Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Strut springs, often overlooked but crucial components in various applications, play a vital role in supporting loads and providing stability. These resilient elements are commonly found in automotive suspensions, industrial

Strut springs, often overlooked but crucial components in various applications, play a vital role in supporting loads and providing stability. These resilient elements are commonly found in automotive suspensions, industrial machinery, and even everyday appliances. Understanding the mechanics of strut spring compression is essential for ensuring optimal performance, safety, and longevity in these systems.

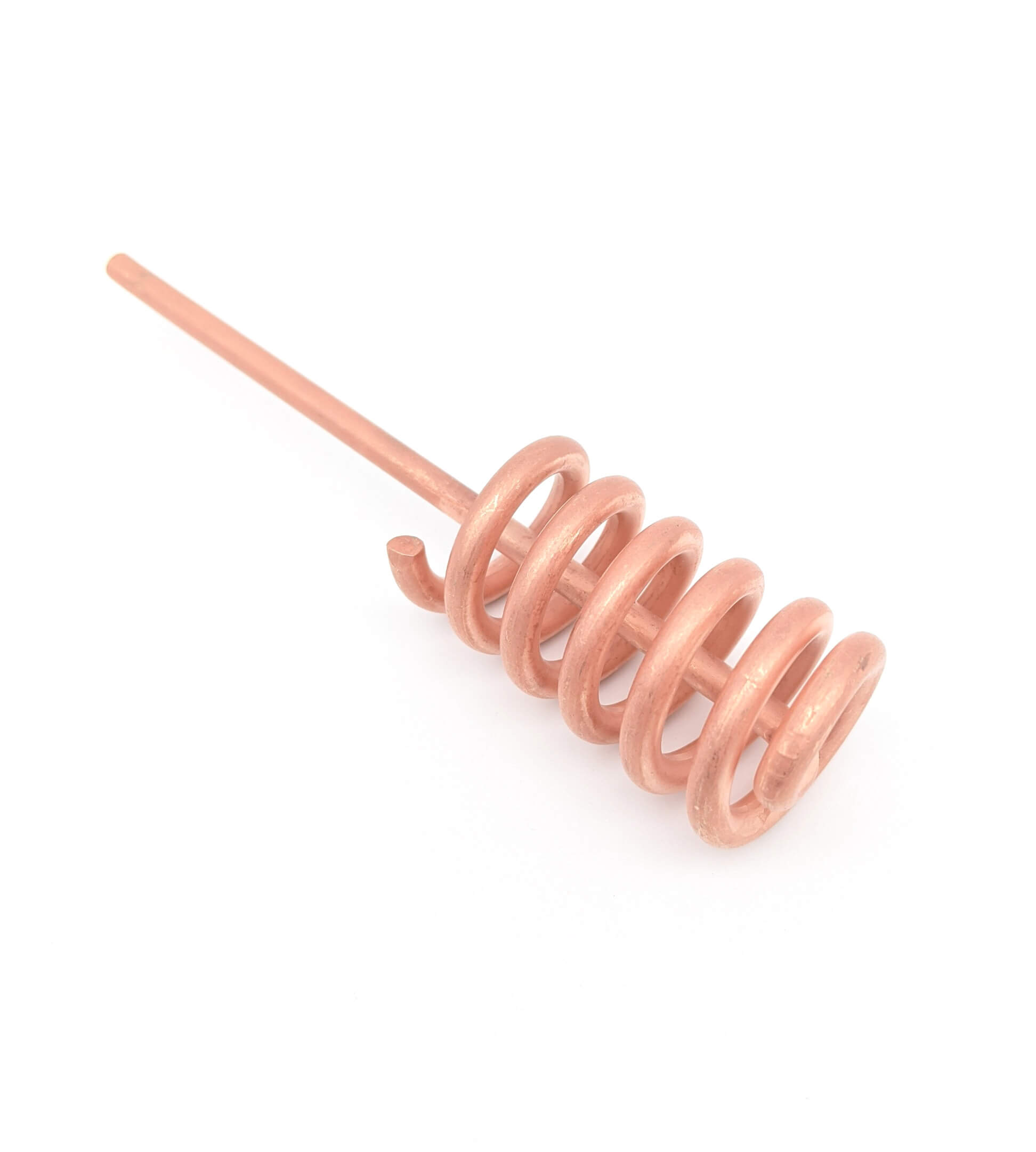

Strut springs are a type of helical spring, often crafted from high-strength steel, designed to withstand significant compression forces. Unlike traditional coil springs, strut springs are typically thicker and more robust, capable of handling heavier loads and more demanding environments. Their construction often involves multiple coils tightly wound together, contributing to their impressive strength and resilience.

The compression of a strut spring is its primary function. When a force is applied to the spring, it compresses, storing potential energy. This stored energy is then released as the spring returns to its original shape, providing a spring-loaded action. The compression of a strut spring is governed by the principle of Hooke's Law, which states that the force applied to the spring is proportional to the amount of deformation it experiences.

Strut spring compression is a critical factor in several key areas:

Several factors influence the compression behavior of a strut spring:

Strut spring compression finds application in a wide range of industries and everyday products:

Strut spring compression is a fundamental principle that drives the functionality of countless mechanical systems. Understanding the factors influencing strut spring compression is essential for engineers, designers, and anyone working with these vital components. From automotive suspensions to industrial machinery and everyday appliances, strut springs play a critical role in ensuring optimal performance, safety, and reliability.

Strut spring compression is a testament to the ingenuity and innovation that drives engineering solutions. These seemingly simple components are essential in a wide range of applications, showcasing their ability to handle heavy loads, absorb shocks, and provide stability in demanding environments. As technology continues to evolve, strut springs will undoubtedly continue to play a vital role in shaping the future of mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.