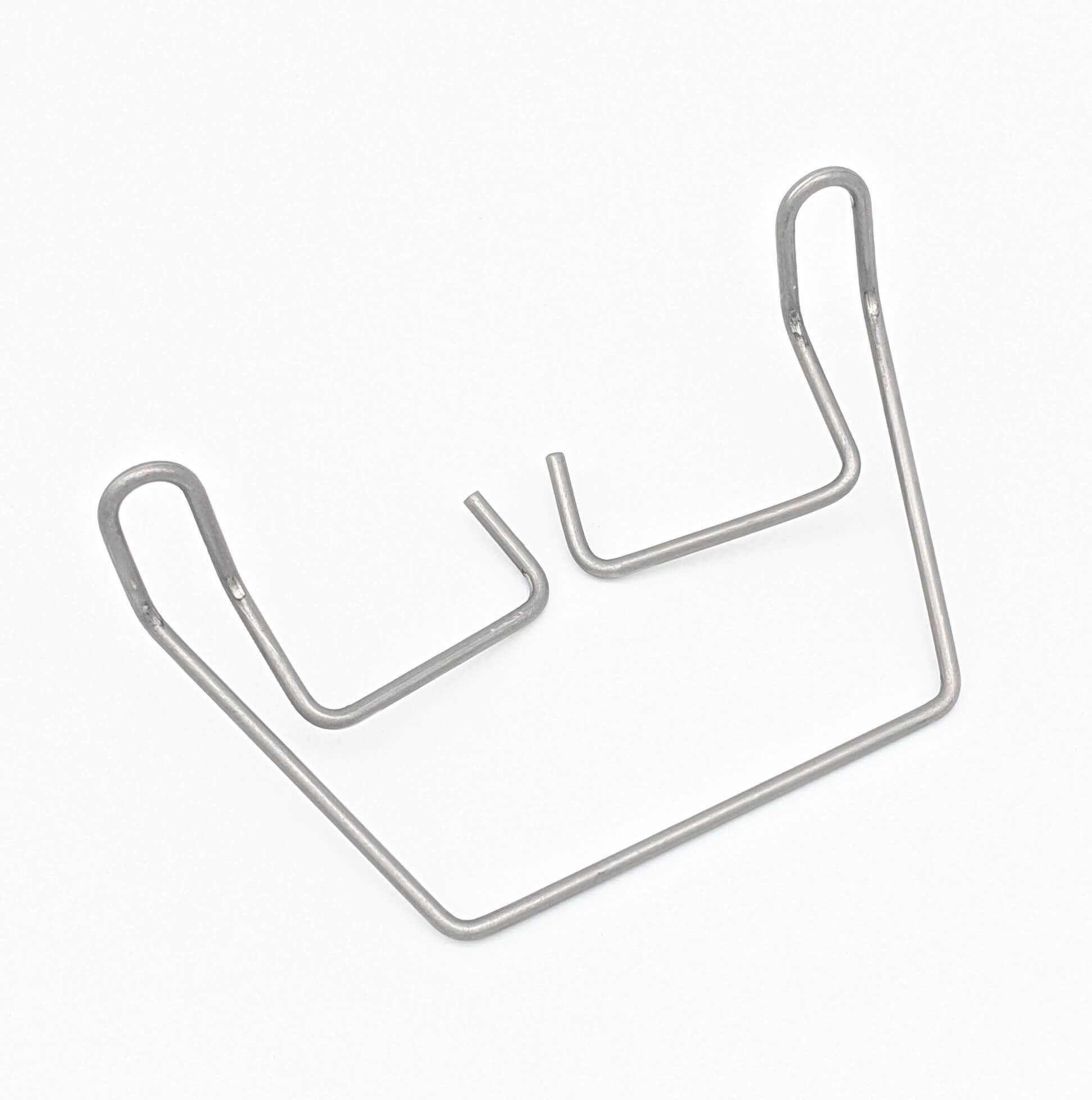

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless steel compression springs are ubiquitous, silently working behind the scenes to ensure the smooth operation of countless devices and systems. From the delicate mechanisms of watches to the heavy-duty

Stainless steel compression springs are ubiquitous, silently working behind the scenes to ensure the smooth operation of countless devices and systems. From the delicate mechanisms of watches to the heavy-duty suspension systems of vehicles, these resilient coils are the backbone of modern engineering. But despite their widespread use, many people remain unaware of the intricate design and manufacturing processes that go into these seemingly simple components. This article delves into the fascinating world of stainless steel compression springs, exploring their unique characteristics, applications, and the critical role they play in our daily lives.

Stainless steel compression springs are a type of mechanical spring designed to resist compression forces. They are typically made from high-quality stainless steel, known for its exceptional strength, corrosion resistance, and durability. These qualities make stainless steel compression springs ideal for a wide range of applications, from delicate medical devices to heavy-duty industrial machinery.

When a compression spring is compressed, it stores potential energy, much like a stretched rubber band. This stored energy is then released when the force is removed, causing the spring to return to its original shape. The amount of force required to compress a spring is determined by its spring rate, which is a measure of its stiffness. A higher spring rate indicates a stiffer spring, requiring more force to compress.

Stainless steel compression springs are used in an incredibly diverse array of applications, touching virtually every aspect of modern life. Here are just a few examples:

• **Automotive Industry:** Compression springs are essential components of vehicle suspension systems, helping to absorb shock and provide a smooth ride. They are also used in engine valve systems, clutches, and brakes.

• **Aerospace Industry:** Stainless steel compression springs are used in aircraft landing gear, control systems, and other critical components, where their reliability and resistance to extreme conditions are paramount.

• **Medical Devices:** Compression springs are used in medical instruments, such as surgical clamps, forceps, and retractors. They are also found in medical devices like nebulizers and insulin pumps.

• **Consumer Electronics:** These springs are used in countless electronic devices, including smartphones, laptops, and televisions. They provide pressure for buttons, hinges, and other mechanisms.

• **Industrial Machinery:** Stainless steel compression springs are used in heavy-duty equipment, such as construction machinery, manufacturing equipment, and power generation systems. They are often used for shock absorption, load support, and precise movement control.

• **Home Appliances:** Compression springs are essential components of washing machines, dryers, refrigerators, and other appliances, ensuring their smooth operation and durability.

The manufacturing of stainless steel compression springs is a complex and precise process that involves several key steps:

• **Wire Selection:** The process begins with selecting the appropriate stainless steel wire based on the required spring rate, load capacity, and operating environment.

• **Wire Forming:** The wire is then wound around a mandrel, creating a helical coil. The pitch, or spacing between the coils, is carefully controlled to achieve the desired spring rate.

• **Heat Treatment:** Heat treatment is often applied to the spring to enhance its strength and durability. This process involves heating the spring to a specific temperature and then cooling it down at a controlled rate.

• **Finishing:** Finally, the spring is finished to meet the desired specifications. This may involve grinding, polishing, or other surface treatments to improve its appearance and performance.

Stainless steel compression springs offer a unique combination of features that make them ideal for a wide range of applications:

• **High Strength:** Stainless steel is known for its exceptional strength, enabling compression springs to withstand high loads without deformation.

• **Corrosion Resistance:** Stainless steel exhibits excellent resistance to corrosion, making it suitable for use in harsh environments, such as marine applications and industrial settings.

• **Durability:** Stainless steel compression springs are highly durable, capable of withstanding repeated compression and extension cycles without fatigue.

• **Flexibility:** These springs can be designed with varying degrees of flexibility, allowing them to be used in applications requiring different levels of spring rate.

• **Customizable Design:** Compression springs can be custom-designed to meet specific requirements in terms of size, shape, spring rate, and load capacity.

Stainless steel compression springs are the unsung heroes of modern engineering, quietly ensuring the smooth operation of countless devices and systems. Their resilience, durability, and versatility make them indispensable components in a vast array of industries. From the delicate mechanisms of watches to the heavy-duty suspension systems of vehicles, these springs play a vital role in our daily lives, often without us even realizing it. Their ability to store and release energy with precision and reliability makes them essential for a wide range of applications, highlighting their profound impact on our world.

As technology continues to advance, stainless steel compression springs are likely to play an even greater role in our future. Their exceptional properties and versatility make them ideal for use in emerging technologies, such as robotics, aerospace, and renewable energy. Whether we are aware of it or not, these resilient coils are integral to the smooth functioning of the modern world, silently working behind the scenes to make our lives easier and more efficient.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.