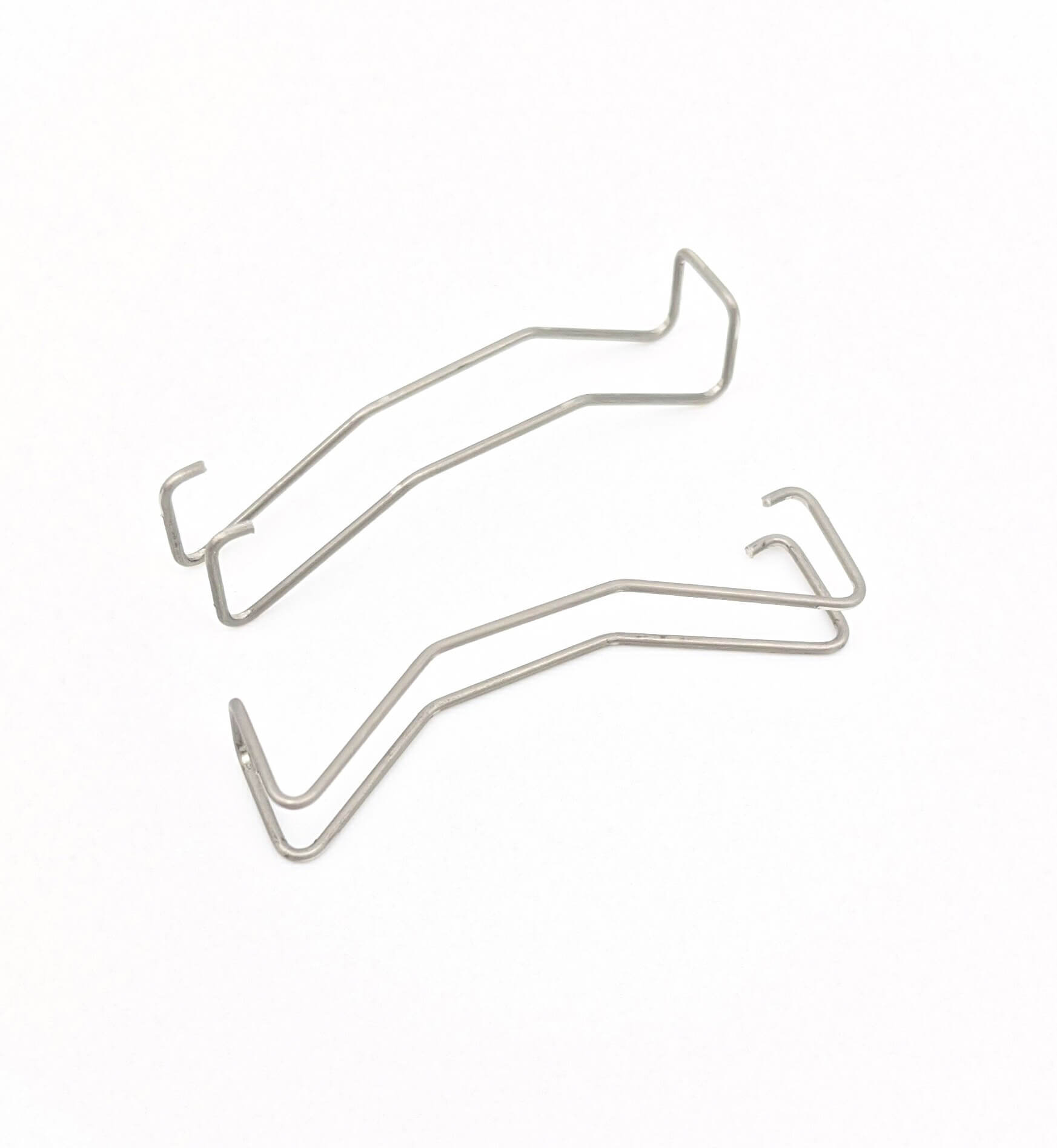

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless compression springs, known for their durability and resistance to corrosion, are essential components in countless applications. From aerospace to medical devices, these springs play a vital role in providing

Stainless compression springs, known for their durability and resistance to corrosion, are essential components in countless applications. From aerospace to medical devices, these springs play a vital role in providing reliable force and motion control. This comprehensive guide delves into the intricacies of stainless compression springs, exploring their characteristics, types, manufacturing processes, applications, and considerations for choosing the right spring for your needs.

Stainless compression springs are helical coils crafted from stainless steel, designed to absorb and store energy when compressed. They are prized for their exceptional resistance to corrosion, making them ideal for environments where moisture, chemicals, or harsh conditions are present. The inherent strength and resilience of stainless steel allow these springs to withstand significant loads and perform reliably over extended periods.

The world of stainless compression springs is diverse, offering various types to suit specific application requirements. Let's explore some key classifications:

The choice of stainless steel grade directly influences a spring's properties, such as its strength, corrosion resistance, and temperature tolerance. Common stainless steel grades for compression springs include:

The configuration of the spring ends plays a crucial role in determining how the spring interacts with its surroundings. Common end types include:

The thickness of the spring wire is a critical factor affecting its load-carrying capacity and flexibility. A larger wire diameter generally results in a stronger and stiffer spring. Conversely, a smaller diameter leads to a more flexible spring with lower load capacity.

The spring index is the ratio of the mean coil diameter to the wire diameter. A higher spring index indicates a more flexible spring, while a lower index results in a stiffer spring. The spring index significantly influences the spring's performance and load characteristics.

Stainless compression springs are typically manufactured using cold-forming techniques, ensuring dimensional accuracy and superior material properties. The process involves:

Stainless compression springs find wide-ranging applications across various industries due to their exceptional properties:

Selecting the appropriate stainless compression spring for your application requires careful consideration of various factors:

Stainless compression springs are versatile and reliable components essential for countless applications. Understanding their characteristics, types, manufacturing processes, and applications empowers you to make informed decisions and choose the perfect spring for your needs. By considering load requirements, operating environment, and durability, you can ensure the long-term performance and success of your products and systems.

As you embark on your spring selection journey, remember that consulting with a reputable spring manufacturer is highly recommended. They possess the expertise to guide you through the intricate details of spring design, materials, and manufacturing processes, ensuring that you find the ideal stainless compression spring for your application.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.