Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

When it comes to the world of springs, it can be easy to get confused about the various types and their specific applications. Two common types often causing a bit

When it comes to the world of springs, it can be easy to get confused about the various types and their specific applications. Two common types often causing a bit of head-scratching are tension springs and torsion springs. While they might sound similar, they have distinct functions and are used in vastly different scenarios. This article will delve into the unique characteristics of each spring type, clarifying the differences and explaining how they are applied in everyday life.

Imagine a spring that is designed to lengthen when you apply force to it. That, in essence, is a tension spring. These springs are all about pulling and stretching. Think of the spring in a retractable pen or the one that holds a screen door closed. When you pull on a tension spring, it extends and stores energy, and when released, it retracts back to its original position.

Now, picture a spring that reacts to a twisting force. This is where torsion springs come into play. These springs are designed to twist or rotate when you apply torque to them. A common example is the spring in a clothespin. As you squeeze the clothespin, you're twisting the torsion spring, which provides the clamping force. Other examples include springs found in garage door openers or in certain types of mechanical clocks.

So, how can you differentiate between tension and torsion springs? Here's a simple breakdown:

Essentially, tension springs work with linear forces, while torsion springs work with rotational forces.

Tension and torsion springs are incredibly versatile and find their way into a wide range of applications. Here are a few examples:

Selecting the appropriate type of spring for a specific application is paramount. The choice depends on factors such as the forces involved, the required movement, and the overall design of the system.

Remember, tension and torsion springs are just two of many spring types. Other categories include compression springs, constant force springs, and variable spring types, each offering unique characteristics and applications.

Understanding the differences between tension springs and torsion springs is crucial for anyone working with mechanical systems or designing products. By recognizing their individual strengths and applications, you can choose the perfect spring for your specific needs, ensuring optimal performance and longevity. After all, a well-chosen spring can be the key to smooth operation and reliable function in a wide range of applications.

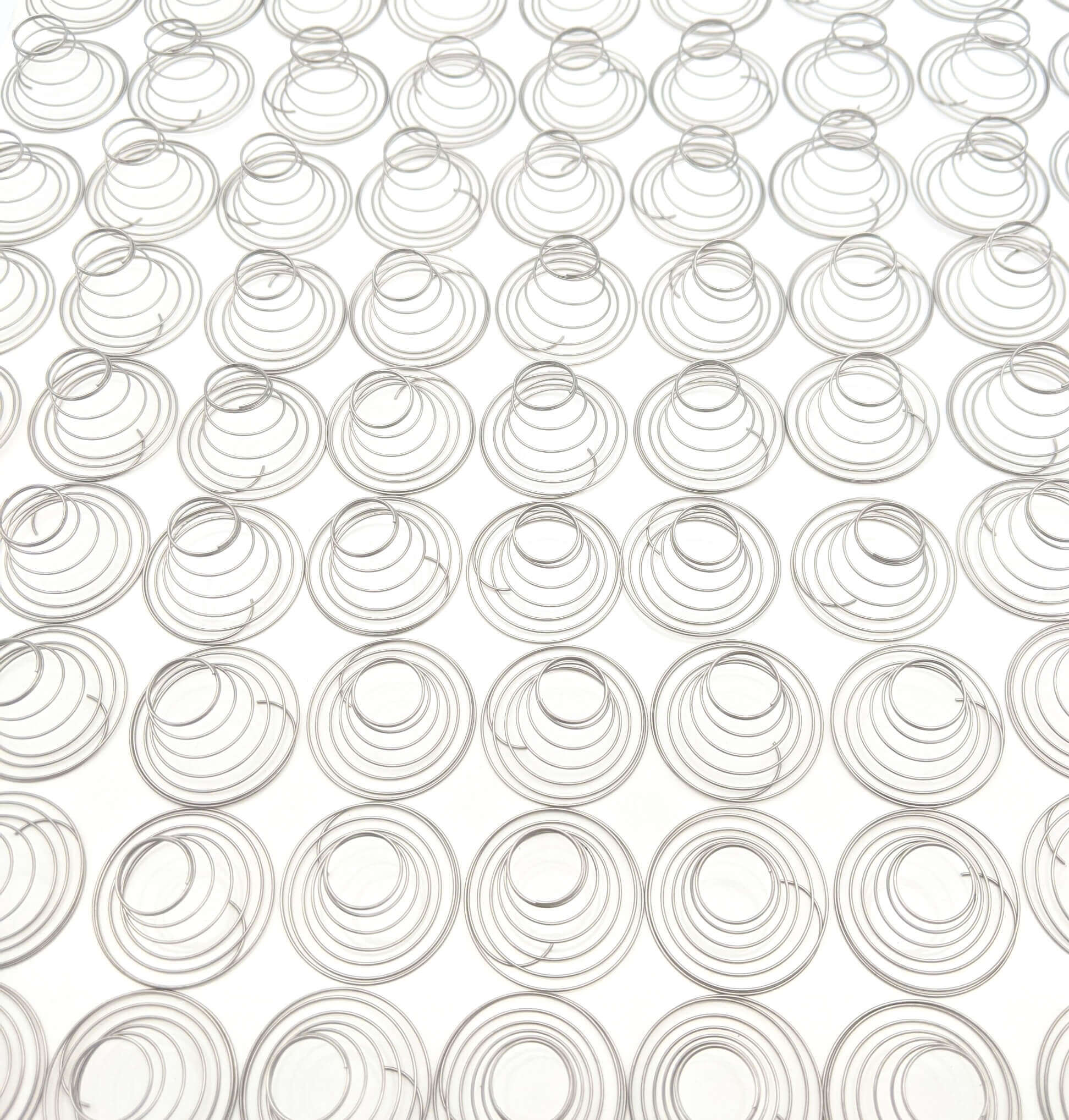

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.