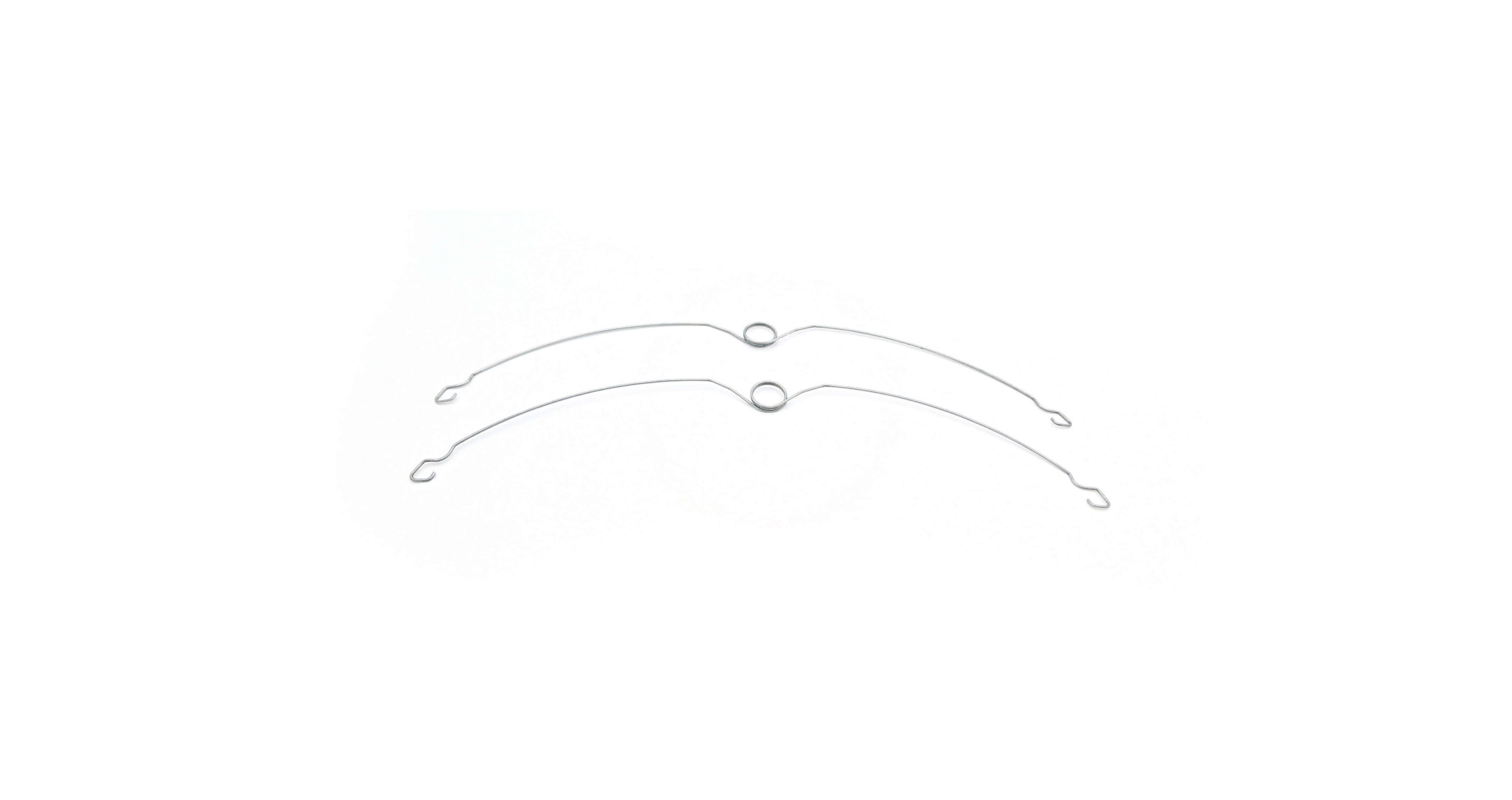

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring compression tools are indispensable for anyone working with springs, whether you're a professional mechanic, an avid DIY enthusiast, or a hobbyist. These tools are designed to safely compress or

Spring compression tools are indispensable for anyone working with springs, whether you're a professional mechanic, an avid DIY enthusiast, or a hobbyist. These tools are designed to safely compress or expand springs, enabling you to install and remove them without the risk of injury or damage to the spring or surrounding components. But with so many different types of spring compression tools available, choosing the right one for your specific needs can seem daunting. In this comprehensive guide, we'll delve into the world of spring compression tools, exploring their various types, key features, and applications. We'll also provide practical tips to help you select the ideal tool for your project and ensure safe and efficient spring handling.

Spring compression tools are specialized devices that allow you to safely and efficiently compress or expand springs. They come in various shapes and sizes, each designed to handle specific spring types and applications. A spring compression tool is essentially a device that helps to manage the force of a spring. Springs are designed to store energy and when they are compressed or stretched, they release a significant amount of force. Without a spring compression tool, it's very dangerous to handle springs as the force can cause serious injury or even death.

The primary function of a spring compression tool is to hold a spring in a compressed state, allowing you to install or remove it without it suddenly springing back to its original length. These tools are essential for applications where springs are used to exert force, such as automotive suspension systems, industrial machinery, and even household appliances.

The world of spring compression tools is diverse, catering to a wide range of spring types and sizes. Understanding the different types available is crucial for choosing the right tool for your needs.

C-clamp style spring compression tools are among the most common and versatile. They feature a C-shaped frame with adjustable jaws that clamp onto the spring. The C-clamp mechanism provides a secure grip on the spring, allowing you to compress it safely. They're commonly used in automotive applications, like replacing shock absorbers and suspension springs.

Internal spring compression tools are designed for springs that are located inside a confined space, like the coil springs in a shock absorber. These tools have a central shaft that extends into the spring, and adjustable jaws that grip the outer coils. They are typically more specialized than C-clamp style tools but offer greater precision and control for compressing springs in tight spaces.

External spring compression tools are used for compressing springs that are located outside a confined space, like the springs found in a garage door opener or a spring-loaded mechanism. These tools feature a pair of adjustable arms that grip the outer coils of the spring, allowing you to compress it while keeping the spring securely in place. These tools are often preferred for applications where the spring needs to be compressed while still allowing access to other components or mechanisms.

Hydraulic spring compression tools utilize hydraulic pressure to compress springs. They are typically used in heavier-duty applications, where the springs are larger and require significant force to compress. The advantage of hydraulic spring compression tools is their ability to provide a high degree of control and precision during compression. They are also particularly suitable for springs that are difficult to reach or located in tight spaces.

Selecting the appropriate spring compression tool is crucial for safe and efficient spring handling. Consider these factors when making your choice:

The size and type of the spring will determine the best tool for the job. C-clamp style tools are suitable for smaller springs, while hydraulic tools are designed for larger and heavier springs. If you are working with a spring that has a special shape or design, you may need a specialized compression tool.

The specific application for which you're using the spring compression tool will influence your choice. For automotive work, a C-clamp style tool or an internal spring compression tool is usually sufficient. If you need to compress a spring in a tight space, an internal tool may be the better choice. For heavier-duty industrial applications, a hydraulic spring compression tool is typically the most suitable option.

Spring compression tools range in price, from budget-friendly C-clamp style tools to more expensive hydraulic tools. Determine the appropriate tool based on your needs and budget.

Safety should always be your top priority when working with spring compression tools. Always make sure that the tool is properly rated for the spring you're using and follow all safety instructions provided by the manufacturer. Never use a tool that is damaged or worn out, and always wear appropriate safety gear, such as gloves and eye protection.

Working with springs can be dangerous, but by taking the right precautions, you can minimize the risks and ensure safe and efficient spring handling. Here are some important tips:

The first step to safe spring handling is using the right tools. Always select a spring compression tool that is specifically designed for the type of spring you are working with. A properly designed tool will provide a secure grip on the spring and prevent it from suddenly springing back to its original length.

Always use a spring compressor when working with springs. A spring compressor will securely hold the spring in a compressed state, reducing the risk of injury from the spring suddenly springing back to its original length.

Always wear safety gear, such as gloves and eye protection, when working with springs. Springs can be sharp and can cause serious injuries if they come into contact with your skin or eyes.

Be aware of the spring's force and the potential danger it poses. Never attempt to compress a spring without a spring compressor, and always take precautions to protect yourself from potential injuries.

Inspect the spring before using it to make sure it is not damaged or worn out. A damaged or worn-out spring can be dangerous and should not be used.

Spring compression tools are essential for anyone working with springs. By understanding the different types of tools available and following the tips for safe and efficient spring handling, you can minimize the risks and ensure that your projects are completed safely and effectively. Whether you're a professional mechanic or a DIY enthusiast, spring compression tools are a valuable investment for any toolbox.

Spring compression tools are essential for anyone working with springs, allowing for safe and efficient installation and removal. By understanding the different types, selecting the appropriate tool, and following safety guidelines, you can ensure a smooth and risk-free experience when handling these powerful components. Remember to always prioritize safety and use the right tools for the job to avoid potential injuries and ensure your projects are completed successfully.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.