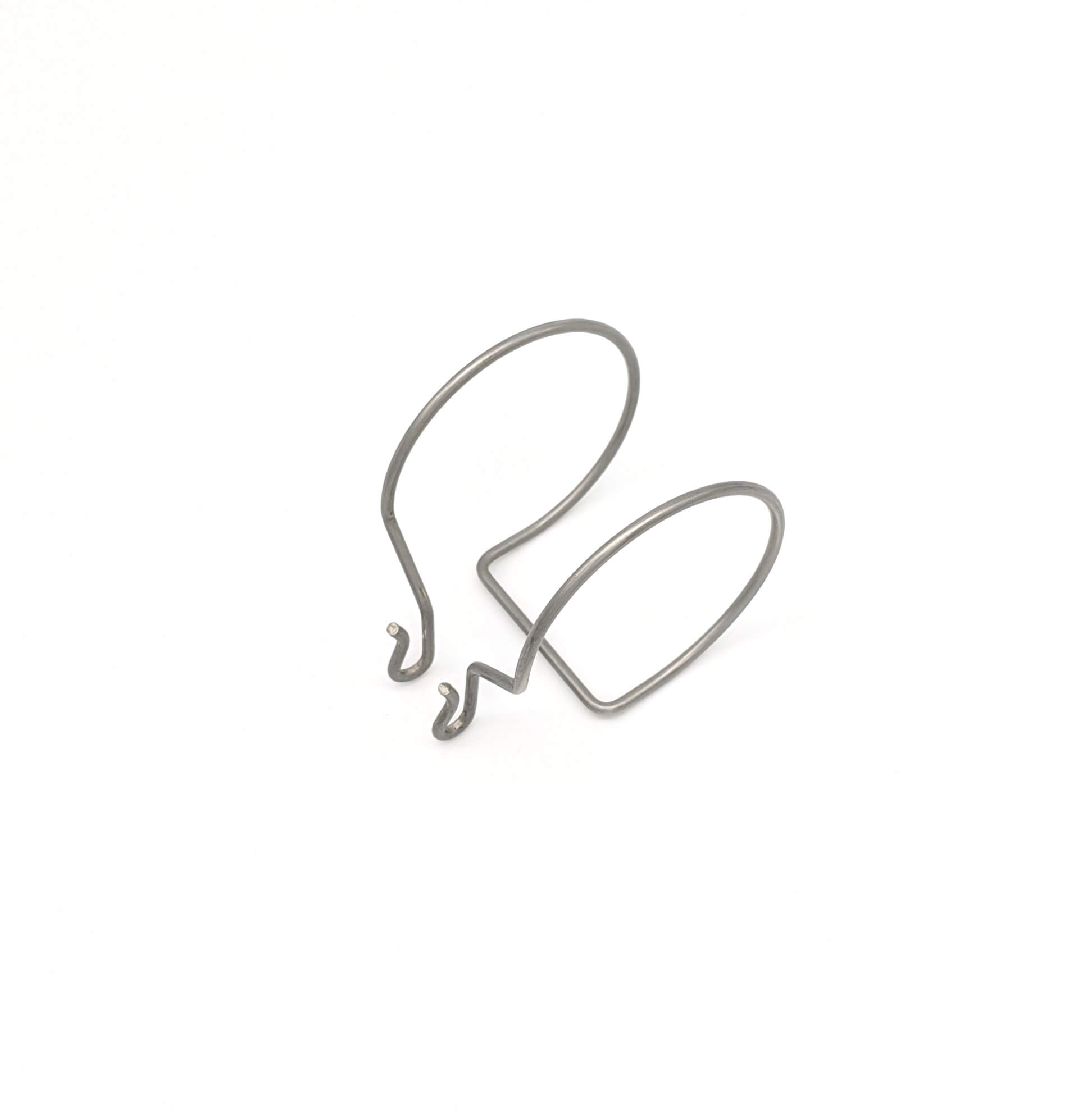

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Tension springs, those seemingly simple coiled wires, are often overlooked, yet they play a vital role in countless everyday objects and systems. From the smooth opening of a retractable pen

Tension springs, those seemingly simple coiled wires, are often overlooked, yet they play a vital role in countless everyday objects and systems. From the smooth opening of a retractable pen to the precise operation of a complex piece of machinery, tension springs are the unsung heroes that ensure functionality, safety, and convenience. In this article, we'll delve into the fascinating world of tension springs, exploring their diverse applications, working principles, and the crucial impact they have on our daily lives.

Tension springs are marvels of engineering, designed to store and release energy, providing a controlled force for various functions. Their unique design, with coiled wire tightly wound around a central axis, allows them to stretch under tension, storing potential energy like a compressed spring. When released, this stored energy is converted into a force, driving a mechanism or providing a spring-loaded action.

Think about a retractable pen, for instance. The humble spring inside allows you to smoothly extend and retract the pen tip with just a gentle push or pull. This seemingly simple act is powered by the tension spring, which stores energy as you extend the pen and releases it as you retract it, ensuring a smooth, controlled movement. The same principle applies to countless other applications, from the simple to the complex.

Tension springs are ubiquitous, silently working behind the scenes in a vast array of applications. In your home, they power the retractable doorstop, keep your clothesline taut, and allow for smooth operation of your window blinds. They even play a vital role in the workings of your washing machine, ensuring even distribution of clothes during the spin cycle.

Stepping beyond the household, tension springs are crucial components in a wide range of industries. In automotive applications, they power the latching mechanism of doors and hoods, ensuring proper closure and security. In manufacturing, they are employed in various machines, from conveyor belts to packaging systems, contributing to smooth and efficient operation. They even play a critical role in medical devices, such as retractors and clamps, aiding in surgical procedures.

The effectiveness of a tension spring hinges on the careful selection of materials and the precision of its design. Materials commonly used for tension springs include steel, stainless steel, and music wire, each offering specific properties for different applications. Steel springs are typically chosen for their strength and durability, while stainless steel springs excel in corrosion resistance. Music wire, renowned for its high tensile strength and elasticity, is often preferred for applications requiring a delicate yet powerful spring action.

The design of a tension spring is equally critical, influencing its performance and lifespan. Factors such as the wire diameter, coil diameter, number of coils, and free length all play a role in determining the spring's force, elongation, and overall functionality. A skilled engineer will carefully consider these parameters to create a tension spring that meets the specific demands of the application.

Selecting the appropriate tension spring is crucial for ensuring optimal performance and longevity in any application. Here are some key factors to consider when making your choice:

By carefully evaluating these factors, you can ensure that you choose a tension spring that meets the specific demands of your project, leading to optimal performance and reliability.

Tension springs, despite their simplicity, are constantly evolving with advancements in materials science, manufacturing techniques, and design principles. New alloys and composite materials are being developed, offering enhanced properties like higher tensile strength, improved corrosion resistance, and greater flexibility. These advancements allow for the creation of smaller, lighter, and more durable tension springs, expanding their applications and opening up possibilities for new innovations.

Moreover, the rise of 3D printing and additive manufacturing is revolutionizing the production of tension springs. These technologies offer unprecedented flexibility in creating complex geometries and custom designs, allowing for the production of highly specialized tension springs tailored to specific needs. This opens up exciting opportunities for creating bespoke solutions for demanding applications, where traditional manufacturing methods fall short.

Tension springs, though often unnoticed, are crucial components in countless everyday objects and systems. Their ability to store and release energy provides a controlled force, enabling a wide range of functions from simple tasks to complex operations. The future of tension springs is bright, with ongoing innovations and advancements expanding their applications and increasing their impact on our lives.

As we continue to develop new technologies and explore new applications, tension springs will continue to play a vital role, providing the power and precision necessary to make our world work smoothly and efficiently. So next time you encounter a retractable pen, a doorstop, or any other object powered by a tension spring, take a moment to appreciate this unsung hero of engineering, silently working behind the scenes to make our lives easier and more convenient.

From the retractable pen in your pocket to the intricate mechanisms of industrial machinery, tension springs are truly ubiquitous. Their simplicity belies their remarkable power and versatility, making them essential components in a wide array of applications. As we continue to explore the potential of these humble but essential components, tension springs will undoubtedly continue to play a pivotal role in shaping the world around us.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.