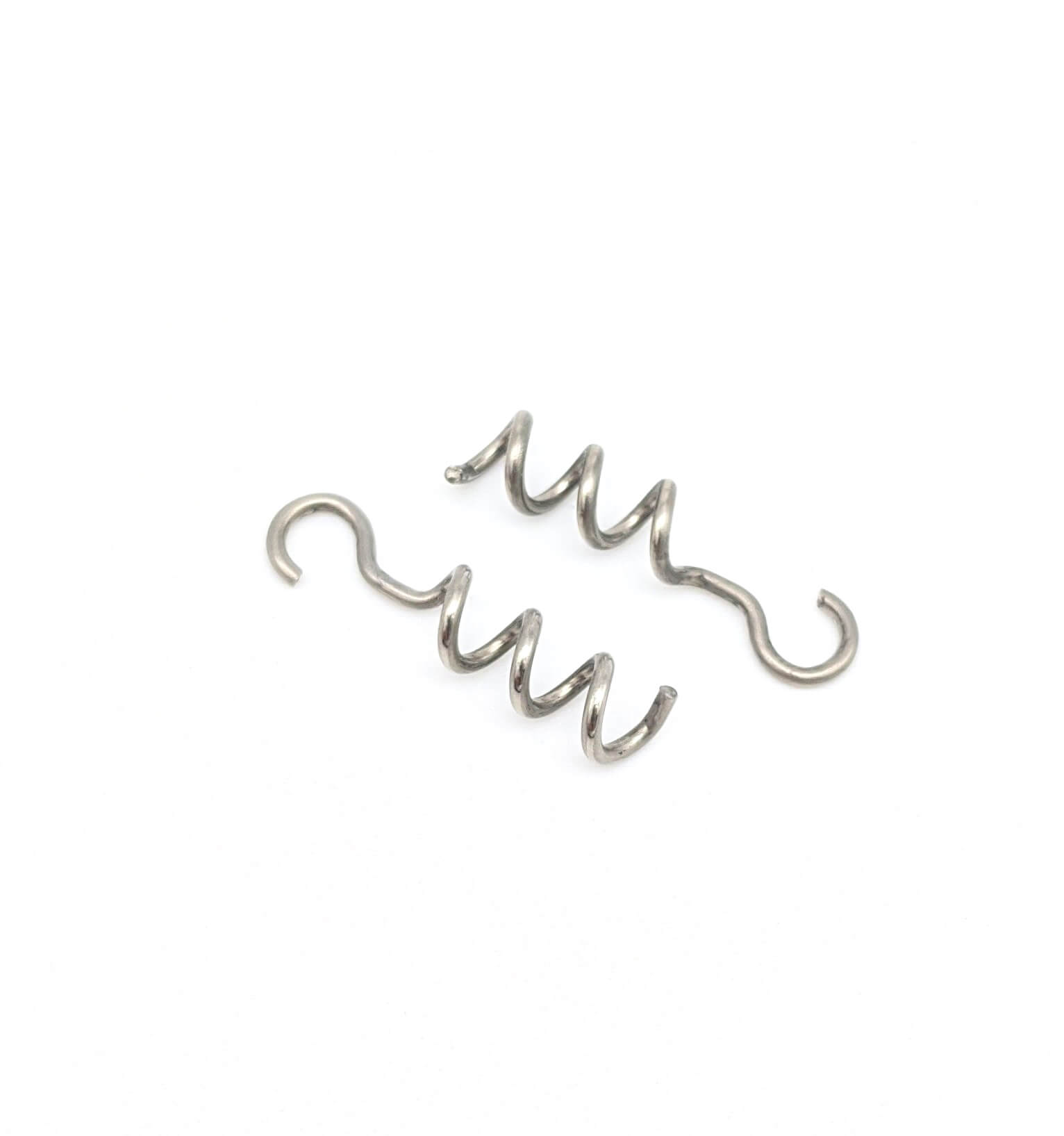

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless steel compression springs are ubiquitous in modern machinery and equipment, silently working behind the scenes to provide essential functions. These resilient components, often overlooked yet critical, are essential for

Stainless steel compression springs are ubiquitous in modern machinery and equipment, silently working behind the scenes to provide essential functions. These resilient components, often overlooked yet critical, are essential for absorbing shock, storing energy, and providing a restoring force in countless applications. Their durability, resistance to corrosion, and reliable performance make them a popular choice in diverse industries, from automotive and aerospace to medical and consumer products. Let's delve into the intricacies of stainless steel compression springs, exploring their characteristics, applications, and the factors that make them an indispensable part of our technological world.

Imagine a small, coiled piece of metal, seemingly insignificant, yet capable of exerting tremendous force. That's the essence of a compression spring, a device designed to store energy when compressed and release it when allowed to expand. Stainless steel, renowned for its strength and corrosion resistance, is a perfect material for these springs, ensuring their longevity and reliability in demanding environments.

Stainless steel, an alloy of iron, chromium, and often other elements, possesses a unique combination of properties that make it ideal for compression springs:

Stainless steel compression springs are the unsung heroes of countless applications. Here are a few examples showcasing their versatility:

Selecting the right stainless steel compression spring is crucial for optimal performance and longevity. Several factors need to be considered:

While the traditional helical compression spring design is widely used, engineers are constantly innovating to meet specific application demands. Here are some examples of advanced designs:

As technology advances, stainless steel compression springs will continue to evolve. Innovations in materials science and manufacturing processes will lead to even stronger, more resilient, and more efficient springs. Furthermore, the development of novel spring designs will further expand their applications, ensuring they remain integral to the world's technological progress.

Stainless steel compression springs are the silent workhorses of the mechanical world, providing essential functions in a wide range of applications. Their inherent strength, corrosion resistance, and reliability make them indispensable components in modern machinery and equipment. Understanding the characteristics and considerations involved in choosing these springs is crucial for engineers and designers, ensuring the optimal performance and longevity of their systems. As technology evolves, stainless steel compression springs will continue to adapt and innovate, further cementing their place as an essential part of our technological world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.