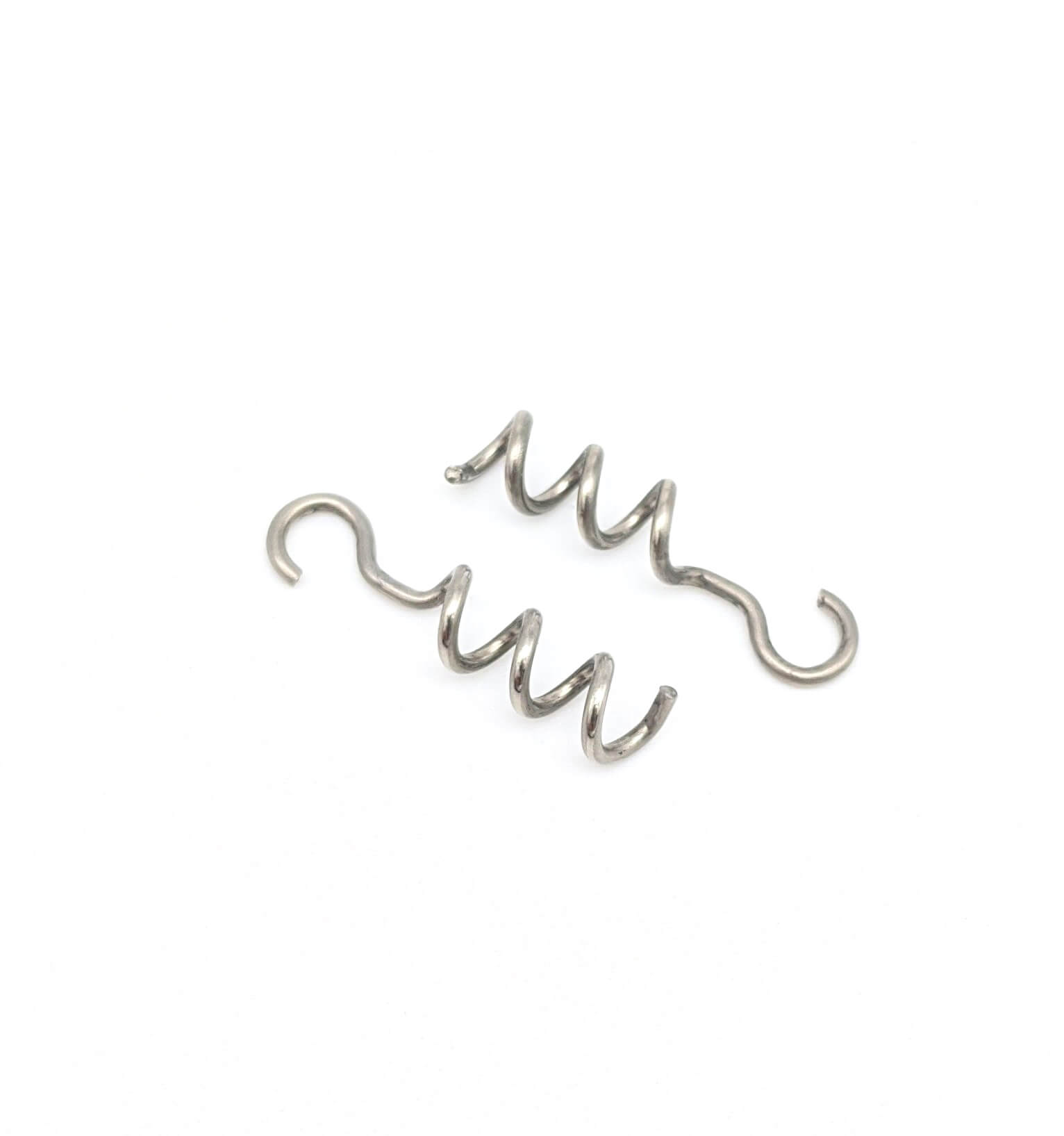

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are ubiquitous in our daily lives, from the simple act of bouncing a ball to the intricate workings of a car's suspension system. These seemingly mundane devices hold a

Springs are ubiquitous in our daily lives, from the simple act of bouncing a ball to the intricate workings of a car's suspension system. These seemingly mundane devices hold a surprising amount of physics within their coiled forms. One of the most fundamental concepts related to springs is the spring compression equation, which allows us to predict how much a spring will compress under a given load. This article delves into the intricacies of this equation, exploring its derivation, applications, and limitations.

At its core, the spring compression equation is a mathematical expression that relates the force applied to a spring to the resulting compression or extension. It's based on Hooke's Law, a fundamental principle in physics that states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position.

The equation itself is surprisingly simple:

F = -kx

Where:

* F is the force applied to the spring (in Newtons)

* k is the spring constant (in Newtons per meter, N/m), which represents the stiffness of the spring

* x is the displacement from the equilibrium position (in meters)

The negative sign indicates that the force exerted by the spring is in the opposite direction to the displacement. This means that if you compress a spring, it will push back with an equal and opposite force. Conversely, if you stretch the spring, it will pull back with an equal and opposite force.

The spring constant (k) is a crucial parameter in the spring compression equation. It embodies the fundamental property of a spring - its stiffness. A higher spring constant signifies a stiffer spring, requiring more force to achieve a given displacement. Conversely, a lower spring constant represents a more flexible spring, easily compressed or extended.

The value of the spring constant depends on various factors, including the material the spring is made of, its geometry (wire diameter, number of coils, coil diameter), and how the spring is manufactured. Imagine two springs made of the same material: one thick and tightly coiled, the other thin and loosely coiled. The thick, tightly coiled spring will be much stiffer and have a higher spring constant than the thin, loosely coiled spring.

The spring compression equation finds applications in countless scenarios, ranging from everyday objects to sophisticated engineering systems. It's used in:

* Mechanical Design: Engineers use the equation to design springs for various applications, ensuring the spring can handle the intended load and displacement. This is crucial in everything from door hinges to automotive suspension systems.

* Physics Experiments: In labs, the spring compression equation is used to study the principles of simple harmonic motion, a fundamental oscillation pattern observed in many physical systems.

* Medical Devices: Springs are essential components in medical devices like surgical instruments, where precise force control is vital.

* Robotics and Automation: In robotics, springs are used for shock absorption, energy storage, and actuation, all governed by the principles of spring compression.

While the spring compression equation is a powerful tool, it's important to remember that it's based on idealized assumptions. Real-world springs often exhibit behavior that deviates from the ideal. These deviations can arise from factors such as:

* Nonlinearity: Hooke's Law assumes a linear relationship between force and displacement. However, real springs can exhibit nonlinear behavior, particularly at large displacements. This means the spring compression equation may not accurately predict the force for larger deformations.

* Damping: Real springs lose energy due to friction and internal forces, a phenomenon known as damping. This energy loss can cause oscillations to decay over time, affecting the accuracy of the spring compression equation.

* Spring Material Properties: The properties of the spring material can affect its behavior under load. For example, fatigue or creep can occur at high stresses, leading to changes in the spring constant over time.

While the spring compression equation provides a fundamental understanding of spring behavior, it's crucial to acknowledge its limitations. Real-world applications often necessitate a more nuanced approach that accounts for the complexities of spring behavior. Advanced techniques like finite element analysis (FEA) can provide more accurate predictions for complex spring systems.

The spring compression equation is not just a mathematical formula; it's a window into the world of springs and their intricate interactions with forces and motion. By delving deeper into this equation and its applications, we gain a richer understanding of the ubiquitous role springs play in our lives.

The spring compression equation, derived from Hooke's Law, is a fundamental principle in understanding the behavior of springs. It allows us to predict the force exerted by a spring when it is compressed or extended. While this equation provides a powerful tool, it is important to recognize its limitations and acknowledge the complexities of real-world springs. By understanding these nuances, we can better harness the power of springs in various applications, from everyday objects to advanced engineering systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.