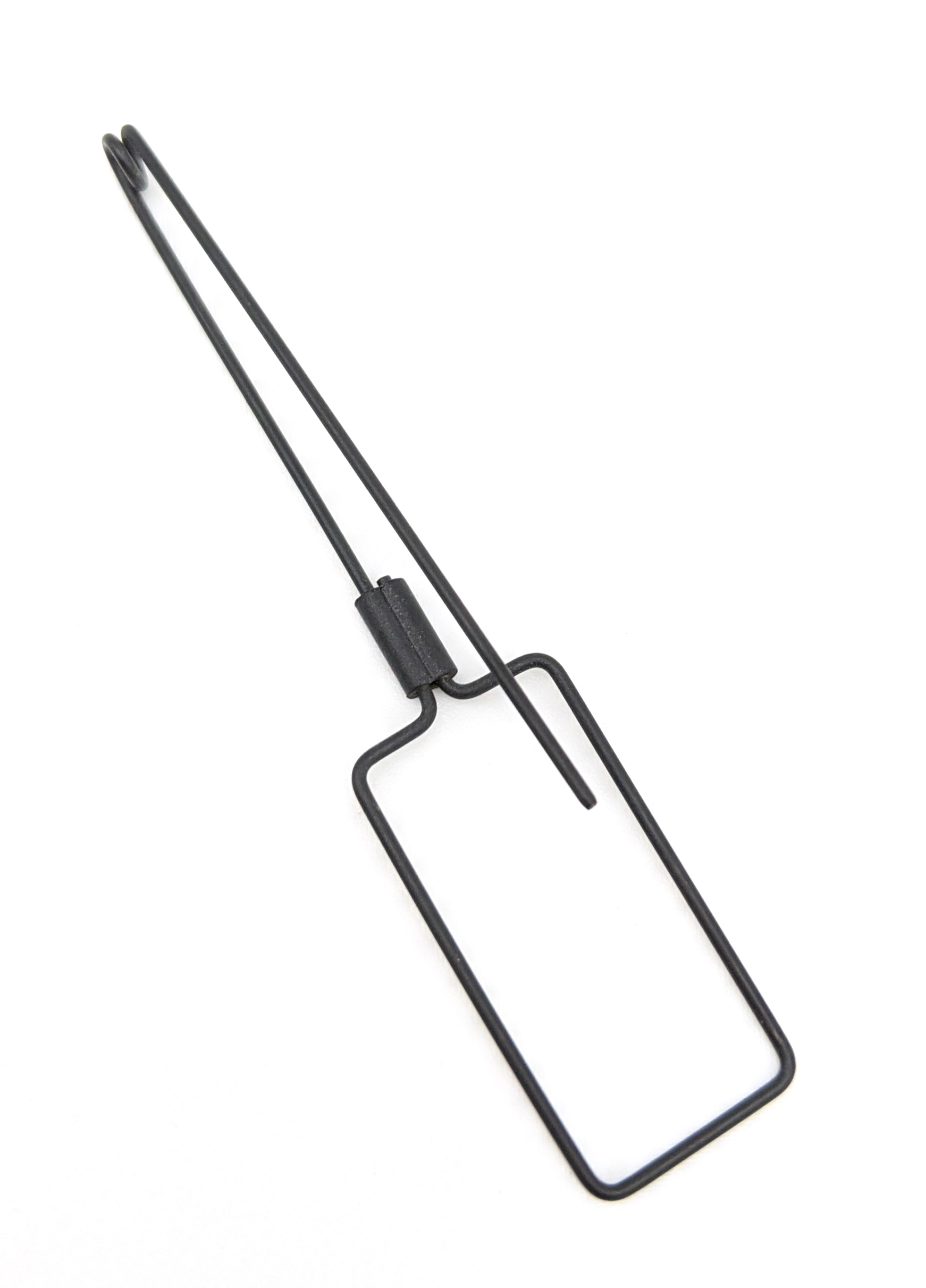

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring washers, those small, often overlooked components, play a critical role in ensuring the secure fastening of numerous applications. While they might seem like insignificant metal discs, they are the

Spring washers, those small, often overlooked components, play a critical role in ensuring the secure fastening of numerous applications. While they might seem like insignificant metal discs, they are the unsung heroes behind countless reliable connections. This article will delve into the world of spring washers, exploring their history, various types, applications, and how they contribute to the durability and longevity of countless products.

Spring washers, also known as Belleville washers, are fascinating components that combine simplicity with remarkable functionality. These washer-shaped elements are designed to create a constant tension force on the fastener, preventing it from loosening over time due to vibration, shock, or thermal expansion. Imagine a bolt and nut connection exposed to the constant jostling of a car's engine or the fluctuating temperatures of a piece of machinery. Without a spring washer, the connection could gradually loosen, potentially leading to disastrous consequences. Spring washers act as a dynamic safeguard, ensuring the fastener stays put and maintains its integrity.

Their remarkable ability to provide constant tension stems from their unique shape. Spring washers are typically made of hardened steel and have a conical or dished form. This shape allows them to deflect under pressure, storing mechanical energy. As the fastener is tightened, the spring washer is compressed, storing this energy. When subjected to external forces, the spring washer will resist this force, working tirelessly to keep the connection secure. This constant force exerted by the spring washer is what makes it such an effective solution for preventing loosening.

While the modern iteration of the spring washer might seem recent, its origins can be traced back centuries. Early versions, often made of simple metal discs with a slight curvature, were used in various mechanical applications. The invention of the Belleville washer, named after Julien Belleville who patented the design in the late 19th century, revolutionized the industry. His innovative design significantly improved the spring washer's load-carrying capacity and provided a more reliable solution for preventing loosening.

Spring washers come in various shapes and sizes, each designed to tackle specific applications. Here are some of the most common types:

Standard Belleville Washers: The classic Belleville washer, with its distinctive conical shape, is widely used in numerous applications. It offers a high spring rate and can withstand significant loads.

Conical Washers: Similar to standard Belleville washers, conical washers have a conical shape, but they are usually smaller and thinner. They are often used in smaller applications where space is limited.

Wave Washers: These washers have a wave-like pattern, providing a higher load capacity than traditional Belleville washers. They are commonly used in applications where high shock and vibration resistance is crucial.

Serrated Washers: Featuring serrated edges, these washers enhance the grip on the fastener, preventing it from loosening even under extreme conditions. They are frequently used in applications involving high torque and dynamic loads.

Stacked Washers: By stacking multiple washers together, you can adjust the spring rate and load capacity. This flexibility allows engineers to fine-tune the spring washer's performance for specific applications.

Spring washers are ubiquitous in countless industries and applications, from automotive and aerospace to electronics and construction. Here are some notable examples:

Automotive: In vehicles, spring washers play a vital role in securing suspension components, engine parts, and brake systems. They ensure these critical components remain tightly fastened, even during rigorous driving conditions.

Aerospace: The high-stress and high-vibration environment of aerospace applications demands robust fastenings. Spring washers contribute significantly to the safety and reliability of aircraft and spacecraft.

Electronics: Spring washers are used in various electronic devices, including circuit boards, connectors, and enclosures. They help ensure the secure connection of sensitive components, preventing failures and ensuring reliable operation.

Construction: In the construction industry, spring washers are employed to secure structural elements, such as steel beams and columns. Their ability to maintain constant tension is vital in ensuring the integrity and stability of structures.

Selecting the right spring washer for your application is crucial for achieving optimal performance and longevity. Several factors must be considered:

Load Capacity: The spring washer must be able to withstand the applied load without failing. This factor determines the type and size of the spring washer required.

Spring Rate: The spring rate determines the amount of force required to deflect the spring washer. This is often a crucial factor in controlling the preload on the fastener and ensuring proper performance.

Material: The material of the spring washer is crucial for its durability and corrosion resistance. Steel is a common material, but other materials, such as stainless steel or bronze, may be necessary in specific environments.

Spring washers, though often overlooked, are essential components that ensure the secure fastening of countless products. Their simple yet ingenious design provides constant tension, preventing loosening and guaranteeing reliable performance. Understanding their importance, types, and applications can lead to better design choices, increased product durability, and greater overall system reliability.

Next time you encounter a spring washer, take a moment to appreciate its unassuming yet vital role. These small, often overlooked components contribute significantly to the safety, reliability, and longevity of countless applications. They are the unsung heroes of secure fastenings, quietly ensuring that our world keeps running smoothly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.