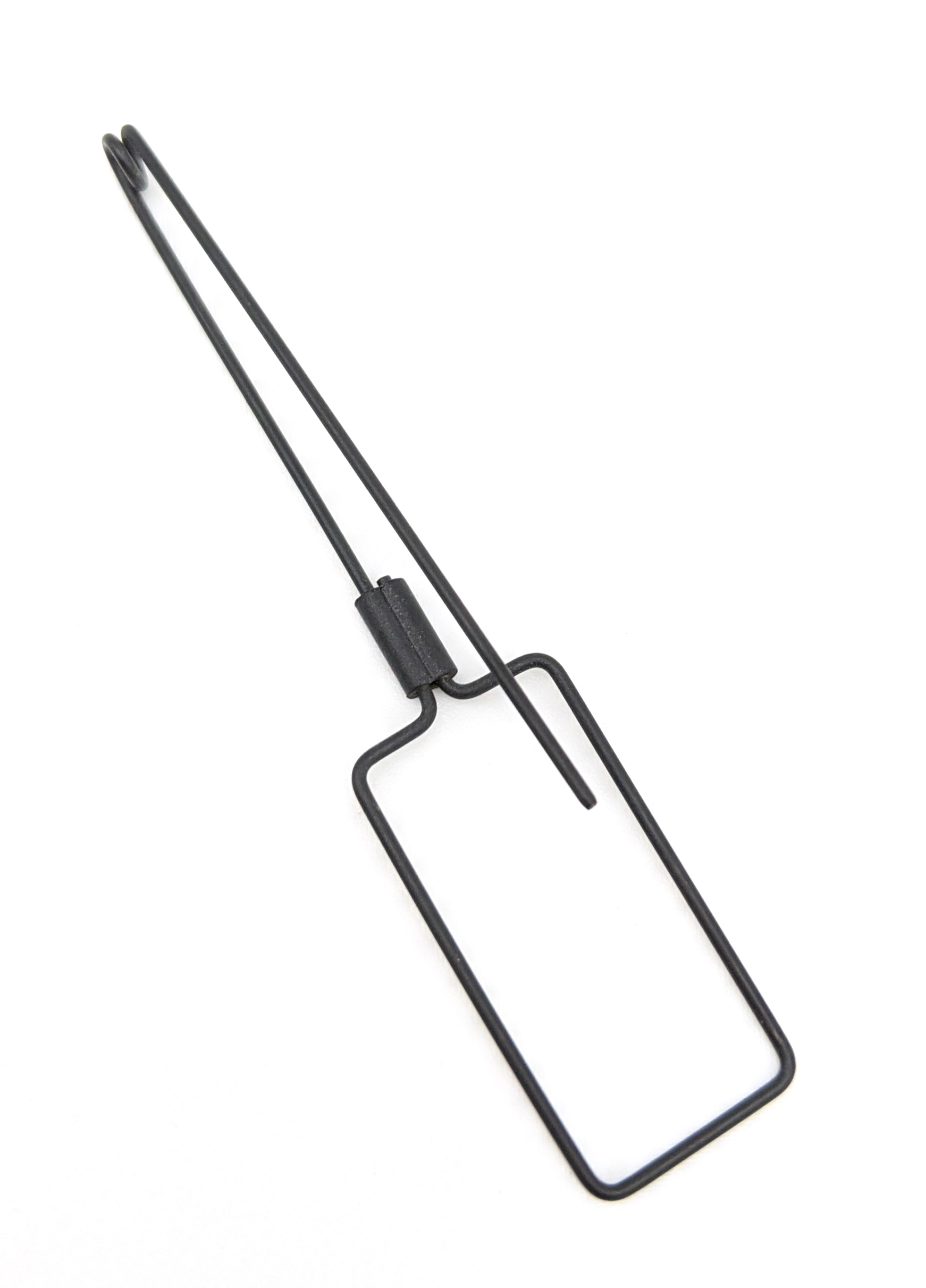

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Spring compression is a crucial aspect of mechanical design, particularly in applications demanding resilience, strength, and durability. Stainless steel springs excel in such scenarios, offering excellent resistance to corrosion and

Spring compression is a crucial aspect of mechanical design, particularly in applications demanding resilience, strength, and durability. Stainless steel springs excel in such scenarios, offering excellent resistance to corrosion and fatigue, making them ideal for various industries. This article delves into the intricacies of spring compression, highlighting the unique properties of stainless steel springs and exploring their diverse applications across different sectors.

Spring compression refers to the act of applying force to a spring, causing it to shorten in length. This force is directly related to the spring's stiffness, which determines how much it compresses under a given load. The ability of a spring to resist compression is crucial in various applications, allowing it to store energy and provide a restoring force when released.

Stainless steel stands out as a preferred material for springs due to its exceptional properties. These alloys offer a remarkable blend of strength, corrosion resistance, and fatigue life. The high tensile strength of stainless steel allows springs to withstand significant compressive forces without deformation. Moreover, its resistance to corrosion makes it ideal for environments where exposure to moisture, chemicals, or harsh conditions is a concern. This is particularly crucial in industries like aerospace, automotive, and medical, where components must function flawlessly under demanding conditions.

The superior fatigue life of stainless steel springs is another key advantage. Fatigue refers to the gradual weakening of a material under repeated stress cycles. Stainless steel exhibits excellent resistance to fatigue, ensuring that springs maintain their functionality over extended periods even under frequent compression and release cycles.

Stainless steel springs come in various forms, each tailored to specific applications. Common types include:

The versatility and durability of stainless steel springs make them indispensable across numerous industries. Here's a glimpse into their diverse applications:

Stainless steel springs play a vital role in the automotive industry, contributing to the performance, safety, and comfort of vehicles. Examples include:

In aerospace, the demanding requirements of flight necessitate components that are lightweight, durable, and reliable. Stainless steel springs meet these criteria flawlessly, finding application in:

The medical industry demands materials that are biocompatible, corrosion-resistant, and sterile. Stainless steel springs excel in these areas, making them crucial in:

Industrial machinery often operates in harsh environments, requiring robust components that can withstand wear and tear. Stainless steel springs contribute to the efficiency and reliability of industrial equipment by:

When working with springs, it's essential to consider factors that affect their compression behavior. These include:

To ensure the quality and performance of stainless steel springs, rigorous testing is crucial. Common tests include:

Spring compression is a fundamental concept in mechanical engineering, with stainless steel springs playing a critical role in various applications. Their exceptional strength, corrosion resistance, and fatigue life make them a reliable and durable choice for industries ranging from automotive and aerospace to medical and industrial machinery. By understanding the properties and applications of stainless steel springs, engineers can design and build machines, devices, and structures that are robust, efficient, and reliable.

In the world of mechanical engineering, spring compression is a silent but powerful force. Stainless steel springs embody this strength, offering a balance of resilience, durability, and adaptability. As technology advances, the demand for reliable, corrosion-resistant springs continues to grow, making stainless steel a cornerstone material for innovation and progress. By embracing the unique properties of these springs, we unlock a world of possibilities, pushing the boundaries of what we can design and build.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.