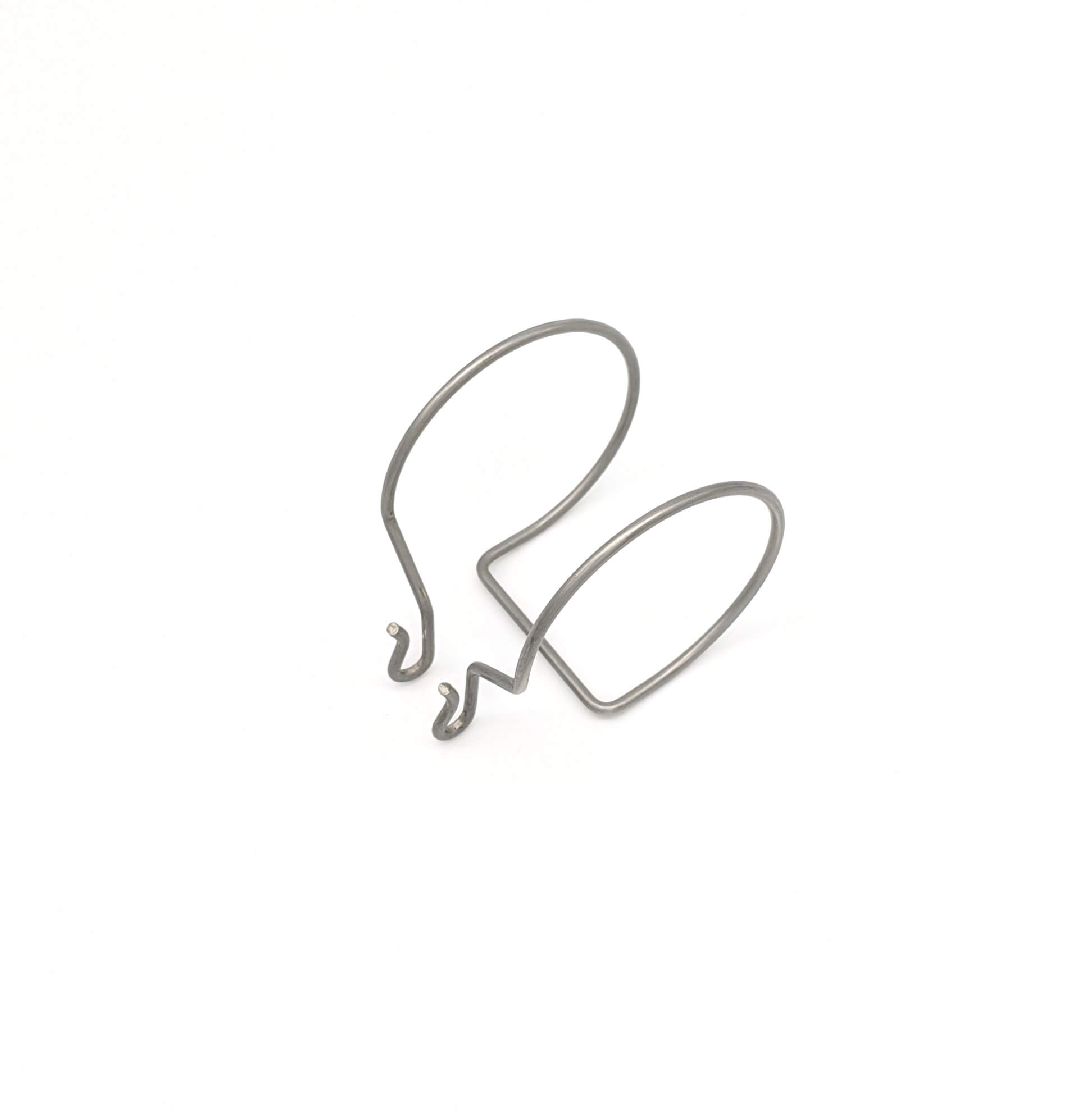

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of precision engineering, where every component plays a crucial role in the smooth functioning of a system, disc springs, also known as Belleville washers, often go unnoticed.

In the realm of precision engineering, where every component plays a crucial role in the smooth functioning of a system, disc springs, also known as Belleville washers, often go unnoticed. These seemingly simple components are anything but ordinary. They possess unique characteristics that make them invaluable for a wide range of applications, from delicate medical devices to heavy-duty industrial machinery. This article delves into the world of stackd wav disc springs, exploring their design, function, advantages, and the critical role they play in ensuring optimal performance and reliability.

Stackd wav disc springs, as the name suggests, are a special type of disc spring that's made by stacking multiple wavy disc springs together. They are essentially a collection of conical washers that are carefully shaped and stacked to create a spring effect. This unique configuration allows for a significant increase in the spring rate, making them ideal for applications where high forces and compact designs are essential.

At their core, stackd wav disc springs consist of individual discs that are typically made from hardened steel or other high-strength materials. These discs feature a distinct wave-like profile, which is what gives them their unique properties. This wave-like shape allows the spring to store energy efficiently and release it consistently under load.

The use of stackd wav disc springs brings a host of benefits to the table, making them a popular choice across various industries. Let's delve into some of their key advantages:

One of the most prominent advantages of stackd wav disc springs is their remarkable ability to handle high loads. The stacking of multiple discs creates a cumulative effect, enabling them to withstand forces that would overwhelm conventional springs. This makes them perfect for applications where heavy-duty performance is non-negotiable.

In a world where space is often a constraint, stackd wav disc springs shine brightly. Their compact design allows them to be incorporated into tight spaces, making them ideal for applications where minimizing footprint is a priority. This feature is particularly beneficial in electronics, aerospace, and other industries where size matters.

Stackd wav disc springs offer precise force control due to their predictable load-deflection characteristics. This predictability is crucial for applications where consistent and reliable force application is paramount. This feature is particularly important in medical devices, automotive components, and other industries where safety and performance are paramount.

The high-strength materials used in stackd wav disc springs, coupled with their robust design, ensures exceptional durability. They can withstand repeated cycles of compression and release, making them reliable components for long-term use. This resilience is invaluable in applications where wear and tear are unavoidable, such as heavy machinery and industrial equipment.

The versatility of stackd wav disc springs is evident in their wide range of applications. Here are some prominent examples:

The precision force control and compact design of stackd wav disc springs make them ideal for use in medical devices. They are used in medical instruments, surgical equipment, and prosthetics, ensuring reliable and safe operation.

The automotive industry heavily relies on stackd wav disc springs for a variety of applications. They are used in clutch plates, shock absorbers, and suspension systems, providing reliable force control and vibration dampening.

The aerospace industry demands high-performance components that can withstand extreme conditions. Stackd wav disc springs are used in aerospace applications like landing gear, actuators, and other critical components where reliability is paramount.

Stackd wav disc springs are used in various heavy-duty industrial applications, including presses, pumps, and other machinery, where their ability to handle high loads and withstand harsh environments is crucial.

In the world of electronics, stackd wav disc springs play a vital role in connectors, switches, and other components, ensuring reliable contact and electrical conductivity. Their compact size and ability to handle high pressures make them ideal for these applications.

The demand for stackd wav disc springs continues to grow as engineers seek solutions for increasingly demanding applications. The advent of advanced materials and manufacturing techniques further enhances their capabilities, making them even more versatile and reliable. The future of stackd wav disc springs is bright, with their applications likely to expand into new and innovative areas of engineering.

Stackd wav disc springs are a testament to the ingenuity of engineering. Their compact design, high load capacity, and exceptional durability make them invaluable components in various industries. As technology continues to advance, we can expect to see even more innovative applications of these seemingly simple but incredibly powerful springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.