Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

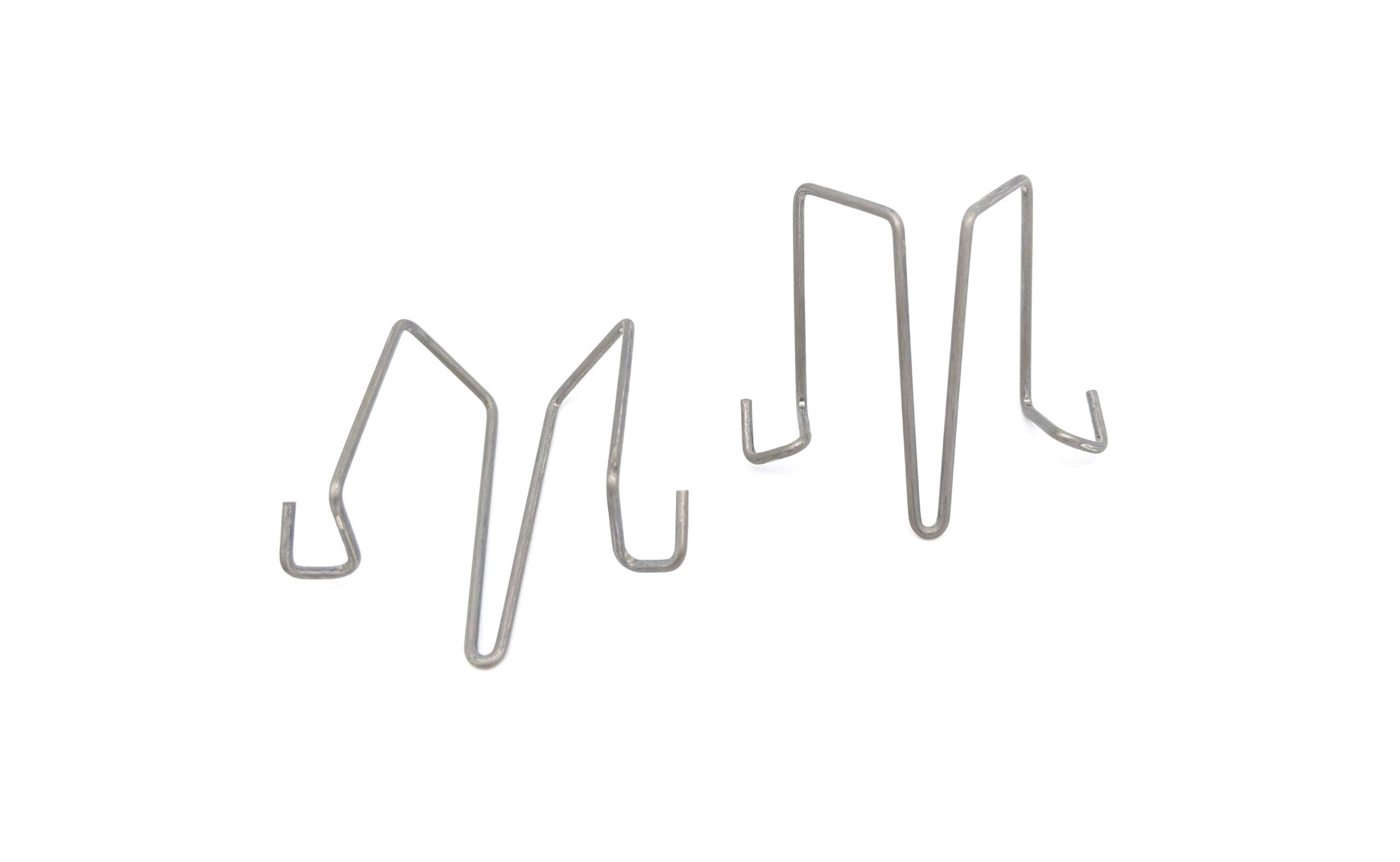

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical design, springs are essential components that provide force and motion, and they come in various forms, each tailored to specific functions. Among the most common

In the world of mechanical design, springs are essential components that provide force and motion, and they come in various forms, each tailored to specific functions. Among the most common types are tension springs and torsion springs. These seemingly similar components have distinct characteristics and applications, making it crucial to understand their differences when selecting the right spring for your project. This comprehensive guide will delve into the world of tension springs vs. torsion springs, exploring their workings, key features, advantages, and disadvantages to help you make an informed decision.

Tension springs are designed to resist stretching forces. Imagine a rubber band—it's a basic example of a tension spring. When you pull on a tension spring, it extends and stores energy. This energy is then released when the tension is removed, causing the spring to return to its original length. You'll find tension springs in a variety of applications, from simple tasks like holding a door open to more complex mechanisms like retracting cables in a machine.

Torsion springs, on the other hand, are designed to resist twisting forces. Think of a spring-loaded door closer—it's a perfect example of a torsion spring in action. When you twist a torsion spring, it stores energy in the form of rotational potential energy. The spring will then try to return to its original position when released, applying a torque to any object connected to it. Torsion springs are commonly used in applications like garage door openers, retractable pens, and even the balance wheels in watches.

The key difference between tension and torsion springs lies in how they store and release energy:

This fundamental difference dictates their specific applications and advantages.

Choosing between tension and torsion springs depends on the specific application and the requirements of your design. Consider these factors:

By carefully considering these factors, you can select the spring that best meets the needs of your project.

While tension and torsion springs are common, the world of springs extends far beyond these two basic types. You can find springs designed to resist compression, act as a constant force mechanism, or even change their stiffness dynamically. Understanding the basic principles behind tension and torsion springs lays a solid foundation for exploring the diverse world of spring technology and finding the ideal spring for your application.

In conclusion, understanding the distinct characteristics of tension and torsion springs is essential for choosing the right spring for your application. While tension springs excel in providing pulling and stretching forces, torsion springs offer a powerful solution for resisting twisting forces. By carefully considering the factors outlined in this guide, you can confidently select the spring that best suits your design requirements and optimize your mechanical systems. Remember, the right spring can make all the difference in the performance and longevity of your project.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.