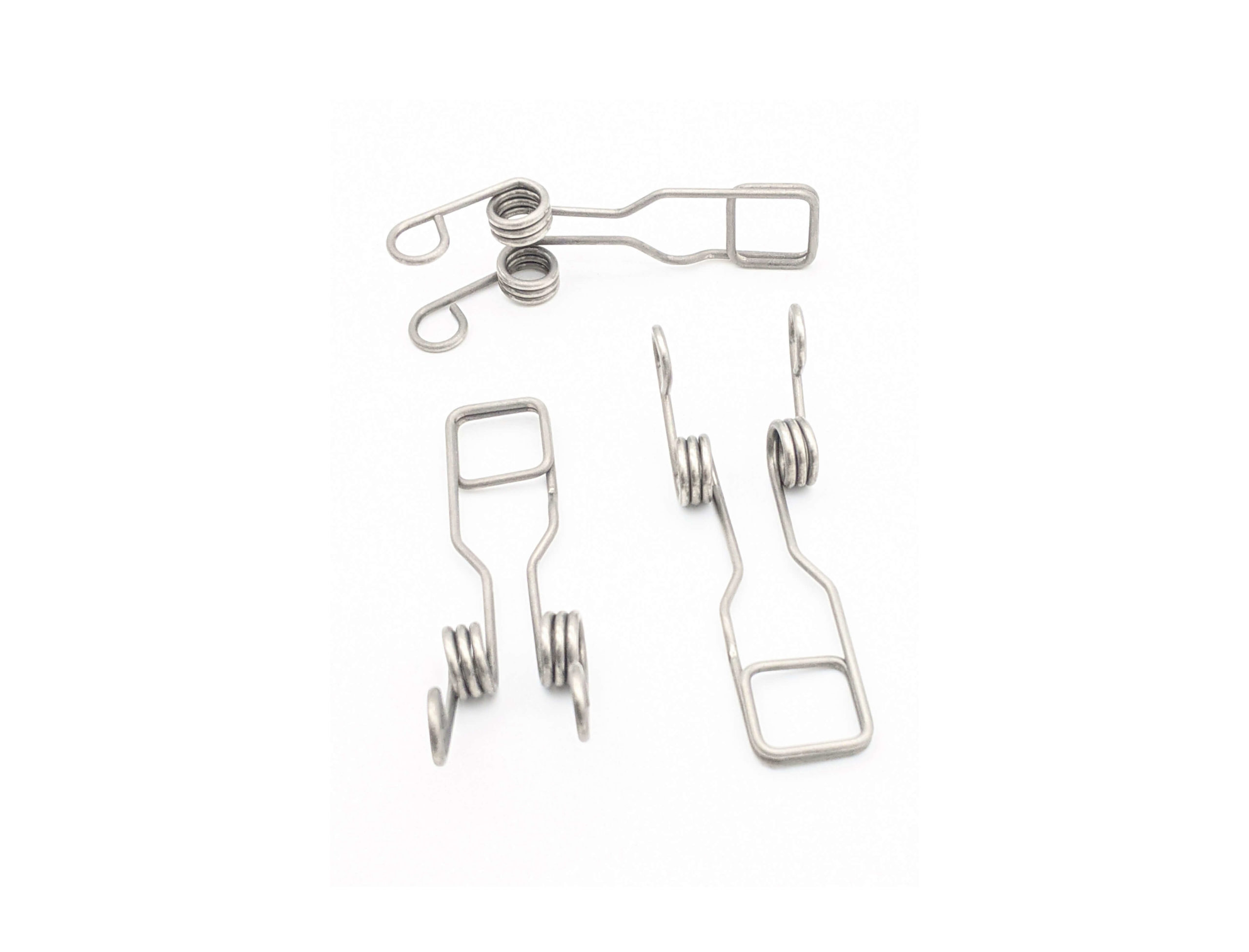

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

The spring compression test is a fundamental procedure in engineering and manufacturing, particularly in industries relying on springs for various applications. This test evaluates the spring's ability to withstand compressive

The spring compression test is a fundamental procedure in engineering and manufacturing, particularly in industries relying on springs for various applications. This test evaluates the spring's ability to withstand compressive force without permanently deforming or failing. It's essential for ensuring the spring's reliability, determining its load capacity, and predicting its lifespan under specific operating conditions. Whether you're designing a new product or simply need to ensure the quality of existing springs, understanding the spring compression test is crucial.

Springs are ubiquitous components found in countless products and systems, from simple door hinges and car suspensions to complex machinery and medical devices. Their primary function is to store and release mechanical energy, providing flexibility, resilience, and support in various applications. The ability of a spring to perform its intended function reliably and safely hinges on its ability to withstand compression forces without failing. This is where the spring compression test comes in.

A spring compression test is a controlled procedure that subjects a spring to increasing compressive forces while measuring its deformation and behavior. The test results provide valuable insights into the spring's mechanical properties, including its spring rate, yield strength, and fatigue life. This information is critical for:

* **Design Optimization:** Understanding the spring's behavior under compression allows engineers to design springs that meet specific load requirements and performance goals.

* **Quality Control:** Regular compression testing ensures that springs manufactured in bulk meet pre-determined quality standards, minimizing the risk of faulty or unreliable components.

* **Predictive Maintenance:** Compression tests can help identify potential issues with springs, enabling preventative maintenance measures to avoid premature failures and costly downtime.

There are several types of spring compression tests, each designed to evaluate specific aspects of a spring's performance. Common tests include:

* **Static Compression Test:** In this test, a spring is subjected to a steady compressive force, and its deflection (change in length) is measured. This test determines the spring rate, which is the ratio of force to deflection.

* **Cyclic Compression Test:** This test involves repeatedly compressing and releasing a spring for a specified number of cycles. The test evaluates the spring's fatigue life, which is the number of cycles it can withstand before failing.

* **Endurance Compression Test:** This test is similar to the cyclic compression test but is performed over a longer duration and typically involves a lower load. It's used to determine the spring's long-term performance and resistance to creep (slow deformation over time).

The results of a spring compression test are influenced by several factors, including:

* **Material Properties:** The material the spring is made of (e.g., spring steel, phosphor bronze) plays a significant role in its compression characteristics. Different materials have different elastic limits, yield strengths, and fatigue strengths.

* **Spring Design:** The geometry and dimensions of the spring, including its wire diameter, coil diameter, and number of coils, directly impact its spring rate and compression behavior.

* **Environmental Conditions:** Factors like temperature and humidity can influence the spring's mechanical properties and affect the test results. For instance, high temperatures can reduce the spring's elastic limit and increase its creep rate.

A spring compression test is typically performed using a dedicated testing machine. The spring is secured within the machine's clamps, and a controlled compressive force is applied. The machine measures the spring's deflection using sensors or other measurement devices. The test data is then used to generate a force-deflection curve, which provides valuable insights into the spring's behavior. The test setup, force application method, and measurement accuracy are critical factors in obtaining reliable and accurate test results.

Interpreting the results of a spring compression test requires understanding the key parameters:

* **Spring Rate:** Indicates the force required to compress the spring by a specific distance. A higher spring rate means the spring is stiffer and requires more force to compress.

* **Yield Strength:** Represents the maximum stress the spring can withstand without permanent deformation. This is crucial for ensuring the spring retains its shape and functionality even under heavy loads.

* **Fatigue Life:** Indicates the number of compression cycles the spring can withstand before failing due to fatigue. A high fatigue life is essential for applications involving repetitive loading, like automotive suspension systems.

Spring compression testing is essential in various industries, including:

* **Automotive:** Testing suspension springs, valve springs, and other components to ensure their reliability and safety.

* **Aerospace:** Testing springs used in aircraft landing gear, control systems, and other critical components.

* **Medical Devices:** Testing springs used in medical implants, surgical instruments, and other devices to ensure their biocompatibility and performance.

* **Electronics:** Testing springs used in connectors, switches, and other components to ensure their reliability and durability.

The spring compression test is a fundamental procedure for evaluating the strength, resilience, and reliability of springs used in diverse applications. This test provides critical insights into the spring's mechanical properties, enabling engineers and manufacturers to design, manufacture, and maintain springs that meet stringent performance requirements. By understanding the principles behind spring compression testing, you can ensure the optimal performance, safety, and longevity of springs in various engineering applications.

From automotive suspensions to delicate medical devices, springs play a crucial role in countless aspects of our modern world. Ensuring the quality and reliability of these components is paramount, and spring compression testing stands as a cornerstone in achieving this goal. Whether you're a design engineer, a quality control specialist, or a maintenance technician, understanding the fundamentals of spring compression testing empowers you to make informed decisions and contribute to the development of safe and robust products.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.