Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Tension springs are essential components in various mechanical systems, providing the necessary force to maintain tension and perform specific functions. Selecting the right tension spring is crucial to ensure optimal

Tension springs are essential components in various mechanical systems, providing the necessary force to maintain tension and perform specific functions. Selecting the right tension spring is crucial to ensure optimal performance and longevity of your application. This comprehensive guide explores the various factors involved in choosing tension springs by size, providing insights into the different types, materials, and specifications to consider. We will delve into the intricacies of understanding tension spring properties, exploring their applications, and offering practical advice for choosing the perfect spring for your specific needs.

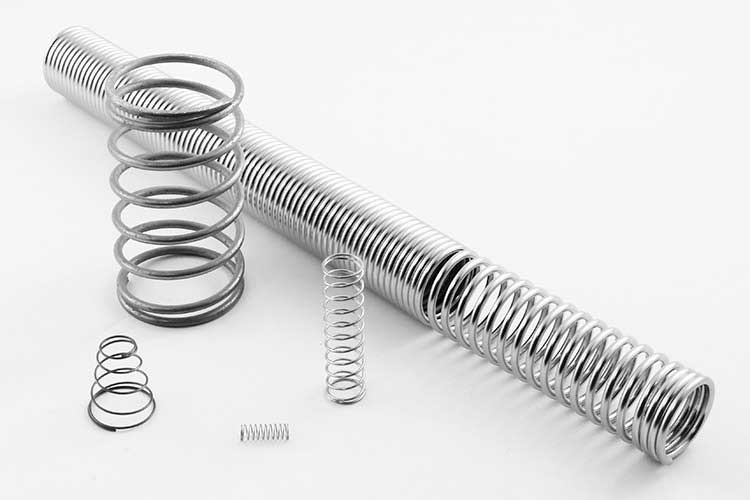

Tension springs, also known as extension springs, are coiled metal components designed to store and release energy when stretched. They are typically made from high-quality steel wire, but other materials like stainless steel, music wire, and phosphor bronze may be used depending on the application requirements. Their unique design allows them to exert a pulling force when extended, making them ideal for a wide range of mechanical and industrial applications.

The primary function of a tension spring is to provide resistance against stretching. When a force is applied to a tension spring, it elongates, storing potential energy. As the force is released, the spring returns to its original length, releasing the stored energy. This characteristic makes them essential for various applications requiring controlled movement, retraction, or tension.

When selecting tension springs by size, several crucial factors come into play to ensure compatibility and optimal performance with your application. These include:

The wire diameter determines the spring's strength and load capacity. A larger wire diameter corresponds to a stronger spring capable of handling heavier loads. However, thicker wires also increase spring stiffness and may affect its overall flexibility. The choice of wire diameter depends on the specific force requirement and the desired spring characteristics.

The free length of the tension spring refers to its unstretched length. This parameter is crucial for determining the spring's working range and its ability to extend and retract without exceeding its limits. The spring's free length needs to be sufficient to accommodate the desired extension and ensure smooth operation.

The spring index, calculated by dividing the mean coil diameter by the wire diameter, is a significant factor influencing spring characteristics. A higher spring index generally results in a more flexible spring, while a lower index leads to a stiffer spring. The ideal spring index depends on the application's specific requirements and the desired spring stiffness.

The material choice for the tension spring plays a crucial role in its strength, durability, and resistance to corrosion. Common materials include:

The end types of a tension spring determine how it is attached to the system and affect its overall performance. Common end types include:

The spring rate, also known as the spring constant, represents the force required to stretch the spring by a unit length. This parameter is crucial for determining how much force the spring will exert at a given extension. A higher spring rate indicates a stiffer spring, while a lower spring rate indicates a more flexible spring.

Tolerance refers to the allowable deviation from the specified dimensions of the tension spring. It is important to consider tolerance levels to ensure compatibility and smooth operation with other components in your application.

The number of coils in a tension spring affects its overall length and stiffness. More coils generally result in a longer and more flexible spring, while fewer coils lead to a shorter and stiffer spring.

Tension springs find applications in numerous industries and sectors, including:

To ensure the right tension spring selection, follow these steps:

Selecting the right tension spring is crucial for ensuring optimal performance and longevity of your application. By considering factors such as wire diameter, spring length, spring index, material type, spring end types, spring rate, tolerance, and number of coils, you can choose the perfect spring for your specific needs. Remember to consult with a spring manufacturer to ensure you select the most appropriate spring for your application. With the right tension spring, you can ensure smooth operation, reliable performance, and extended lifespan for your mechanical systems.

In conclusion, tension springs by size are essential components in various mechanical systems, providing the necessary force to maintain tension and perform specific functions. Understanding the factors involved in selecting tension springs, including their properties, applications, and specifications, is crucial for ensuring optimal performance and longevity of your application. By carefully considering these factors, you can choose the perfect tension spring to meet your specific needs and achieve seamless operation in your mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.