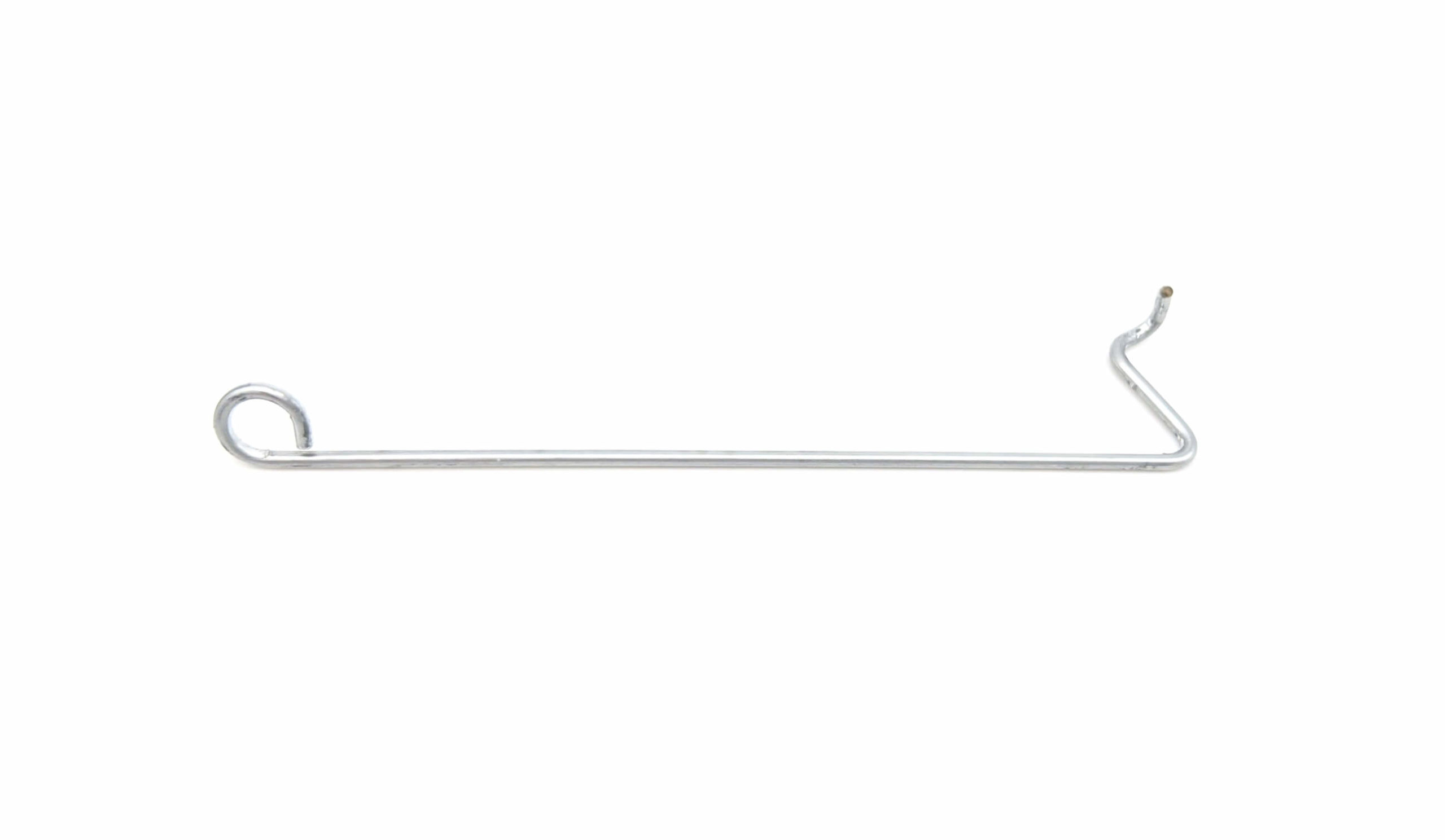

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Choosing the right tension spring for your application is crucial for ensuring proper functionality and longevity. This guide explores the essential aspects of tension spring size charts, their purpose, and

Choosing the right tension spring for your application is crucial for ensuring proper functionality and longevity. This guide explores the essential aspects of tension spring size charts, their purpose, and how to effectively use them. We will delve into key parameters, understanding the relationship between spring size, material, and performance. Whether you're a seasoned engineer or a DIY enthusiast, this comprehensive guide will equip you with the knowledge to select the optimal tension spring for your project.

Tension spring size charts are invaluable tools for selecting the appropriate spring for a specific application. They provide a detailed overview of spring dimensions, material properties, and load capacities. These charts are organized in a systematic manner, making it easy to identify suitable springs based on your requirements.

Think of a tension spring size chart as a roadmap for your spring selection journey. It guides you through the key factors to consider, such as spring diameter, wire diameter, free length, and spring rate. By understanding the relationships between these parameters, you can confidently choose the spring that best meets your needs.

Before diving into the specifics of tension spring size charts, let's understand the crucial parameters that determine a spring's performance:

1. **Spring Diameter (OD):** The outside diameter of the spring coil, measured in inches or millimeters. It influences the spring's overall size and the amount of force it can exert.

2. **Wire Diameter (WD):** The thickness of the wire used to create the spring coil, also measured in inches or millimeters. A larger wire diameter typically translates to a stronger spring.

3. **Free Length (FL):** The length of the spring when it's unloaded, measured in inches or millimeters. Free length determines the maximum extension the spring can achieve before reaching its limit.

4. **Spring Rate (K):** The amount of force required to extend the spring by one unit of length (typically inches or millimeters). A higher spring rate indicates a stiffer spring.

Tension spring size charts are usually arranged in a tabular format, with columns representing different parameters and rows showcasing specific spring configurations. The chart might include information on:

1. **Spring Dimensions:** OD, WD, FL, and the number of coils.

2. **Material Properties:** The type of spring steel used, such as stainless steel or music wire.

3. **Load Capacities:** Maximum load the spring can withstand without permanent deformation.

4. **Spring Rate (K):** Measured in pounds per inch (lb/in) or Newtons per millimeter (N/mm).

5. **Deflection Limits:** Maximum extension the spring can undergo before failing.

To effectively use a tension spring size chart, follow these steps:

1. **Identify Your Needs:** Determine the required load, extension, and other performance characteristics for your application.

2. **Match Your Parameters:** Locate the rows in the chart that match your load, extension, and desired spring rate.

3. **Consider Material:** Choose a material that suits your environment and application, considering factors like corrosion resistance and temperature tolerance.

4. **Verify Spring Dimensions:** Ensure the chosen spring's OD, WD, and FL are compatible with your design.

5. **Consult with Manufacturers:** If you have complex or critical applications, consulting with a spring manufacturer is highly recommended.

While tension spring size charts provide a great starting point, it's important to understand that they are not always exhaustive. You may need to consider additional factors depending on your specific needs.

1. **Environmental Considerations:** Factors like temperature, humidity, and corrosive environments can significantly impact spring performance.

2. **Operating Frequency:** The number of cycles the spring will undergo during its lifespan influences its fatigue life.

3. **Shock and Vibration:** Applications involving shock or vibration require springs that can withstand these forces.

4. **Safety Factors:** Incorporate safety factors to account for potential variations in load and environmental conditions.

Tension spring size charts are essential resources for engineers and DIY enthusiasts alike. By understanding their structure and key parameters, you can confidently choose the optimal tension spring for your project. Remember to consider all relevant factors, consult with experts when necessary, and prioritize safety in your selection process. With the right spring, you can ensure smooth operation, longevity, and a reliable performance in your applications.

Navigating tension spring size charts empowers you to select the perfect spring for your needs. By considering key parameters, material properties, and environmental factors, you can optimize your designs and achieve optimal spring performance. Remember to consult with experts for complex applications and always prioritize safety in your spring selection process. With a well-informed approach, you can ensure the success of your projects and enjoy the benefits of a robust and reliable tension spring.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.