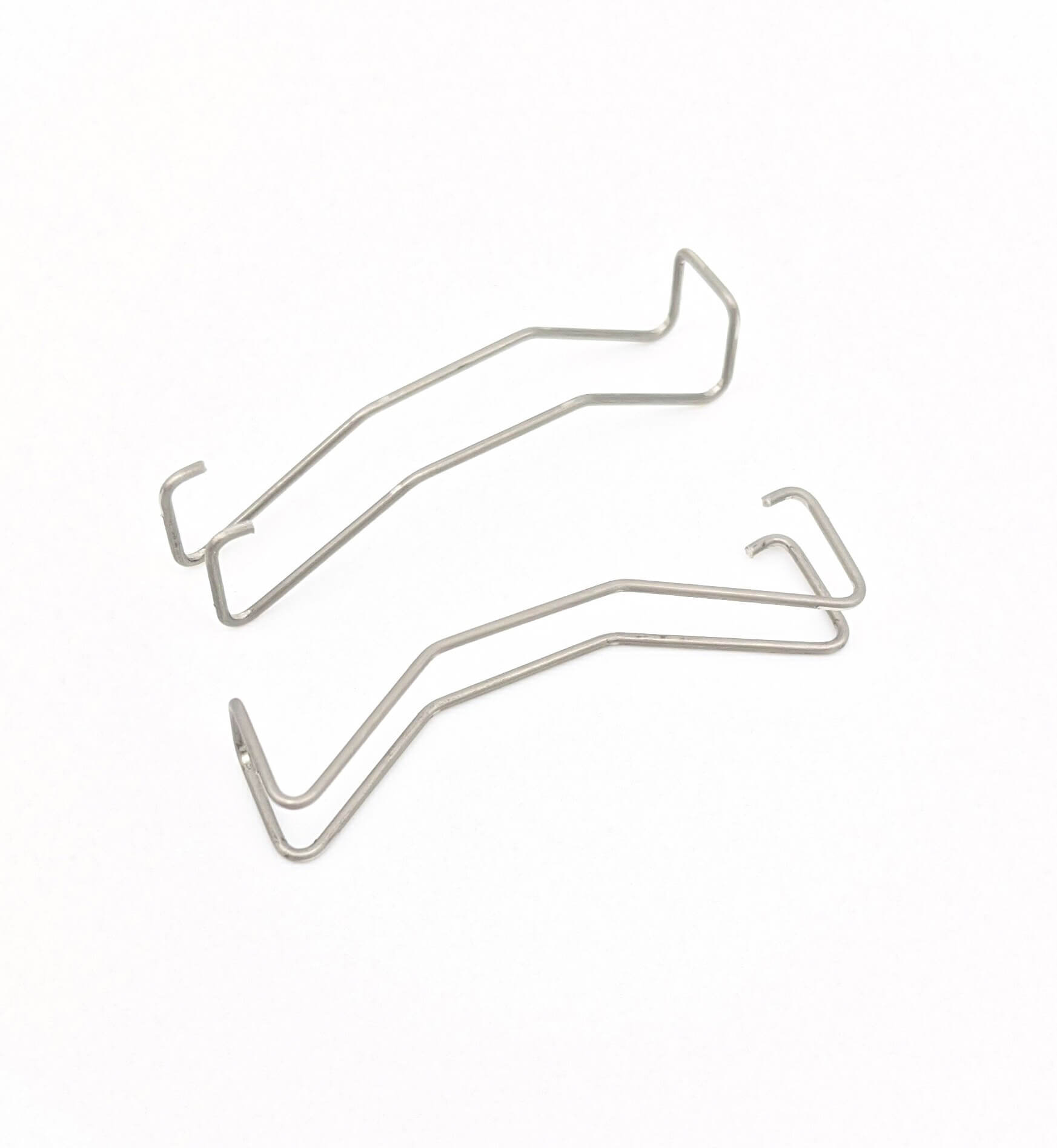

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

When it comes to mechanical design, springs play a crucial role in providing flexibility and storing energy. Two common types of springs are tension springs and torsion springs, each with

When it comes to mechanical design, springs play a crucial role in providing flexibility and storing energy. Two common types of springs are tension springs and torsion springs, each with unique characteristics and applications. While both types are essential in various industries, understanding their differences is vital for choosing the right spring for a specific purpose. This article delves into the nuances of tension springs and torsion springs, highlighting their distinct properties and applications. By the end of this read, you'll have a better understanding of which type of spring is best suited for your specific needs.

Tension springs, also known as extension springs, are designed to operate under a tensile load. Imagine a rubber band—when you pull on it, it stretches. Similarly, tension springs elongate when a force is applied to them. This type of spring is typically made of coiled wire with a hook, eye, or other attachment point at each end. The spring's force is generated by the resistance to being stretched beyond its natural length.

Now, where do we find these stretching marvels? They find their way into countless applications, such as:

Torsion springs, on the other hand, are designed to operate under a twisting force, also known as torque. Picture a metal coat hanger—when you twist it, it resists the twisting motion. Similarly, torsion springs resist rotation when a torque is applied to them. They are often made of a coiled wire with one end fixed and the other end free to rotate.

These twisting wonders are found in various applications, including:

So, what sets these two types of springs apart? Let's break it down:

When selecting a spring for your project, consider the following factors:

For example, if you are designing a door closer, a tension spring would be the better choice. But for a wind-up toy car, a torsion spring is more suitable.

Tension springs and torsion springs are both vital components in numerous mechanical systems. Understanding their differences is crucial for making informed decisions when selecting the right spring for your specific needs. Whether you need a spring to stretch, pull, twist, or rotate, there's a perfect spring out there waiting to add flexibility and function to your design. So, choose wisely, and let your creations spring to life!

In conclusion, tension springs and torsion springs are essential components in various applications. While both types are designed to store and release energy, their load application and direction of force differ significantly. Choosing the right type of spring depends on the specific requirements of your project, such as the load type, force requirements, and space limitations. Remember, understanding the differences between these two spring types can greatly enhance your mechanical design choices.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.