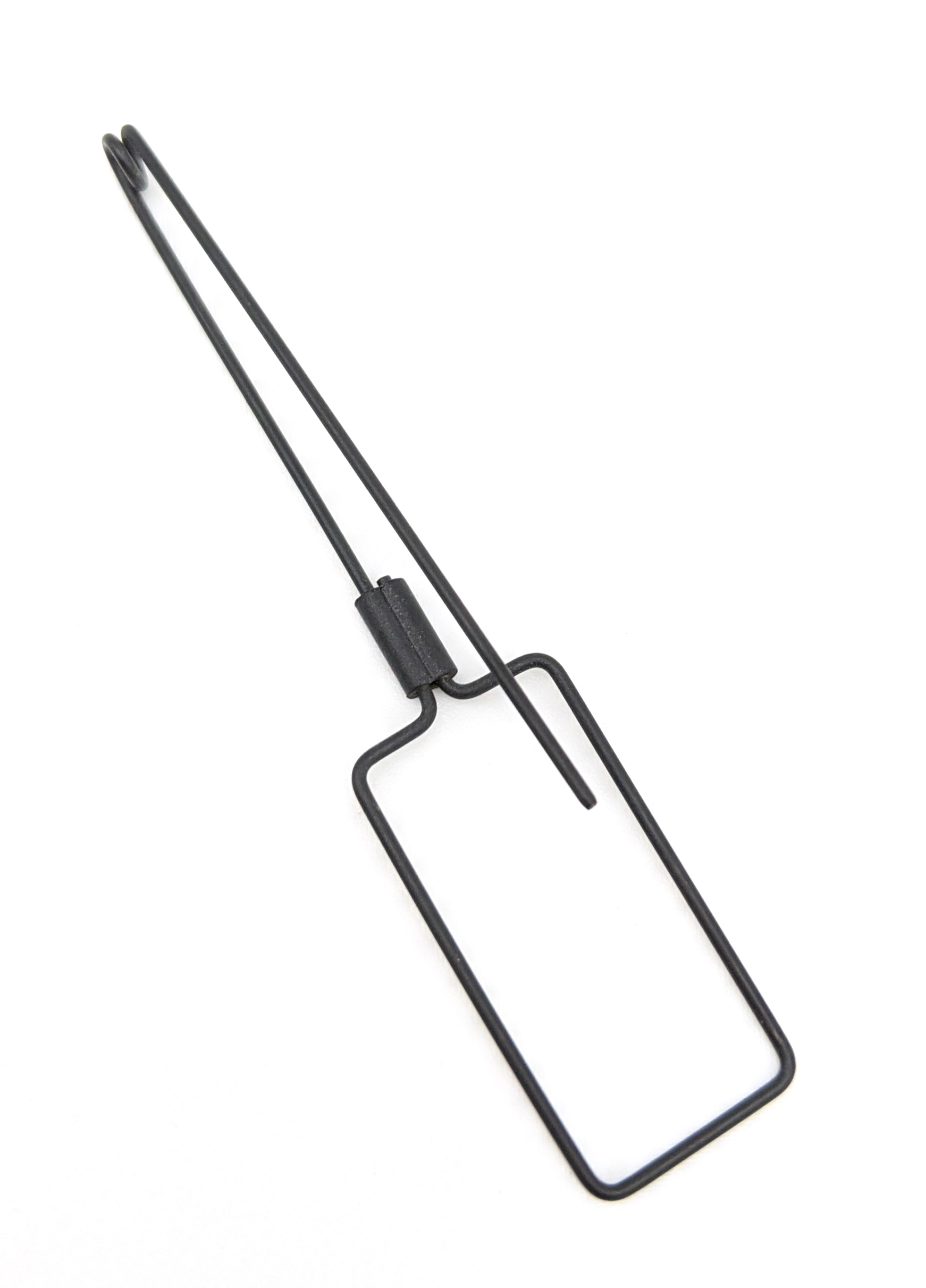

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless compression springs are a vital component in a wide range of applications, from automotive and aerospace to medical devices and consumer products. Their resilience, corrosion resistance, and ability to

Stainless compression springs are a vital component in a wide range of applications, from automotive and aerospace to medical devices and consumer products. Their resilience, corrosion resistance, and ability to withstand high temperatures make them ideal for demanding environments. This comprehensive guide will delve into the world of stainless compression springs, exploring their properties, types, applications, and factors to consider when choosing the right spring for your needs.

Stainless compression springs, as the name suggests, are helical springs made from stainless steel. These springs are designed to store and release mechanical energy when compressed. They are characterized by their ability to withstand significant force and deformation while maintaining their shape and functionality.

Stainless compression springs offer numerous advantages over other spring materials, making them a preferred choice for many applications. Here are some key benefits:

Corrosion Resistance: Stainless steel is renowned for its exceptional resistance to corrosion, even in harsh environments. This property is crucial in applications where exposure to moisture, chemicals, or extreme temperatures is a concern. Think about a spring used in a saltwater environment, or a spring within a medical device that comes into contact with bodily fluids. Stainless steel springs will hold up remarkably well, preventing rust and maintaining their integrity.

High Strength: Stainless steel exhibits high tensile strength, allowing stainless compression springs to withstand significant loads without permanent deformation. This strength makes them suitable for applications that require robust and reliable springs.

High Fatigue Resistance: Stainless compression springs can withstand repeated compression and release cycles without failing. This is essential for applications that involve dynamic loads and vibrations, ensuring the spring continues to perform consistently over time.

Temperature Stability: Stainless steel springs can withstand a wide range of temperatures, both high and low, without losing their spring properties. This characteristic is essential for applications where thermal fluctuations are expected.

Flexibility: Stainless compression springs can be manufactured in various configurations, with different wire diameters, spring indices, and end types. This flexibility allows engineers to choose the most suitable spring for their specific application requirements.

Stainless compression springs are available in various types, each with unique characteristics and applications. Some common types include:

AISI 302 Stainless Steel: This type of stainless steel is widely used for compression springs due to its good balance of strength, corrosion resistance, and workability. It's often a standard choice when a general-purpose stainless spring is needed.

AISI 304 Stainless Steel: This type offers excellent corrosion resistance, making it ideal for applications where exposure to harsh environments is a concern. It's a popular choice for applications involving chemicals, food processing, or marine environments.

AISI 316 Stainless Steel: This type offers superior corrosion resistance to both AISI 302 and 304, particularly against chloride ions. This makes it suitable for applications involving saltwater, chemical processing, and medical implants.

AISI 410 Stainless Steel: This type offers high strength and hardness, making it ideal for applications that demand high load-bearing capacity. It's often used in automotive and aerospace applications.

Stainless compression springs are used in a vast array of applications, across various industries. Here are some examples:

Automotive Industry: Suspension systems, clutch mechanisms, and engine valve springs.

Aerospace Industry: Landing gear, control systems, and aircraft components.

Medical Devices: Surgical instruments, implants, and medical equipment.

Consumer Products: Pens, electronic devices, and toys.

Industrial Equipment: Pumps, compressors, and machinery.

Choosing the right stainless compression spring for your application depends on several factors, including:

Spring Rate: The spring rate defines how much force is required to compress the spring by a specific distance. This is a critical factor in determining the spring's performance and suitability for your application.

Spring Length: The overall length of the spring is essential for fitting it into your design and ensuring proper functionality.

Spring Diameter: The diameter of the spring coil determines its load-bearing capacity and overall size.

Wire Diameter: The thickness of the spring wire determines its strength and durability. A thicker wire results in a stronger and more durable spring.

End Type: The end configuration of the spring affects its functionality and attachment methods. Common end types include closed and open loops.

Working Environment: The operating environment, including temperature, humidity, and chemical exposure, should be considered when choosing the appropriate stainless steel grade.

Stainless compression springs are invaluable components in numerous applications, providing resilience, corrosion resistance, and high performance. By understanding their properties, types, and application factors, you can select the ideal stainless compression spring for your specific needs, ensuring optimal functionality and longevity in your designs.

In conclusion, choosing the right stainless compression spring is crucial for achieving optimal performance and reliability in your applications. By carefully considering the factors discussed above, you can confidently select the perfect stainless compression spring that will meet your specific requirements and ensure the success of your design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.