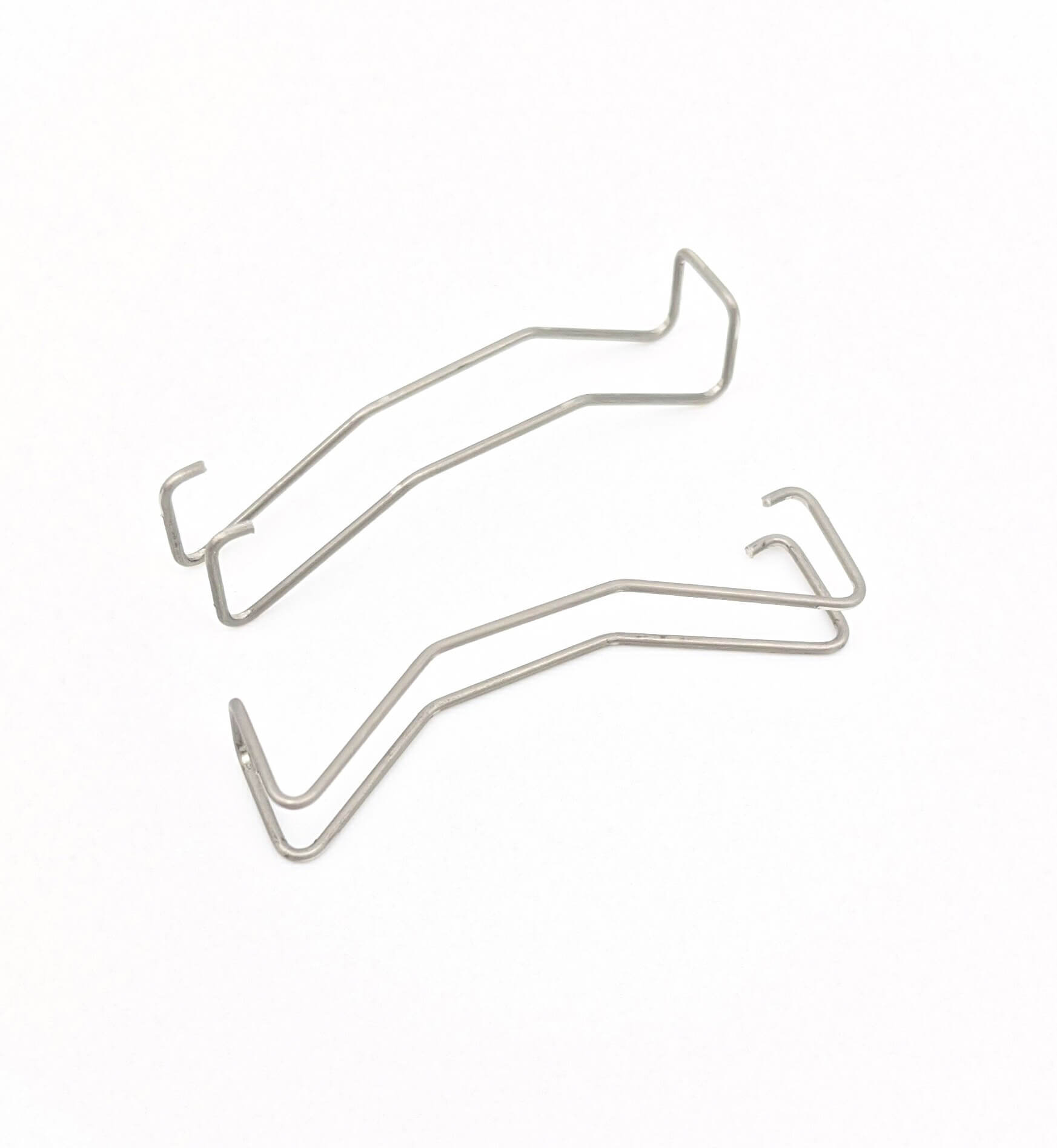

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring compression is a fundamental concept in engineering, and stainless steel is a material of choice for numerous applications. This article delves into the world of spring compression, exploring the

Spring compression is a fundamental concept in engineering, and stainless steel is a material of choice for numerous applications. This article delves into the world of spring compression, exploring the advantages of using stainless steel in this context. We'll discuss the properties that make stainless steel ideal for springs, the various types of stainless steel springs, and the numerous industries where they excel. Get ready to understand why stainless steel springs are a vital component in countless applications, from everyday objects to critical machinery.

Spring compression is a vital principle in mechanics, enabling the storage and release of energy. The idea is simple: apply force to a spring, compressing it, and then allow that stored energy to be released, performing work. Springs are found everywhere, from the tiny ones in ballpoint pens to the massive ones used in heavy machinery. The key is finding the right material for the job, and that's where stainless steel shines.

Stainless steel is a remarkably resilient alloy, boasting a unique combination of properties that make it perfect for spring applications. Here's why:

These properties make stainless steel a go-to choice for springs in numerous industries.

There are various types of stainless steel springs, each tailored to specific applications. Here are a few common types:

The choice of spring type depends on the specific requirements of the application, including the load, space constraints, and operating conditions.

Stainless steel springs are ubiquitous, playing crucial roles in diverse industries. Here are a few examples:

The versatility and performance of stainless steel springs make them an essential component in countless industries.

Stainless steel is not a single material, but rather a family of alloys. Each grade of stainless steel possesses unique properties, making it important to choose the right grade for your spring application. Some common grades used for spring applications include:

Consulting with a spring manufacturer is crucial to select the appropriate stainless steel grade for your specific needs.

Stainless steel springs are a testament to the ingenuity of engineering. Their exceptional properties, including corrosion resistance, strength, durability, and fatigue resistance, make them a reliable solution for a wide range of applications. From everyday objects to critical machinery, stainless steel springs continue to perform silently, ensuring smooth operation and lasting performance. So next time you encounter a spring, take a moment to appreciate the power of this seemingly simple yet vital component.

The world of spring compression is a fascinating one, and stainless steel plays a pivotal role in this field. By understanding the advantages of stainless steel springs, we gain insight into the remarkable capabilities of this material and its impact on various industries. Whether it's a tiny spring in a pen or a massive one in a heavy-duty machine, stainless steel springs continue to shape our world, offering a blend of strength, durability, and reliability that is hard to match.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.