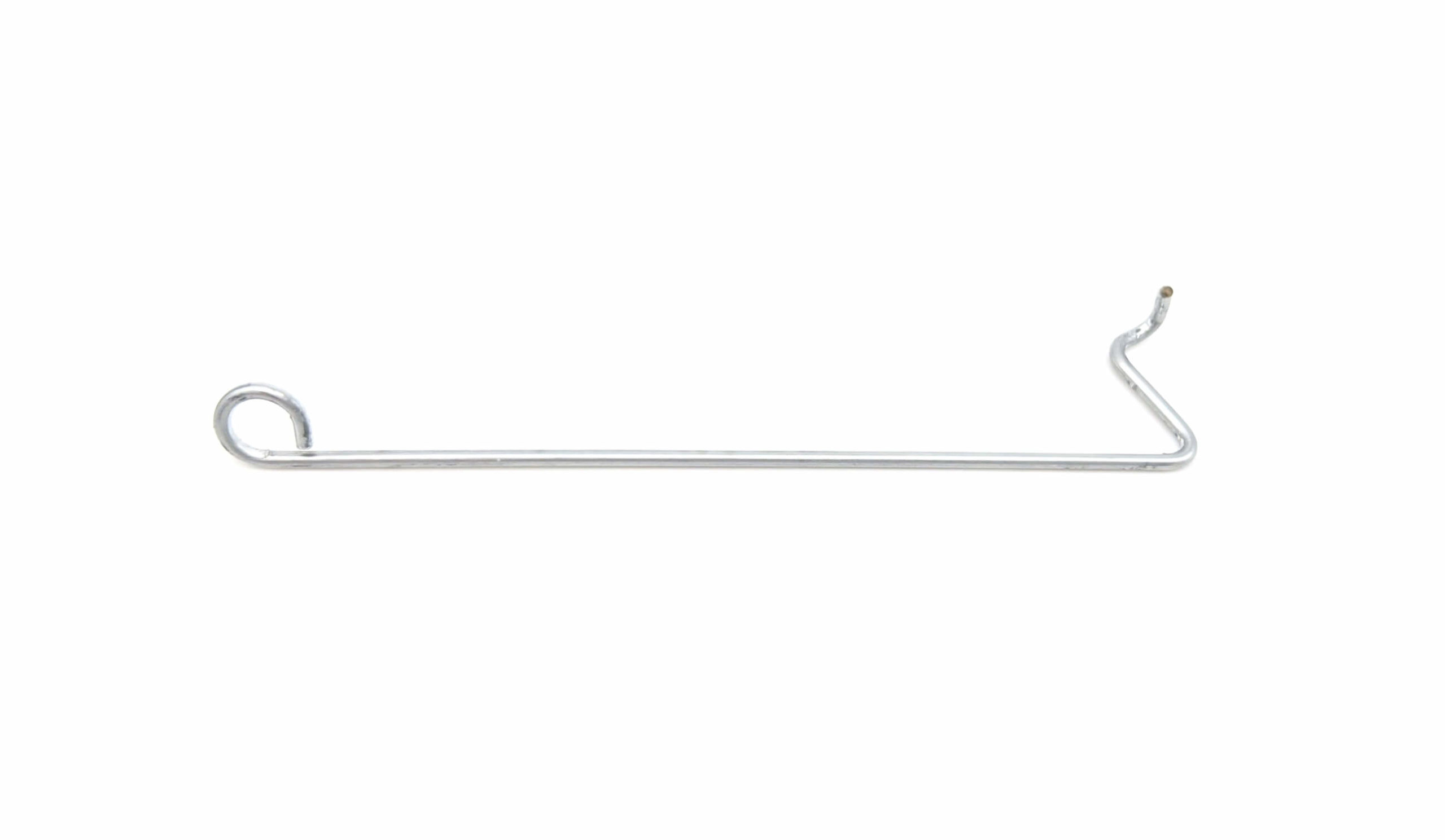

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring torsion, a fundamental concept in mechanical engineering, describes the twisting or rotation of a spring under applied force. This phenomenon plays a crucial role in various systems, from simple

Spring torsion, a fundamental concept in mechanical engineering, describes the twisting or rotation of a spring under applied force. This phenomenon plays a crucial role in various systems, from simple toys to complex machinery. Understanding spring torsion is essential for engineers designing and analyzing systems that rely on springs for their functionality.

Imagine twisting a rubber band. As you apply force, the band starts to coil and resists your twist. This resistance is what we call spring torsion. In engineering terms, spring torsion is the twisting moment or torque that a spring exerts when subjected to an angular displacement. This moment is directly proportional to the angle of twist, a relationship defined by the spring's torsional stiffness.

Torsional stiffness, often represented by the symbol 'kt', is a crucial property of a spring. It quantifies the spring's resistance to twisting. Higher torsional stiffness means the spring requires more force to twist it by a certain angle. This property is determined by the spring's material, geometry, and manufacturing process.

Torsion springs come in various shapes and sizes, each with unique applications. Some common types include:

Spring torsion finds applications in a wide variety of fields, including:

Several factors influence the torsional behavior of a spring. These include:

The torsional stiffness (kt) of a spring can be calculated using various formulas, depending on the specific spring type. For a coil spring, the formula is:

kt = (G * d4) / (8 * D * n)

Where:

Understanding spring torsion is essential for engineers designing and analyzing mechanical systems. When choosing a spring for a particular application, engineers need to consider the required torsional stiffness and the load the spring will be subjected to. Incorrectly selecting a spring can lead to premature failure or malfunction of the system.

Spring torsion is a fundamental concept in mechanics that plays a crucial role in various systems. Engineers must understand the principles of spring torsion to design and analyze systems that rely on springs for their functionality. By understanding the factors that influence spring torsion and the methods for calculating it, engineers can ensure optimal performance and longevity of their designs.

Spring torsion is a fascinating aspect of mechanical engineering that impacts our daily lives in countless ways. From the delicate workings of a watch to the robust performance of industrial machinery, torsion springs provide the power and precision necessary for a wide range of applications. Understanding this fundamental concept empowers engineers to design and innovate, pushing the boundaries of mechanical systems and shaping our world in unexpected ways.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.