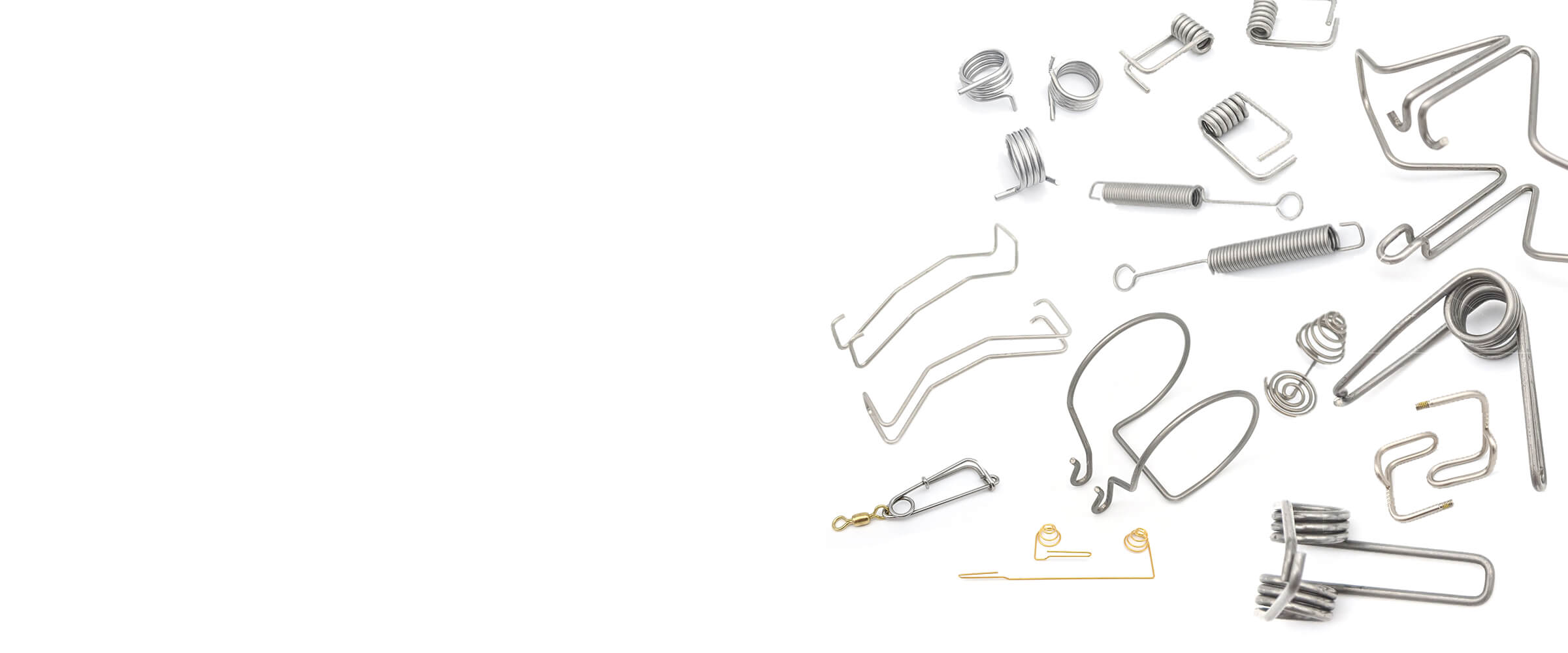

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without springs. Cars wouldn't bounce, doors wouldn't close smoothly, and even our everyday gadgets would be drastically different. Among the various types of springs, stainless compression springs

Imagine a world without springs. Cars wouldn't bounce, doors wouldn't close smoothly, and even our everyday gadgets would be drastically different. Among the various types of springs, stainless compression springs stand out as silent workhorses, their resilience and durability making them indispensable across diverse industries. This article delves into the fascinating world of stainless compression springs, exploring their unique properties, applications, and why they're the backbone of countless modern marvels.

Stainless steel, renowned for its corrosion resistance and strength, is the perfect material for springs that face demanding conditions. These springs, when compressed, store potential energy, releasing it when needed. Their inherent ability to withstand wear and tear, even in harsh environments, makes them ideal for applications where reliability is paramount.

But why are stainless compression springs so widely used? Well, their unique properties offer numerous advantages:

Corrosion Resistance: Stainless steel forms a protective oxide layer that resists rust and corrosion. This is especially beneficial in industries like food processing, pharmaceuticals, and marine engineering, where exposure to moisture, chemicals, or salt can compromise other metal springs.

High Strength-to-Weight Ratio: Stainless compression springs are surprisingly strong considering their lightweight nature. This makes them suitable for applications where minimizing weight is crucial, such as aerospace components, medical devices, and automotive parts.

Excellent Fatigue Resistance: Repeated compression and release cycles can wear down springs, but stainless compression springs excel in resisting fatigue, ensuring they retain their function over long periods. Think of them as the tireless athletes of the spring world.

Diverse Designs: Manufacturers can customize stainless compression springs to meet specific load requirements and design constraints. From intricate micro-springs used in precision instruments to hefty springs found in industrial machinery, the design flexibility is truly remarkable.

Stainless compression springs are ubiquitous, contributing to the smooth operation of countless devices and systems. Here are some key industries where they find their niche:

Automotive Industry: You'll find them in suspension systems, clutches, engine valves, and even seat adjustments, ensuring a comfortable and reliable ride. They handle the constant jostling and vibrations that come with the territory.

Aerospace and Aviation: Stainless compression springs play a vital role in aircraft and spacecraft components. Their ability to withstand extreme temperatures, pressure, and vibrations makes them ideal for landing gear, control mechanisms, and safety systems.

Medical Devices: Stainless compression springs find their way into medical equipment like surgical instruments, prosthetic limbs, and drug delivery devices. Their biocompatibility and corrosion resistance ensure safety and long-term performance.

Electronics and Appliances: From the delicate springs in your smartphone to the robust ones in your washing machine, stainless compression springs are everywhere in the world of electronics and appliances. They ensure smooth operation and prevent unwanted wear and tear.

Industrial Machinery: In heavy-duty machinery, stainless compression springs are indispensable for handling powerful forces. They power hydraulic systems, operate lifting mechanisms, and contribute to the reliability of various industrial processes.

Selecting the appropriate stainless compression spring involves considering several factors:

Load Requirements: The spring must be strong enough to handle the intended load, whether it's a gentle push or a forceful compression.

Space Constraints: The spring needs to fit within the available space, taking into account its compressed and extended dimensions.

Environmental Considerations: Factors like temperature, humidity, and exposure to chemicals influence the choice of stainless steel grade and spring design.

Cost and Availability: Finding a balance between the desired performance and budget is essential, considering that specialty springs might be more expensive.

As technology advances, stainless compression springs are likely to become even more sophisticated. With innovations in materials science, we can expect even more durable, lightweight, and efficient springs. Advancements in manufacturing techniques will enable the creation of intricate designs, expanding their applications even further.

In conclusion, stainless compression springs are silent heroes of modern engineering, their resilience, strength, and versatility making them indispensable across diverse fields. Whether you're driving a car, using a smartphone, or undergoing a medical procedure, chances are stainless compression springs are working diligently behind the scenes, ensuring smooth operation and lasting performance. Their humble yet crucial role in shaping the world around us deserves recognition.

The next time you encounter a spring, take a moment to appreciate its silent strength. Stainless compression springs may not be flashy, but they are the unsung heroes of countless devices and systems, making modern life possible and improving our everyday experiences. Their enduring contribution to innovation and progress is a testament to their remarkable engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.