Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous coiled metal wonders, are often taken for granted. They silently perform their duties in countless applications, from the gentle compression of a car's suspension to the powerful

Springs, those ubiquitous coiled metal wonders, are often taken for granted. They silently perform their duties in countless applications, from the gentle compression of a car's suspension to the powerful tension of a watch's mainspring. But behind their seemingly simple design lies a world of complex engineering principles. This article delves into the fascinating realm of springs, exploring the intricacies of their design, the types of springs commonly used, and their pivotal role in various industries.

Springs are essentially elastic elements designed to store and release mechanical energy. Their fundamental function is to resist deformation under applied force and return to their original shape when the force is removed. This ability to store and release energy is what makes springs indispensable in various applications.

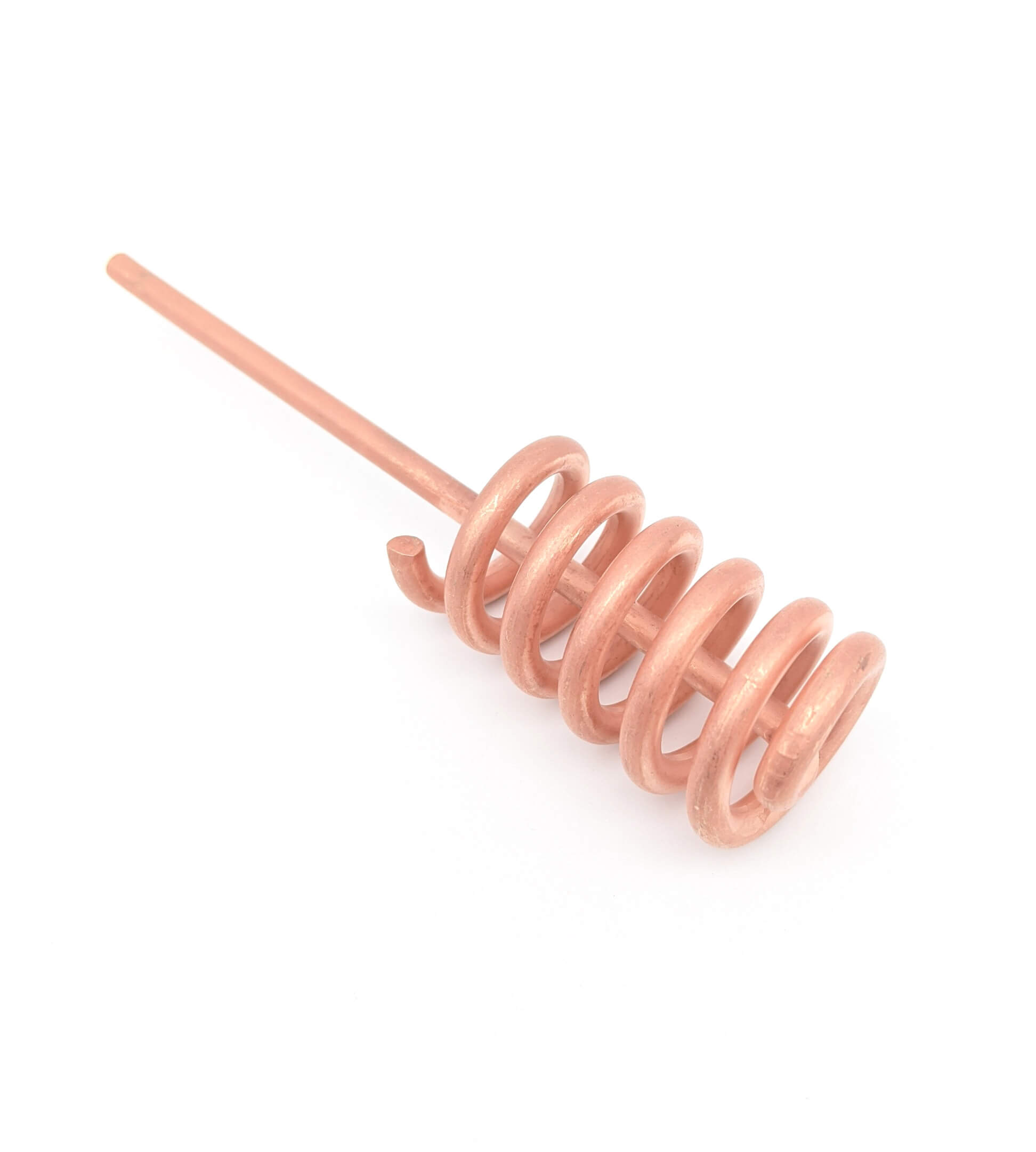

The most common type of spring is the **coil spring**, which comprises a helical coil of wire. These springs come in various shapes and sizes, each designed for specific purposes. For instance, compression springs, as their name suggests, are designed to resist compressive forces, while tension springs are designed to resist tensile forces. Torsion springs, on the other hand, are designed to resist twisting forces.

Springs come in a variety of types, each with its unique characteristics and applications:

The choice of material for a spring is crucial to its performance. The material must possess high elasticity, durability, and resistance to fatigue. Some commonly used materials for springs include:

Springs are essential components in a wide range of industries and applications:

Designing and manufacturing springs is a complex process that requires meticulous attention to detail. The design of a spring depends on its specific application, the forces it needs to withstand, and the material used. Several factors are considered during spring design, including:

Spring manufacturing involves several steps, including wire forming, heat treatment, and surface finishing. The manufacturing process must be carefully controlled to ensure that the spring meets the required specifications. Spring manufacturers use various specialized equipment to form the wire into the desired shape and ensure consistent quality.

Spring technology is constantly evolving to meet the demands of modern industries. Advancements in materials science and manufacturing processes are leading to the development of new and improved spring designs. For instance, composite materials are being used to create springs that are lighter and stronger than traditional metal springs. Nanotechnology is also playing a role in the development of springs with improved properties, such as increased fatigue resistance and enhanced corrosion resistance.

Springs, though often overlooked, play a vital role in countless applications. Their ability to store and release mechanical energy makes them indispensable in various industries, from automotive and aerospace to medical and consumer products. Understanding the principles of spring design, the types of springs available, and the materials used in their manufacture is essential for engineers and anyone interested in the fascinating world of mechanical engineering. As spring technology continues to evolve, we can expect to see even more innovative applications for these versatile components in the future.

Springs, those humble yet powerful components, are a testament to the ingenuity of engineering. Their ability to store and release energy with precision and reliability makes them essential for countless applications. As technology advances, we can expect springs to continue playing a vital role in shaping the world around us, silently but effectively performing their critical functions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.