Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

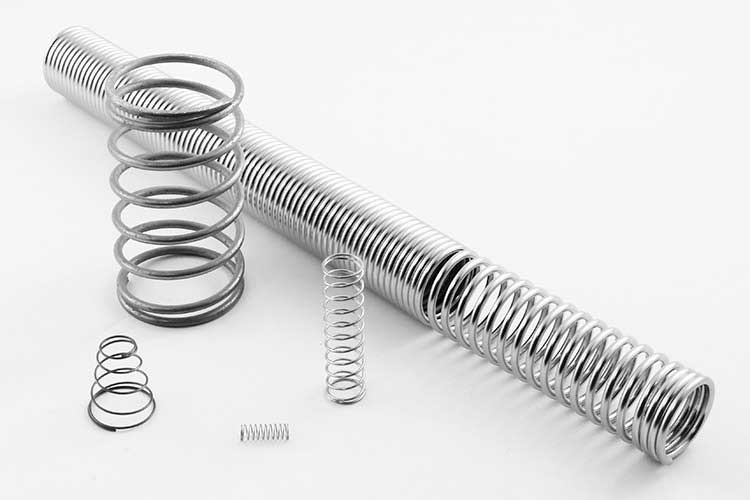

Stainless steel compression springs are ubiquitous in countless applications, quietly working behind the scenes to provide support, stability, and controlled movement. From the intricate mechanisms of medical devices to the

Stainless steel compression springs are ubiquitous in countless applications, quietly working behind the scenes to provide support, stability, and controlled movement. From the intricate mechanisms of medical devices to the robust machinery of industrial equipment, these seemingly simple coils play a crucial role in ensuring smooth and reliable operation. Their resilience, durability, and versatility make them indispensable across various industries, and understanding their properties and applications is key to optimizing performance and achieving desired outcomes.

Stainless steel compression springs are favored for their exceptional properties, making them ideal for a wide range of demanding applications. Here are some of the key advantages that make them stand out:

**Corrosion Resistance:** Stainless steel's inherent resistance to rust and corrosion is paramount in environments where moisture, chemicals, or harsh conditions are present. Whether it's a medical device operating in a sterile setting or an industrial component exposed to the elements, stainless steel springs maintain their integrity over time, ensuring reliable performance.

**Strength and Durability:** Stainless steel compression springs possess impressive strength and durability, allowing them to withstand significant forces and repeated cycles of compression and release. Their resilience ensures consistent performance even under heavy loads, making them suitable for high-stress applications. Moreover, stainless steel's resistance to fatigue means that these springs can endure extended use without experiencing premature wear or breakage, ensuring a long service life.

**Versatility:** Stainless steel compression springs come in a wide variety of sizes, shapes, and configurations, catering to the specific requirements of diverse applications. This versatility allows engineers and designers to select the perfect spring to meet the unique needs of their projects, whether it's a miniature spring for a delicate instrument or a large spring for heavy-duty machinery.

Stainless steel compression springs are employed in a vast array of industries, demonstrating their versatility and indispensable nature.

**Medical Devices:** The healthcare industry relies heavily on stainless steel compression springs due to their biocompatibility, corrosion resistance, and ability to withstand sterilization processes. They are found in medical devices such as syringes, surgical instruments, and prosthetic limbs, ensuring precise and safe operation.

**Automotive Industry:** From engine components to suspension systems, stainless steel compression springs are essential in the automotive industry. Their strength, durability, and resistance to fatigue ensure reliable performance under demanding conditions, contributing to the safety and longevity of vehicles.

**Aerospace and Defense:** In applications where weight, strength, and durability are critical, stainless steel compression springs excel. They are found in aircraft, spacecraft, and military equipment, ensuring stability and performance under extreme conditions.

**Consumer Products:** Stainless steel compression springs are also commonplace in consumer products. From the retractable pens we use daily to the springs in our household appliances, these springs ensure smooth operation and longevity. Their presence in everyday items underscores their pervasive nature.

Selecting the appropriate stainless steel compression spring for a given application is crucial to ensure optimal performance and longevity. Several factors must be considered when making this choice:

**Spring Rate:** The spring rate, often referred to as the spring constant, represents the force required to compress the spring by a specific distance. Understanding the desired spring rate is essential for achieving the desired level of support and resistance.

**Material Grade:** Different grades of stainless steel possess varying levels of strength, corrosion resistance, and other properties. Choosing the appropriate material grade is critical for meeting the specific requirements of the application.

**Wire Diameter and Coil Diameter:** The wire diameter and coil diameter influence the spring's overall strength, flexibility, and travel. Determining the optimal dimensions for the specific application is crucial for achieving the desired performance.

**End Configuration:** The end configuration of the spring determines how it is attached to other components. Various end types exist, including closed, open, and ground ends, each offering distinct advantages for specific applications.

Stainless steel compression springs are ubiquitous components that silently contribute to the smooth operation of countless devices and systems. Their exceptional properties, including corrosion resistance, strength, durability, and versatility, make them indispensable across various industries. From the intricate mechanisms of medical devices to the robust machinery of industrial equipment, these seemingly simple coils play a crucial role in ensuring reliable performance. Understanding their properties and applications is key to optimizing performance and achieving desired outcomes.

As we continue to advance technologically, the demand for reliable and durable components like stainless steel compression springs will only grow. Their ability to withstand demanding conditions, provide precise support, and ensure smooth operation makes them essential in shaping our world. Whether it's a medical device restoring health or a spacecraft exploring the cosmos, these seemingly simple coils play a vital role in driving innovation and improving our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.