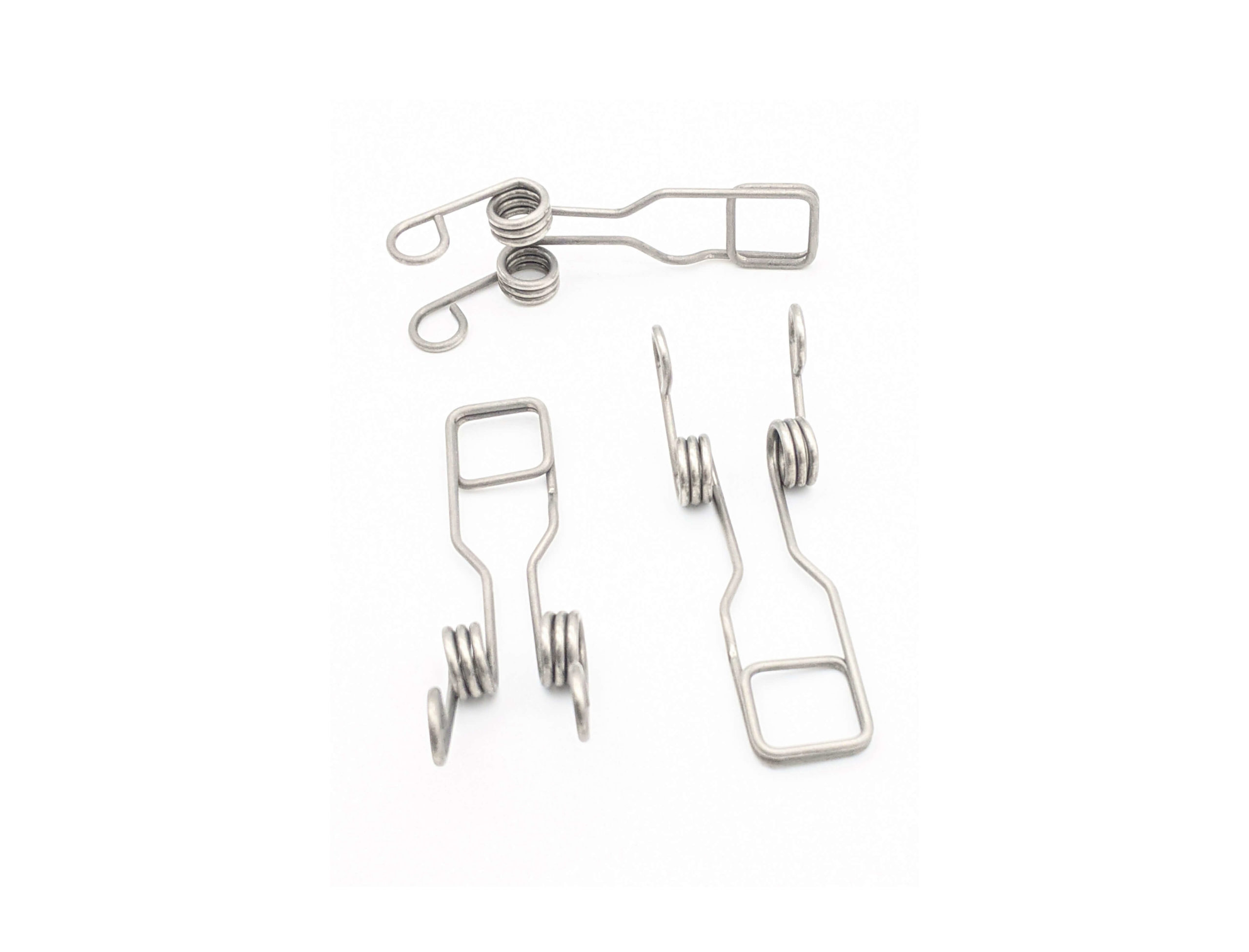

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the intricate world of engineering, precision is paramount, and springs play a vital role in ensuring the smooth and reliable operation of countless machines. From the delicate balance of

In the intricate world of engineering, precision is paramount, and springs play a vital role in ensuring the smooth and reliable operation of countless machines. From the delicate balance of a watch to the robust suspension of a vehicle, springs are the unsung heroes, silently providing the tension necessary for optimal performance. Spring precision, therefore, is not just a technical detail; it's the bedrock of functionality, ensuring that every component operates as intended, every time.

A spring, in its simplest form, is a resilient piece of material designed to store and release energy. It's a seemingly simple device, yet its design and manufacture involve an impressive level of precision. The spring's ability to exert a consistent force, known as tension, hinges on factors like material selection, coil diameter, wire thickness, and the spring's overall geometry. Even slight variations in these elements can dramatically alter the spring's performance, impacting the entire system it's designed to support.

In a world where tolerances are measured in thousandths of an inch, spring precision becomes crucial. Imagine a spring in a high-precision instrument like a medical device or a delicate watch mechanism. If the spring's tension is off, even by a fraction, the device could malfunction, leading to inaccurate readings or even catastrophic failure. In manufacturing, spring precision ensures consistent product quality and reliability, vital for maintaining production efficiency and customer satisfaction.

Spring precision begins with the selection of the right material. Spring steel, with its high tensile strength and elasticity, is a common choice. But even within this material, different grades exist, each offering unique properties. For high-temperature applications, specialized alloys are required, while corrosion resistance may be a critical factor in other environments. The material's composition and heat treatment processes significantly influence the spring's final properties, ensuring it meets the specific demands of the application.

The spring's coil design is another critical aspect. The number of coils, their spacing, and the wire's diameter all contribute to the spring's tension and its ability to compress or extend. A spring with tightly packed coils will generally have a higher spring rate, meaning it requires more force to compress or extend. Conversely, a spring with loosely spaced coils will have a lower spring rate, making it more flexible. Precision in coil engineering allows for precise control over these parameters, leading to a spring that meets the required tension specifications.

Once a spring is manufactured, rigorous testing is essential to verify its precision. These tests might involve measuring the spring's force at various compression or extension points, analyzing its fatigue resistance, and evaluating its ability to withstand environmental conditions. These tests ensure that the spring will perform consistently over time, meeting the demanding requirements of its intended use.

The impact of spring precision extends beyond individual components. It is essential for the overall functionality and reliability of a wide range of systems. Imagine a vehicle's suspension system; springs play a critical role in absorbing shock and ensuring a smooth ride. If these springs aren't precise, the ride could be uncomfortable, and the vehicle's handling could be compromised. In high-performance applications, like aerospace or automotive racing, spring precision becomes even more critical, as even the slightest variation can lead to significant performance differences.

Spring precision may seem like a subtle detail, but it's the foundation for reliable performance in countless applications. From the delicate mechanisms of a watch to the robust systems of a vehicle, springs are the silent workhorses, providing the tension needed for functionality and safety. By understanding the intricate interplay of material science, coil engineering, and rigorous testing, we can ensure that these tiny but powerful components deliver the precision required for a world of moving parts to operate seamlessly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.