Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

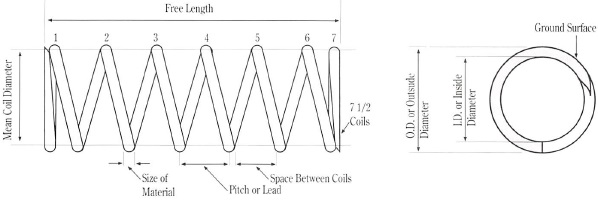

Strut springs, also known as coil springs, are essential components in various mechanical systems, playing a crucial role in providing support, absorbing shock, and controlling movement. Strut spring compression is

Strut springs, also known as coil springs, are essential components in various mechanical systems, playing a crucial role in providing support, absorbing shock, and controlling movement. Strut spring compression is a critical factor in determining the spring's performance and longevity. This article will delve into the fundamental principles of strut spring compression, exploring its significance in different applications and how it affects the overall system's functionality.

Strut spring compression refers to the amount of force required to compress the spring to a certain distance. This force is directly proportional to the spring's stiffness, measured in pounds per inch (lbs/in) or kilograms per millimeter (kg/mm). The stiffer the spring, the greater the force required to compress it. Compression is essential for strut springs to perform their intended functions, such as absorbing shocks, supporting loads, and maintaining a desired distance between components.

Imagine a car's suspension system. When a wheel encounters a bump, the strut spring compresses, absorbing the impact and preventing the shock from transferring to the vehicle's occupants. The amount of compression determines the ride quality and handling characteristics. A spring that compresses too much might make the ride feel soft and bouncy, while a spring that doesn't compress enough could result in a harsh and uncomfortable ride. Similarly, in other applications, such as machinery, compression ensures the proper functioning and stability of the system.

Several factors influence strut spring compression, including:

Strut spring compression plays a vital role in various applications, including:

Maintaining the correct strut spring compression is crucial for optimal performance and longevity. Over-compression can lead to spring fatigue, premature failure, and decreased load capacity. On the other hand, under-compression can result in a lack of support, excessive bounce, and instability. Regular inspection and replacement of worn-out springs are essential for ensuring proper operation.

The correct compression value is typically determined by the manufacturer's specifications and the specific application requirements. Engineers and technicians use specialized tools and techniques to measure and adjust spring compression to ensure it meets the desired specifications.

Strut spring compression is a fundamental concept that plays a significant role in various applications. Understanding its principles and factors affecting it is essential for optimizing system performance, ensuring safety, and extending product lifespan. Whether it's in automotive suspensions, industrial equipment, or consumer products, strut springs provide support, absorb shocks, and control movement, making them indispensable components in many mechanical systems.

By carefully considering strut spring compression, engineers and designers can achieve optimal functionality and reliability in various applications. Regular maintenance and proper selection of springs with appropriate compression characteristics are crucial for ensuring the long-term performance and safety of systems utilizing strut springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.