Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

When designing or repairing machinery, selecting the appropriate spring component is crucial. Spring spacers and coil springs are two commonly used options, each with unique characteristics and applications. Understanding their

When designing or repairing machinery, selecting the appropriate spring component is crucial. Spring spacers and coil springs are two commonly used options, each with unique characteristics and applications. Understanding their differences and how to choose the right one for your specific needs is key to ensuring optimal performance and longevity. This article will delve into the key features, applications, and considerations for choosing between spring spacers and coil springs.

Spring spacers, also known as spring washers, are small, disc-shaped components designed to provide axial load support and prevent loosening of fasteners. They are typically made of hardened steel and have a slightly conical or beveled shape. The unique design of spring spacers allows them to create a pre-load on the fastener, ensuring a secure connection and preventing movement under vibration or shock.

Spring spacers are primarily used to maintain a consistent clamping force and prevent loosening of fasteners, especially in applications where vibration or shock is present. They are commonly found in:

The key advantages of using spring spacers include:

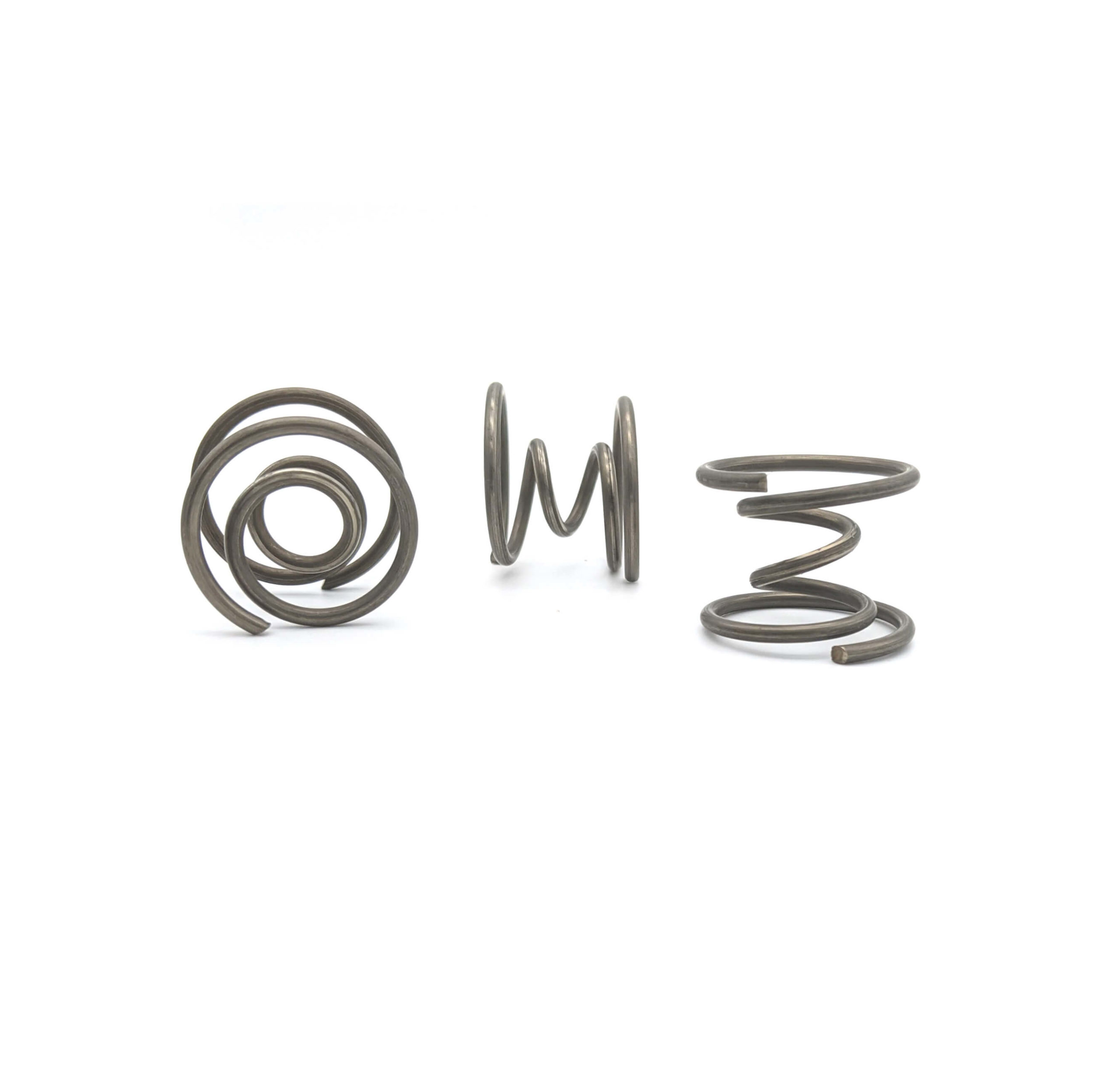

Coil springs, also known as helical springs, are versatile components that provide a spring force when compressed or extended. These springs are typically made by coiling a wire around a central axis, creating a helical shape. The amount of force exerted by a coil spring depends on several factors, including the spring material, wire diameter, coil diameter, and number of coils.

Coil springs find applications in a wide range of industries, including:

Key benefits of using coil springs include:

Choosing the right spring component depends on your specific application's needs and requirements. If your goal is to prevent loosening of fasteners and maintain a consistent clamping force, spring spacers are an excellent choice. However, if you need a component to absorb and release energy, provide a spring force, or act as a flexible support, coil springs are more appropriate.

Here are some key considerations when choosing between spring spacers and coil springs:

It's always a good idea to consult with a spring manufacturer or a qualified engineer to ensure you're selecting the best spring component for your specific application. They can provide expert advice, design recommendations, and help you choose the right material and dimensions for optimal performance and longevity.

In conclusion, both spring spacers and coil springs play vital roles in various applications. Spring spacers are excellent for preventing fastener loosening and maintaining consistent clamping force, while coil springs are ideal for providing flexibility, absorbing energy, and acting as a spring force. By carefully considering the application's requirements and seeking expert guidance, you can make the right choice and ensure the optimal performance of your design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.