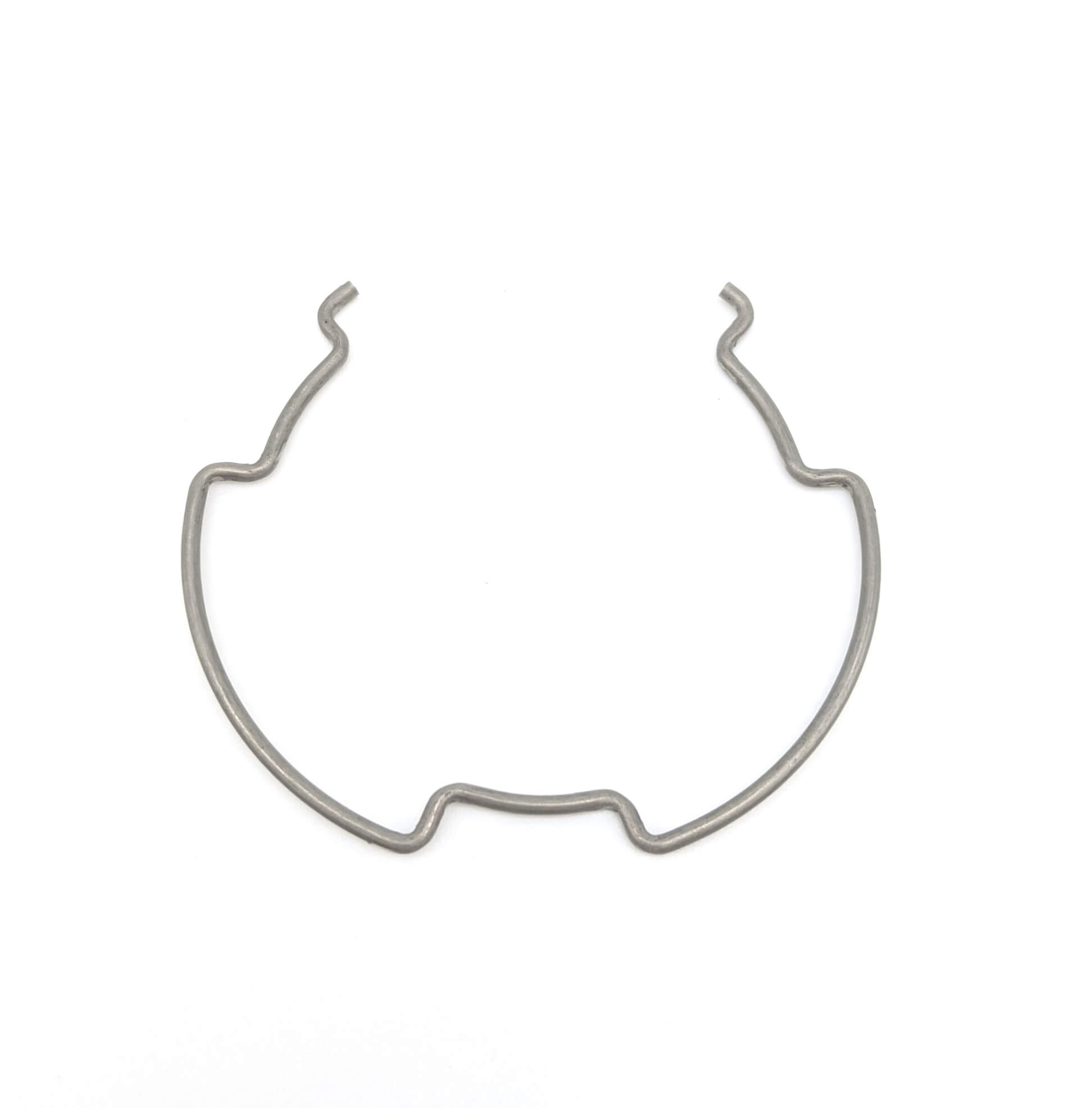

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring spacers and coil springs, while seemingly simple components, play a crucial role in a wide range of dynamic systems, from automotive suspension to industrial machinery. These springs are responsible

Spring spacers and coil springs, while seemingly simple components, play a crucial role in a wide range of dynamic systems, from automotive suspension to industrial machinery. These springs are responsible for storing and releasing energy, providing support, and absorbing shock, contributing significantly to the overall performance and longevity of these systems. This article delves into the intricacies of spring spacers and coil springs, exploring their design, materials, functions, and applications. It aims to provide a comprehensive understanding of these essential components and highlight their significance in modern engineering and technology.

Spring spacers, often overlooked but vital components, play a key role in fine-tuning the performance of spring-based systems. They are essentially solid pieces of material, typically made from metal or plastic, inserted between coil springs and other components. Their primary function is to alter the spring rate, effectively changing the stiffness of the system. By adjusting the spacer's thickness, engineers can fine-tune the spring's compression or extension characteristics.

The use of spring spacers offers several advantages. They allow for easy adjustment of spring rates without replacing the entire spring, offering a cost-effective solution for modifying system behavior. Additionally, they enable precise customization, ensuring the system operates optimally for specific applications. Spring spacers also help improve stability by preventing spring movement and ensuring consistent load distribution, vital for reliable performance.

Coil springs, the workhorse of many dynamic systems, are helical springs made by winding a wire around a cylindrical core. They are characterized by their ability to store and release energy when compressed or extended, acting as shock absorbers and providing support. The design of a coil spring is crucial to its performance, with factors such as wire diameter, coil diameter, and number of coils influencing the spring rate and load capacity.

Coil springs are crafted from a variety of materials, with spring steel being the most common choice due to its excellent elasticity and strength. However, other materials like stainless steel, phosphor bronze, and titanium may be employed for specific applications requiring corrosion resistance or other special properties.

Coil springs are available in various configurations to cater to diverse needs. The most common types include:

Choosing the right type of coil spring is crucial for optimal performance. Each type exhibits specific force-displacement characteristics, and selecting the appropriate configuration ensures the system operates as intended.

Spring spacers and coil springs are ubiquitous components, playing a vital role in numerous industries and technologies. Some notable applications include:

The future of spring spacers and coil springs is driven by ongoing advancements in materials science, manufacturing techniques, and design optimization. New materials with enhanced properties like high strength-to-weight ratios and improved fatigue resistance are being developed, enabling lighter and more durable springs.

The development of sophisticated simulation software allows engineers to optimize spring designs for specific applications, ensuring optimal performance and efficiency. Advancements in manufacturing processes enable the production of more intricate and customized spring designs, meeting the demands of increasingly complex and demanding applications.

Spring spacers and coil springs, often considered simple components, are indispensable for numerous dynamic systems. Their ability to store and release energy, provide support, and absorb shock makes them crucial for optimizing performance, enhancing stability, and ensuring longevity. As technology continues to evolve, the innovation and optimization of these essential components will remain critical, shaping the future of dynamic systems across various industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.