Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring compression, a fundamental concept in physics and engineering, is the process of applying a force to a spring, causing it to shorten in length. This phenomenon is governed by

Spring compression, a fundamental concept in physics and engineering, is the process of applying a force to a spring, causing it to shorten in length. This phenomenon is governed by Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. Spring compression finds widespread applications in various industries, from automotive suspension systems to medical devices and everyday objects like door closers.

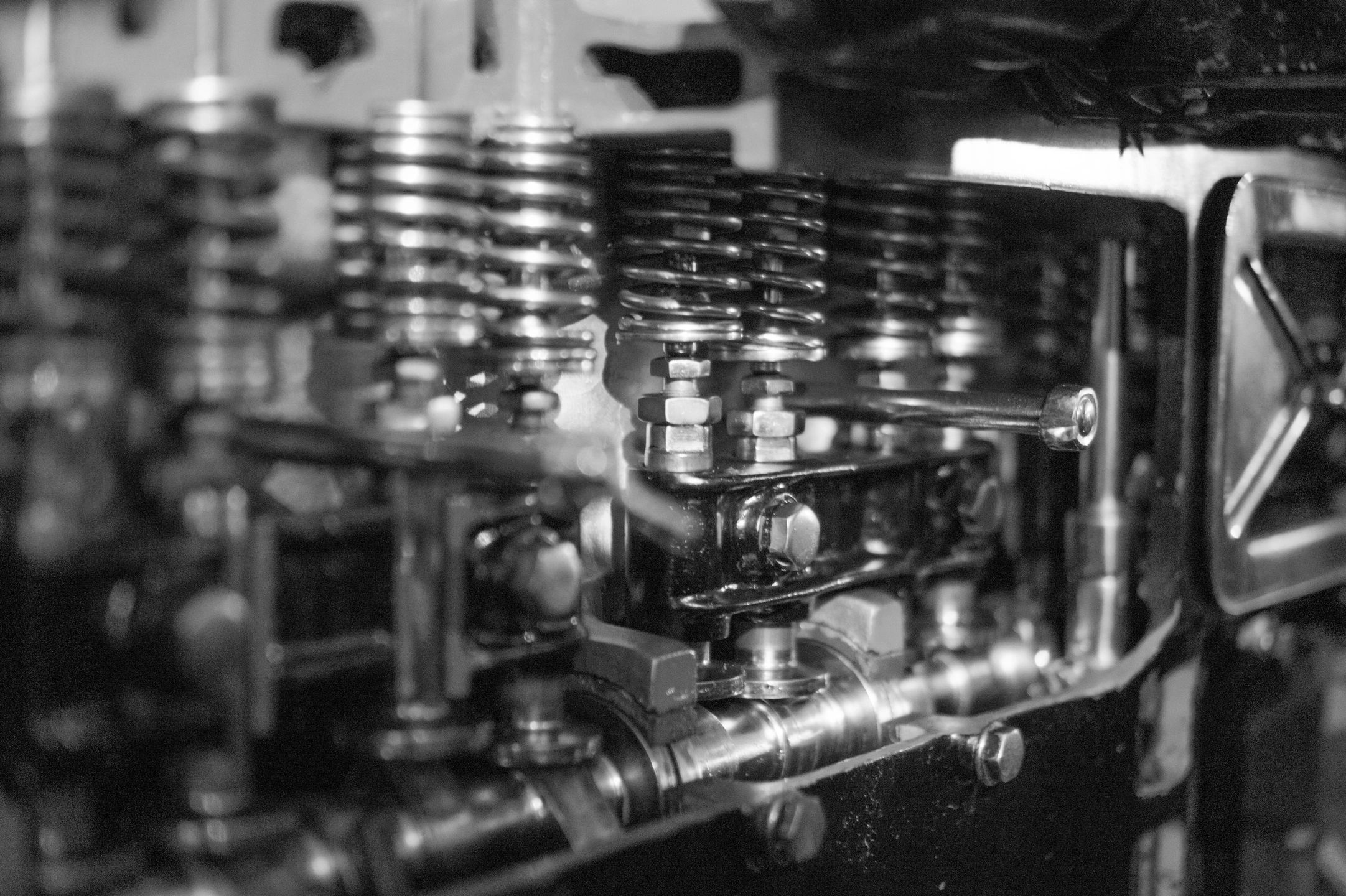

At its core, spring compression relies on the elastic properties of materials. Springs are typically made of materials that exhibit a high degree of elasticity, meaning they can deform under stress and return to their original shape when the stress is removed. This elastic behavior is crucial for storing and releasing mechanical energy.

When you compress a spring, you are essentially storing potential energy within its coils. This stored energy is proportional to the amount of compression applied. When the compression force is released, the spring exerts a force in the opposite direction, attempting to return to its original, uncompressed state. This force is what makes springs useful in various applications.

Hooke's Law provides a mathematical framework for understanding the relationship between the force applied to a spring and its resulting compression. It states that the force (F) exerted by a spring is directly proportional to its displacement (x) from its equilibrium position. Mathematically, this can be expressed as:

F = -kx

Where:

The negative sign indicates that the force exerted by the spring is always in the opposite direction of the displacement. For example, if you compress a spring, the force it exerts will push back against your compression force.

Springs come in various shapes and sizes, each designed for specific applications. Common types include:

The compression behavior of each spring type varies depending on its design and material properties. However, the fundamental principle of Hooke's Law applies to all springs.

Spring compression finds wide-ranging applications in various industries, including:

The amount of compression a spring experiences is affected by several factors, including:

Spring compression is a fundamental concept with far-reaching applications. Understanding the principles of Hooke's Law and the factors that influence spring compression is essential for engineers and designers working across various industries. Spring compression technology plays a crucial role in everything from automotive suspension systems to medical devices and everyday objects, making it an integral part of our modern world.

In conclusion, spring compression is a fascinating and essential concept in physics and engineering. The ability of springs to store and release mechanical energy, governed by Hooke's Law, enables them to find applications in a wide range of fields, from automotive and medical to consumer products and industrial machinery. Understanding the factors affecting spring compression allows for the design and implementation of these essential components in various applications, ensuring reliable and efficient operation in a multitude of systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.