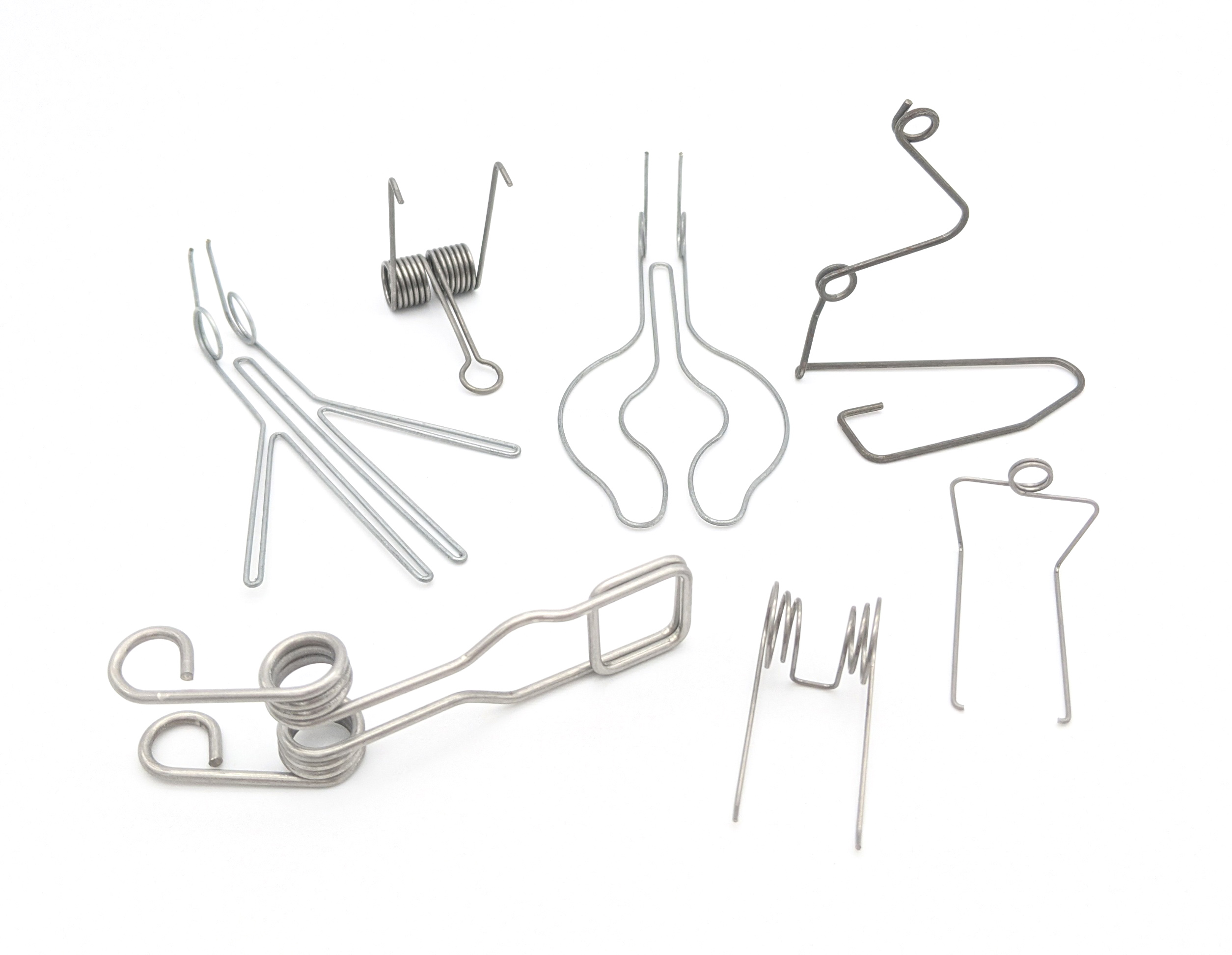

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring tension, a seemingly simple concept, plays a vital role in countless aspects of our lives. From the delicate mechanisms of a watch to the robust suspension systems of vehicles,

Spring tension, a seemingly simple concept, plays a vital role in countless aspects of our lives. From the delicate mechanisms of a watch to the robust suspension systems of vehicles, spring tension is the unseen force that makes these everyday objects work. It's a fundamental principle in physics, shaping the way things move, store energy, and even respond to our actions. This article delves into the fascinating world of spring tension, exploring its applications, properties, and the science behind it.

Imagine a simple coil spring. When you press down on it, you're applying compression force. This force causes the spring to compress, storing energy within its coils. When you release the pressure, the spring recoils, releasing that stored energy and pushing back against your hand. This interplay of compression, energy storage, and release is what we call spring tension.

The strength of the spring tension, or its stiffness, is determined by a crucial factor: the spring constant. This value tells us how much force is required to compress or extend the spring by a certain distance. A higher spring constant means the spring is stiffer and requires more force to deform. Conversely, a lower spring constant indicates a softer spring that deforms more easily.

Now, let's explore the key applications of spring tension:

Spring tension is a ubiquitous force in the world around us, impacting everything from the smallest of mechanisms to the largest of structures. Here are some prominent examples:

Think about the springy action of a ballpoint pen, the satisfying click of a lighter, or the responsive touch of a keyboard. These simple devices rely on spring tension to function. Spring tension also governs the workings of retractable pens, clothespins, and even the spring-loaded mechanisms in many toys.

The automotive industry relies heavily on spring tension. Vehicle suspension systems utilize coil springs and leaf springs to absorb shocks and vibrations from the road, ensuring a smooth ride. Additionally, spring tension plays a crucial role in the engine, powering valve movements and other critical components.

Spring tension plays a crucial role in aerospace and aviation. Aircraft landing gear often incorporates spring tension to cushion the impact of landing. Springs are also used in various actuators and control mechanisms, ensuring the precise operation of aircraft systems.

Springs are indispensable tools in manufacturing and engineering. They serve as actuators, providing controlled movement in various processes. They act as shock absorbers, protecting delicate components from harsh impacts. And they can be used as power sources, storing and releasing energy for various applications.

The science behind spring tension is rooted in Hooke's Law, a fundamental principle in physics. Hooke's Law states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you stretch or compress a spring, the greater the force it exerts back.

This relationship is often represented by the equation: F = -kx, where:

The negative sign indicates that the force exerted by the spring is in the opposite direction to the displacement. This means the spring always tries to restore itself to its original position.

While Hooke's Law provides a foundational understanding, spring tension involves several advanced concepts and variations:

In real-world scenarios, springs may not always obey Hooke's Law perfectly. Some springs exhibit non-linear behavior, meaning the force exerted is not directly proportional to displacement. This can occur due to factors like material properties, complex spring geometries, or exceeding the spring's elastic limit.

In many applications, springs are subjected to damping forces, such as friction or air resistance. These forces oppose the motion of the spring, gradually reducing its oscillations and energy storage. Damped springs are often used in situations where controlled movements and energy dissipation are critical.

Advanced spring designs allow for dynamic adjustments in stiffness. These springs can change their resistance to compression or extension, providing a range of behaviors depending on the application. This is achieved through various mechanisms, such as incorporating hydraulic or pneumatic systems within the spring design.

Spring tension is a fundamental force that shapes our world in countless ways. It enables the precise movements of delicate instruments, cushions the impact of heavy vehicles, and powers complex machinery. From the simple act of opening a door to the intricate operations of aircraft, spring tension plays a vital role in our modern world. It's a force that often goes unnoticed, yet its influence is pervasive, demonstrating the elegance and power of simple scientific principles in everyday life.

The next time you encounter a spring, take a moment to appreciate the hidden force at work. Spring tension, a simple concept with profound implications, demonstrates the ingenuity of human engineering and the elegance of the natural world. It's a reminder that even the smallest forces can have a significant impact on our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.