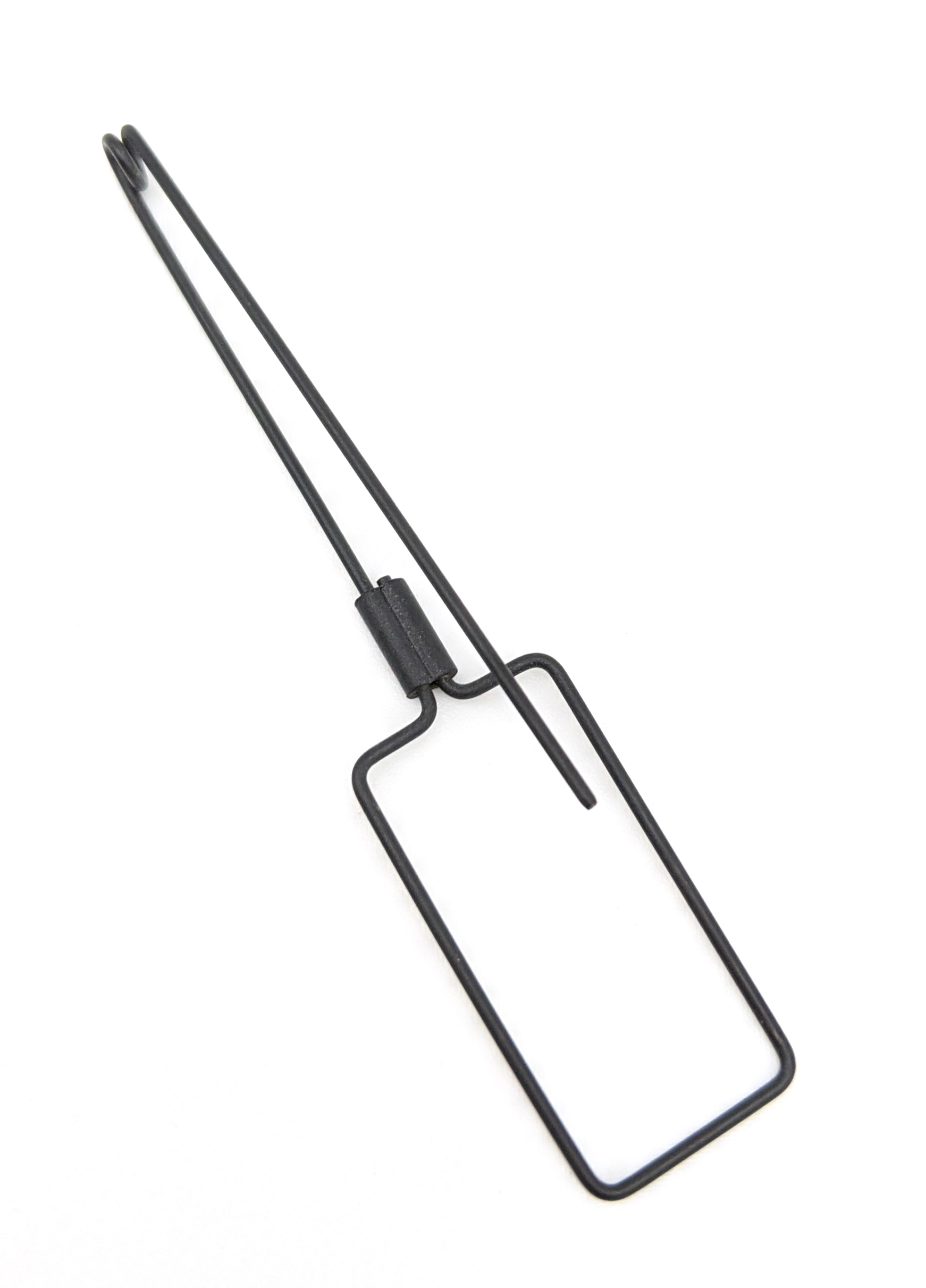

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Choosing the right tension spring can be a daunting task, especially if you are unfamiliar with the various factors that influence spring selection. This article serves as your ultimate guide

Choosing the right tension spring can be a daunting task, especially if you are unfamiliar with the various factors that influence spring selection. This article serves as your ultimate guide to tension spring sizing, providing a comprehensive explanation of what tension spring size charts are, how to read them, and how to choose the perfect spring for your specific application. We'll delve into the intricacies of spring parameters, explore the importance of choosing the correct tension spring size, and provide practical tips to make the process easier.

Tension spring size charts are invaluable tools for engineers and designers working with tension springs. These charts provide a standardized format for presenting information about various tension spring sizes, materials, and properties. They are essential for selecting the optimal spring for a given application, ensuring both proper function and longevity.

Tension spring size charts typically include the following key parameters:

Understanding the parameters listed above is crucial to effectively using a tension spring size chart. When selecting a spring, you need to consider the specific requirements of your application. For instance:

The size chart will typically have rows representing various wire diameters and columns representing different spring outer diameters. By finding the intersection of the desired wire diameter and outer diameter, you can access the information regarding that specific spring configuration. You can then use the spring rate and other relevant parameters to compare different spring sizes and choose the one that best matches your needs.

Choosing the right tension spring size is critical for the success of your design. A spring that is too weak might not provide enough force, while a spring that is too stiff could lead to premature failure or damage to other components. Here are some tips to help you make an informed decision:

Here are some additional tips for working with tension spring size charts:

In conclusion, tension spring size charts are essential tools for engineers and designers working with tension springs. By understanding the key parameters, how to read the charts, and the tips for selection, you can confidently choose the perfect spring for your application. Remember, the right spring size ensures proper function, durability, and optimal performance in your design. Always err on the side of caution and seek expert guidance when necessary. With careful planning and a thorough understanding of these principles, you can achieve successful spring selection for any application.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.