Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring compression tools are indispensable for anyone working with springs, whether you're a professional mechanic tackling engine repairs or a DIY enthusiast tackling home projects. These tools allow you to

Spring compression tools are indispensable for anyone working with springs, whether you're a professional mechanic tackling engine repairs or a DIY enthusiast tackling home projects. These tools allow you to safely and efficiently compress springs, preventing potential injuries and damage to the spring itself. Spring compression tools come in various designs, each suited for specific applications. Choosing the right tool ensures a smooth and successful spring compression process. This guide will explore different types of spring compression tools, their uses, and tips for choosing the right tool for your needs.

Spring compression tools are designed to safely compress springs, allowing for the removal or installation of components that rely on the spring's tension. These tools hold the spring in a compressed state, preventing it from suddenly releasing and causing potential harm or damage. They are essential for tasks involving:

There are various types of spring compression tools, each designed for different applications and spring sizes. Some of the most common types include:

A C-clamp spring compressor is a simple and versatile tool. It consists of two arms that are clamped around the spring, allowing for gradual compression. C-clamp compressors are ideal for smaller springs and are often used in DIY projects.

External spring compressors are designed to compress springs from the outside, using a threaded mechanism to adjust the compression force. These tools are often used for larger springs, such as those found in automotive suspension systems. External spring compressors are generally more robust and provide more control over the compression process.

Internal spring compressors are used to compress springs from the inside, using a pair of jaws that grip the spring's inner diameter. These tools are typically used for smaller springs and are often found in automotive repair kits. Internal spring compressors are particularly useful when the spring is inaccessible from the outside.

Hydraulic spring compressors offer precision and powerful compression force. These tools use hydraulic pressure to compress the spring, providing excellent control and the ability to handle even the most stubborn springs. Hydraulic spring compressors are often preferred for heavy-duty applications and professional mechanics.

When choosing a spring compression tool, several factors need to be considered:

Spring compression can be dangerous if not done correctly. Always prioritize safety by taking these precautions:

To maximize safety and efficiency when using spring compression tools, follow these tips:

Spring compression tools are essential for anyone working with springs, offering a safe and efficient way to manage spring tension. By understanding the different types of tools, choosing the right one for the job, and following safety precautions, you can ensure a smooth and successful spring compression process. Always prioritize safety and use caution when working with springs and spring compression tools.

Spring compression tools are valuable tools for anyone working with springs, from professional mechanics to DIY enthusiasts. Their use allows for the safe removal or installation of components relying on spring tension, preventing injuries and damage. By understanding different types of spring compression tools, choosing the right one for the job, and following safety precautions, you can confidently work with springs while ensuring your safety and the longevity of your project.

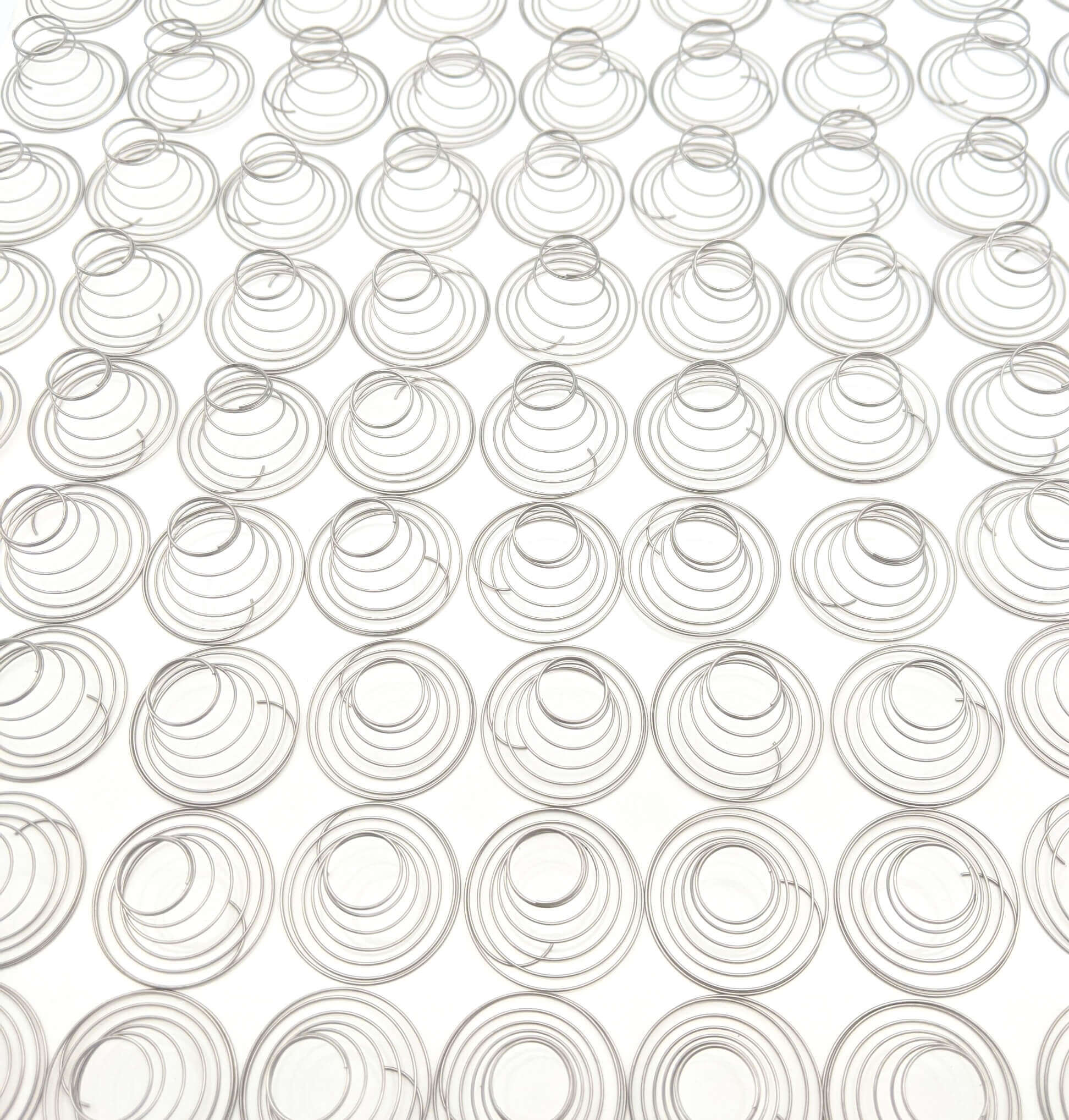

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.