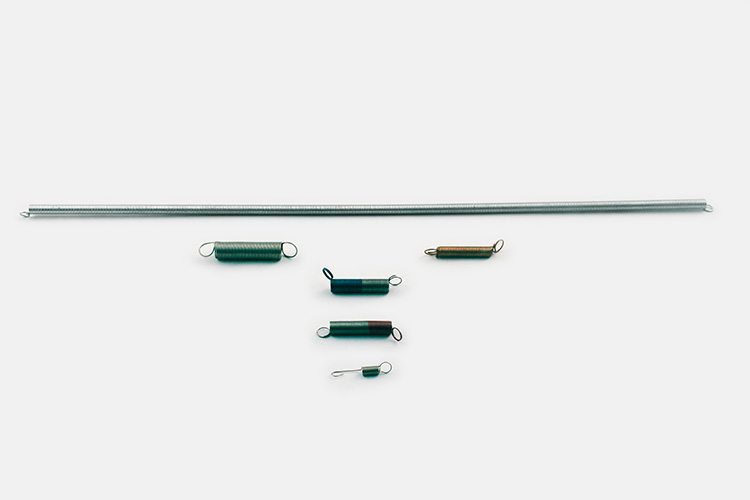

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered what those tiny, often overlooked, metal discs are that you see nestled beneath nuts and bolts? These are spring washers, and despite their seemingly insignificant size,

Have you ever wondered what those tiny, often overlooked, metal discs are that you see nestled beneath nuts and bolts? These are spring washers, and despite their seemingly insignificant size, they play a crucial role in the world of engineering and construction. They are much more than just a decorative element; they are the silent guardians ensuring a secure and lasting connection, often under the most demanding conditions. From everyday household items to industrial machinery, spring washers are instrumental in keeping things together, preventing loosening, and ensuring reliability. This article delves into the fascinating world of spring washers, exploring their purpose, types, applications, and the reasons why they are essential for robust and dependable fastening solutions.

Spring washers, sometimes called 'Belleville washers', are specialized fasteners designed to maintain a consistent clamping force between two surfaces, even under fluctuating conditions like vibration, temperature changes, or load shifts. They achieve this through their unique shape, often resembling a conical disc with a slight dome in the center. This distinctive form allows them to act as a miniature spring, providing constant tension on the fastener.

Think of a spring washer as a tiny elastic band. When a bolt is tightened, the washer compresses, storing potential energy. As the force on the bolt decreases due to vibration or loosening, the washer expands, pushing back against the bolt and maintaining the clamping force. This inherent spring-like action helps prevent loosening and ensures a secure connection.

Imagine a chair with loose screws. The instability can be annoying, leading to wobbly seats and an overall frustrating experience. In a more serious scenario, consider a critical machine component where loosening could lead to failure, potentially causing harm or disrupting operations. This is where spring washers come in. They provide a vital layer of security, ensuring that components remain firmly connected, even when subjected to stresses and strains.

The advantages of using spring washers are multifaceted:

The world of spring washers is not as simple as it might seem. There's a variety of types, each designed to address specific application requirements. Let's explore some common types:

These are the most common type, featuring a conical disc shape with a slight dome in the center. They are readily available and used in a wide range of applications.

As the name suggests, these are designed for applications demanding high clamping forces and resistance to extreme vibrations. They are often used in heavy machinery, construction equipment, and other high-stress environments.

These are compact springs with a wave-like configuration, offering high spring force in a small footprint. They are often used in applications where space is limited, such as in electronics and precision machinery.

These washers feature teeth on the outer diameter, which dig into the mating surface to create a strong lock. They are ideal for applications where loosening due to torque reversal is a concern.

Similar to external tooth washers, these have teeth on the inner diameter, engaging with the bolt head to provide secure locking. They are often used in applications where the mating surface is delicate or cannot be marred by external teeth.

Spring washers find their place in a wide variety of applications, playing an integral role in ensuring secure connections and reliable operation. Here are some common examples:

Selecting the appropriate spring washer is crucial for achieving a secure and long-lasting connection. Several factors must be considered when choosing a spring washer:

Spring washers are often unseen heroes in the world of fastening. Their ability to maintain a secure connection under a range of conditions is crucial in ensuring the reliability and safety of everything from household appliances to industrial machinery. By understanding the different types of spring washers and the factors to consider when selecting them, you can ensure a robust and dependable fastening solution for any project.

The next time you see a spring washer, remember that it is more than just a small metal disc. It is a testament to the ingenuity of engineers and a vital component in the world of secure fastening. So, appreciate the unsung heroes of secure connections – the humble, yet powerful, spring washers.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.