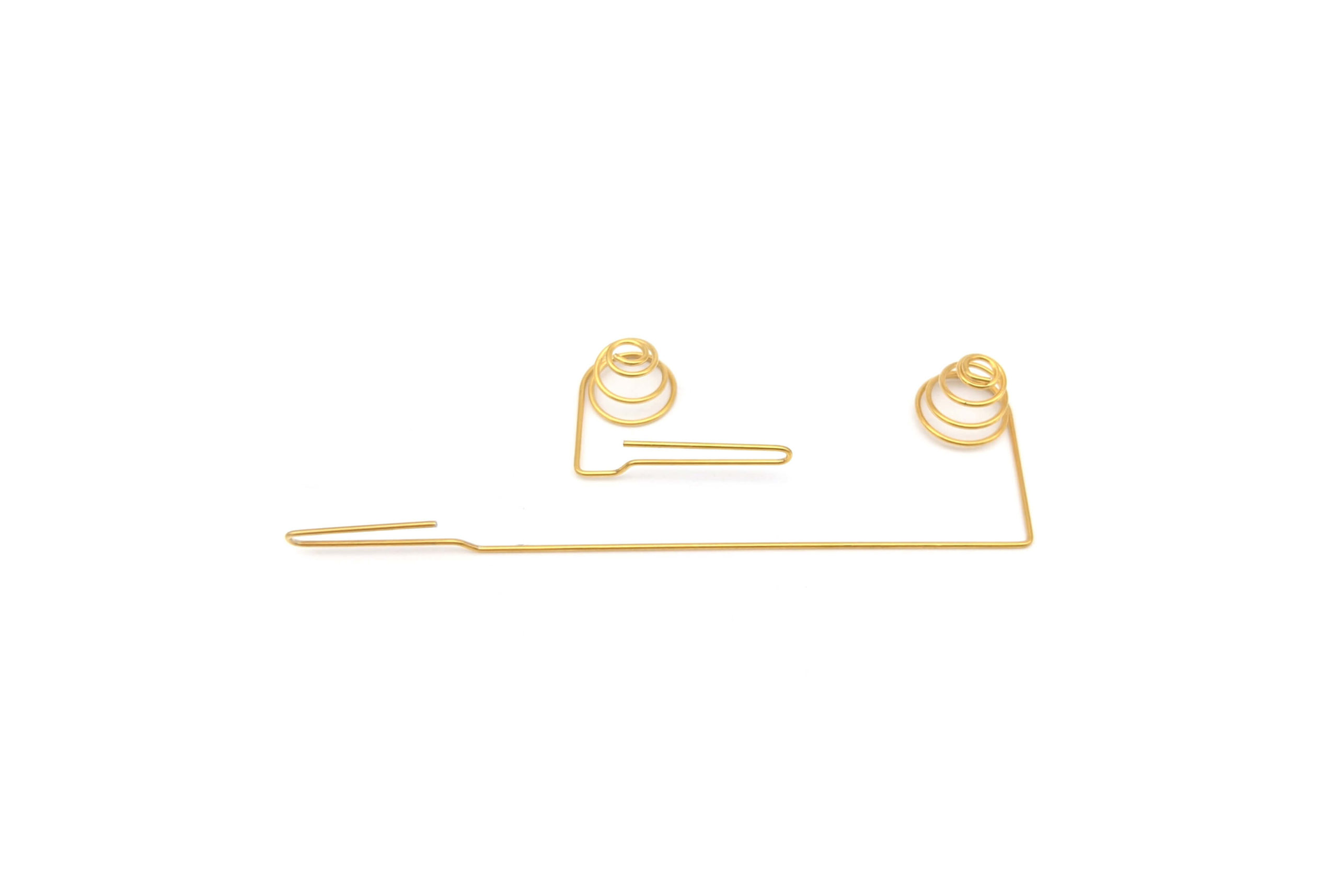

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless steel tension springs are a crucial component in a wide range of applications, offering exceptional durability and resistance to corrosion. They're designed to elongate under load, providing a reliable

Stainless steel tension springs are a crucial component in a wide range of applications, offering exceptional durability and resistance to corrosion. They're designed to elongate under load, providing a reliable and consistent force. This guide delves into the world of stainless steel tension springs, exploring their characteristics, applications, and how to choose the perfect spring for your needs.

Stainless steel tension springs, as their name suggests, are made from stainless steel, a metal alloy renowned for its strength, corrosion resistance, and durability. They are designed to stretch or elongate when a load is applied, storing energy within their structure. The spring then returns to its original length when the load is released. Unlike compression springs that shorten when loaded, tension springs are designed to extend under force. This inherent ability to stretch under tension makes them ideal for various applications where pulling or stretching forces are necessary.

Stainless steel tension springs offer a unique combination of advantages, making them the go-to choice for many applications:

Stainless steel tension springs find their way into countless applications across various industries, thanks to their remarkable properties. Here are some examples:

Selecting the appropriate stainless steel tension spring for your needs involves considering several factors:

For specialized applications where standard springs won't do, custom-made stainless steel tension springs offer a tailored solution. These springs can be designed to meet specific requirements for length, diameter, spring rate, and other critical parameters. Working with a reputable spring manufacturer allows you to get a spring that perfectly matches your application.

When selecting stainless steel tension springs, always choose reputable manufacturers and suppliers known for their commitment to quality and consistency. A well-made spring will perform reliably over time, ensuring the success of your application. Insist on springs manufactured according to industry standards and backed by quality control processes to ensure the springs meet your specific needs.

Stainless steel tension springs are indispensable in a wide range of industries and applications. Their inherent strength, corrosion resistance, and versatility make them the ideal choice for various purposes. By carefully considering the factors discussed in this guide, you can select the right stainless steel tension spring to meet your specific requirements and ensure the reliable operation of your systems.

Remember, choosing the right stainless steel tension spring is crucial for optimal performance and long-term reliability. Consult with experts and manufacturers to ensure you select the perfect spring for your application, ensuring smooth operation and a long service life.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.