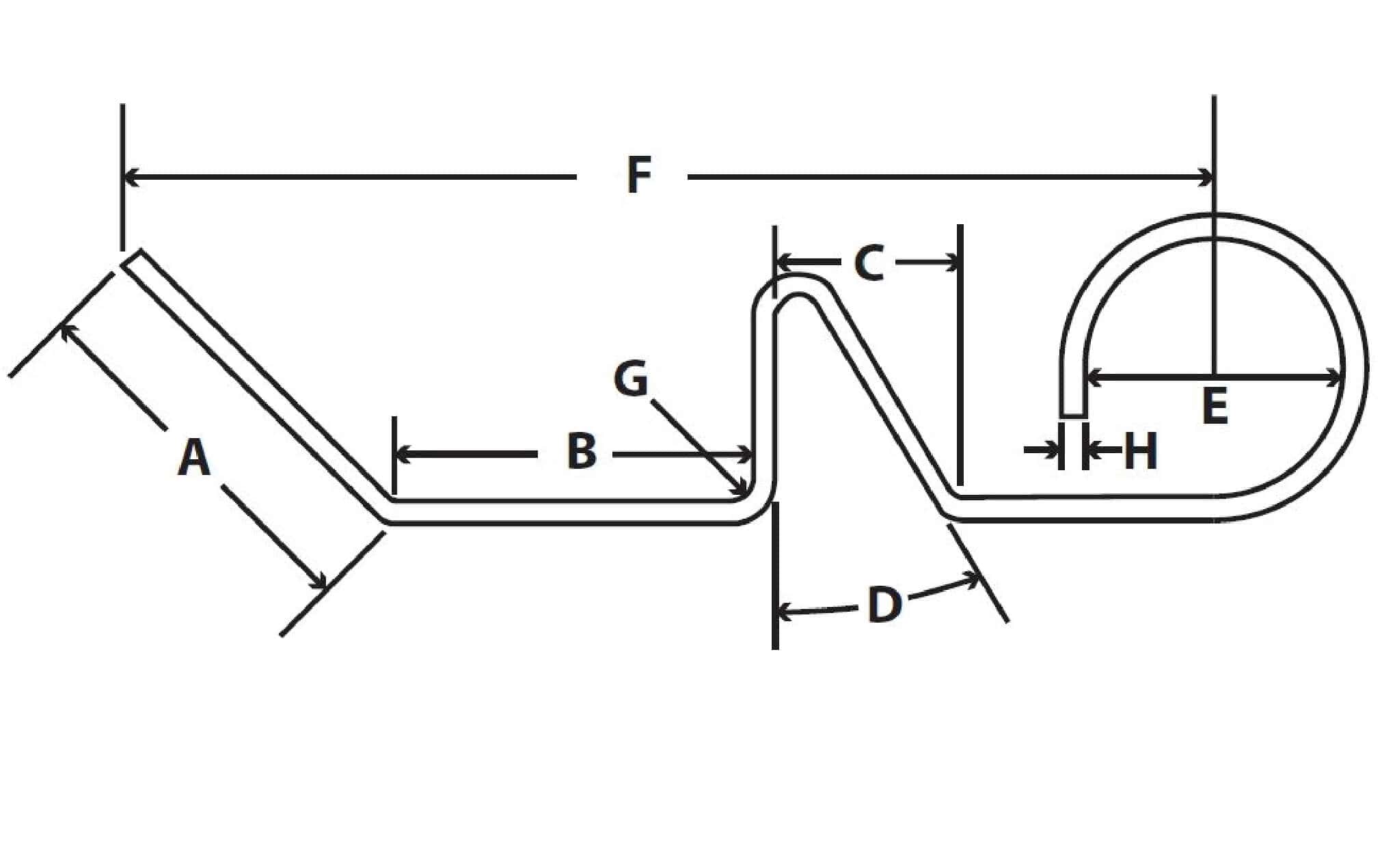

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Tension springs, often referred to as extension springs, are essential components in countless mechanical and industrial applications. Their unique ability to store and release energy through stretching makes them indispensable

Tension springs, often referred to as extension springs, are essential components in countless mechanical and industrial applications. Their unique ability to store and release energy through stretching makes them indispensable for various functions, from holding doors open to providing a springy return mechanism in retractable pens. This comprehensive guide delves into the intricacies of tension springs, covering their construction, types, applications, and selection criteria.

Tension springs, as the name suggests, are designed to store and release energy when stretched. Unlike compression springs that resist compression, tension springs are meant to resist stretching. They typically consist of a coiled wire that expands when a force is applied, and then contracts back to its original shape when the force is removed. The stored energy is then released, creating a springy effect.

The construction of tension springs involves a few key elements:

Tension springs come in a variety of configurations to suit different applications. Some common types include:

Tension springs are ubiquitous in modern life. Some common applications include:

Choosing the appropriate tension spring for a specific application requires careful consideration of several factors:

Tension springs offer several advantages over other types of springs, making them a popular choice in many applications:

Tension springs are essential components in countless mechanical and industrial applications. Their ability to store and release energy through stretching makes them invaluable for various functions. Understanding their construction, types, applications, and selection criteria is crucial for choosing the right spring for any given project. By considering factors such as required force, extension length, spring rate, material, and end attachments, you can ensure that your tension spring performs reliably and effectively for years to come.

As a versatile and reliable component, tension springs continue to play a crucial role in countless industries and aspects of our daily lives. Their unique ability to store and release energy through stretching makes them a valuable asset for engineers, designers, and manufacturers alike. By understanding the fundamentals of tension springs, you can effectively incorporate them into your projects, ensuring optimal performance and efficiency.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.