Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

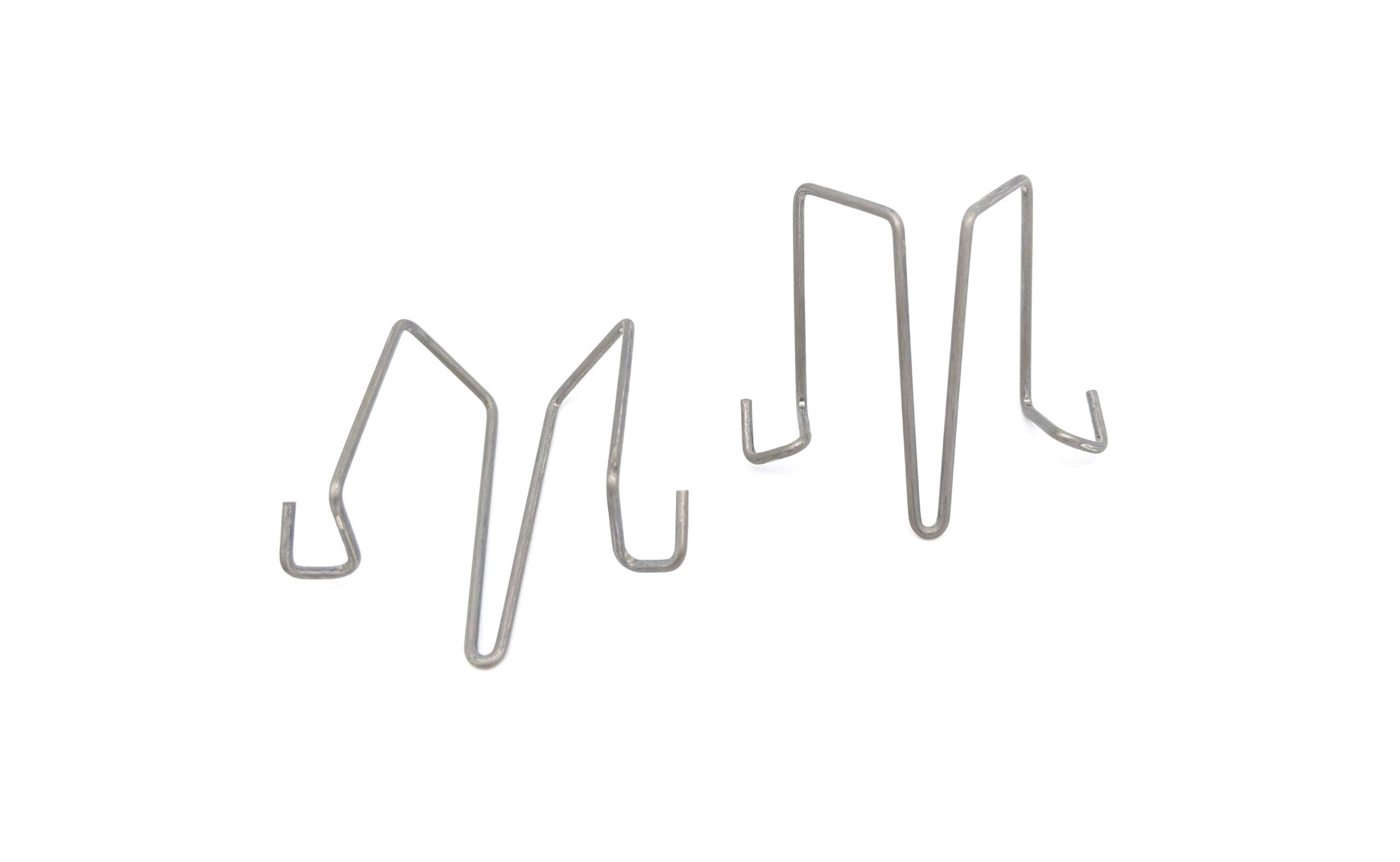

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Tension springs, often overlooked in our daily lives, are essential components in a wide variety of applications, from everyday household items to complex industrial machinery. They work silently and reliably,

Tension springs, often overlooked in our daily lives, are essential components in a wide variety of applications, from everyday household items to complex industrial machinery. They work silently and reliably, providing the force needed to return a device to its original position after being stretched. This article will delve into the world of tension springs, exploring their design, functionality, and the vast array of industries they power.

Imagine a spring that stretches instead of compresses. That's precisely what a tension spring is! These coiled marvels work by storing energy when stretched and releasing it to return to their original shape. Unlike their compression counterparts, they are designed to operate under tensile loads, with the spring elongating as the load is applied. This seemingly simple concept is at the heart of countless essential applications, making them indispensable in modern life.

The magic of a tension spring lies in its coiled construction. The wire is tightly wound around a central axis, creating a series of loops, or turns. When a force is applied, it stretches the spring, extending the wire and increasing the distance between the coils. This stretching action stores potential energy within the spring. When the force is removed, the spring's inherent elasticity kicks in, pulling the coils back together, releasing the stored energy and restoring the spring to its original length.

Tension springs are typically made from spring steel, a high-carbon alloy designed for its resilience and ability to withstand repeated stretching and recoiling. This choice of material ensures the spring's durability and long-lasting performance, even under demanding conditions. However, there are instances where alternative materials are used, like phosphor bronze or titanium, for applications requiring corrosion resistance.

Tension springs come in a wide variety of designs, each tailored to specific applications. Some common types include:

Tension springs are ubiquitous in our world, quietly working behind the scenes to make countless things function smoothly. Here are just a few examples:

The use of tension springs in manufacturing extends far beyond everyday objects. Their applications in industrial machinery, robotics, aerospace, and numerous other sectors are critical to ensuring precision, efficiency, and safety. These springs play vital roles in:

From the humble retractable pen to complex industrial machinery, tension springs are integral to our modern world. They work tirelessly, often unseen, providing the force needed to keep things moving and functioning as intended. Their reliable performance and versatility make them indispensable components in countless applications, proving that sometimes, the most powerful things come in small, coiled packages.

The next time you use a retractable pen or open a garage door, take a moment to appreciate the silent power of the tension spring working behind the scenes. These tiny, yet mighty, components are a testament to the ingenuity of engineering, silently making our world a more efficient and functional place.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.