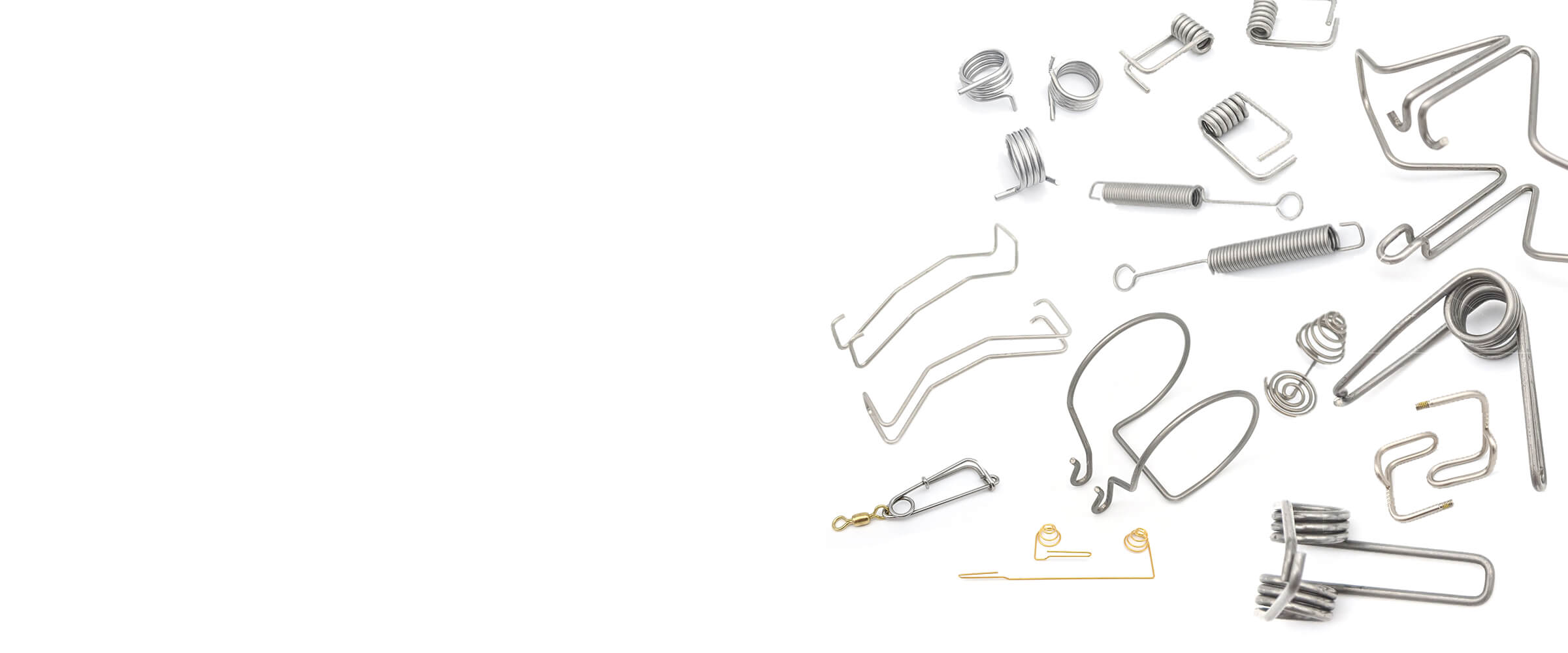

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Working with springs, especially those found in automotive suspension systems, can be a daunting task. These coiled metal marvels store significant energy, and when compressed or released, can pose serious

Working with springs, especially those found in automotive suspension systems, can be a daunting task. These coiled metal marvels store significant energy, and when compressed or released, can pose serious safety hazards. This is where the spring coil compressor tool comes in. This invaluable piece of equipment, designed specifically to safely compress and decompress springs, is a must-have for any mechanic or DIY enthusiast tackling spring-related repairs. This comprehensive guide will delve into the world of spring coil compressor tools, exploring their types, features, usage, and the importance of safety while using them. We'll also provide you with valuable tips for selecting the right tool for your needs.

A spring coil compressor tool, also known as a spring clamp, is a specialized tool designed to safely compress and decompress coil springs, commonly found in automotive suspension systems. These tools essentially hold the spring in a compressed state, allowing mechanics and DIY enthusiasts to safely remove and replace components like shock absorbers, struts, and other suspension parts. Imagine trying to remove a spring without a compressor tool - it's like trying to hold a tightly wound, highly energetic coil in your hands, which can easily lead to injury. Fortunately, spring coil compressor tools eliminate this risk, making spring-related repairs significantly safer and easier.

Spring coil compressor tools come in various types, each suited for specific applications. Here are some common types:

1. External Spring Compressor Tools: These tools work by clamping onto the outside of the coil spring, compressing it from the exterior. They are typically used for compressing springs on vehicles with ample clearance around the spring. External compressors are often adjustable and feature a screw mechanism to control the compression force.

2. Internal Spring Compressor Tools: These tools utilize a pair of arms that slide inside the coil spring, compressing it from the inside. Internal compressors are often preferred for applications where there is limited clearance around the spring, as found in some car models.

3. Hydraulic Spring Compressor Tools: Offering a combination of power and precision, these tools use hydraulic pressure to compress the spring. Hydraulic spring compressors provide a smooth, controlled compression, making them ideal for heavy-duty applications and large springs. They typically feature a hand pump or air compressor to generate the hydraulic pressure.

4. Air-Powered Spring Compressor Tools: Designed for ultimate convenience, these tools utilize compressed air to power the compression mechanism. Air-powered compressors offer quick and efficient spring compression, making them suitable for busy workshops and mechanics who prioritize speed.

The choice of spring coil compressor tool depends on various factors, including the type of vehicle, the spring's size, and the available space around the spring. Consider the following factors when selecting a tool:

1. Spring Size: Make sure the tool has a capacity that matches the spring you need to compress. Check the tool's specifications to ensure it can handle the spring's diameter and length.

2. Vehicle Type: Different vehicles have different suspension designs and spring sizes. Select a tool designed specifically for your vehicle or application.

3. Clearance: Consider the available space around the spring. If space is limited, you might need an internal compressor. External compressors are suitable for applications with ample clearance.

4. Safety Features: Always prioritize safety. Look for tools with features like safety locks, pressure release valves, and sturdy construction to ensure your safety while using the tool.

Using a spring coil compressor tool may seem intimidating, but following these steps will ensure a safe and efficient compression process:

1. Preparation: Ensure you have the appropriate spring compressor tool for your vehicle and spring. Secure the vehicle properly using jack stands or ramps, and remove the wheel that corresponds to the spring you'll be working on. Prepare the work area, ensuring it is clear of any obstacles.

2. Compressing the Spring: Carefully position the spring compressor tool around the spring. Ensure the tool is securely clamped to the spring and that the compression arms are evenly distributed around the coils. Begin compressing the spring slowly and steadily, paying close attention to the tool's operation and any resistance you encounter.

3. Disassembly: Once the spring is compressed to the desired length, remove the suspension components you need to replace, such as the shock absorber or strut. Remember, always maintain control over the spring during the disassembly process to avoid accidents. Never leave a compressed spring unattended, as it could suddenly release and cause injury.

4. Assembly: Install the new components, ensuring they are properly aligned and secured. Carefully release the spring compressor tool, slowly decompressing the spring. Never force the spring compressor tool to release. If you encounter any resistance, double-check the alignment of the tools and components.

5. Finishing Touches: Once the spring is fully decompressed, carefully remove the spring compressor tool. Reinstall the wheel and ensure all nuts and bolts are properly tightened. Always inspect the suspension components for any damage or wear before driving the vehicle.

Spring compression can be dangerous if safety measures aren't taken. Always prioritize safety and follow these important precautions:

1. Always wear safety glasses and gloves to protect your eyes and hands from potential debris and injuries.

2. Never attempt to compress or decompress springs without a suitable tool. Using makeshift tools can be extremely dangerous.

3. Never attempt to compress or decompress springs while under load. Ensure the vehicle is properly secured and the spring is free from any weight.

4. Never leave a compressed spring unattended. It could suddenly release and cause serious injury.

5. Always follow the manufacturer's instructions for your specific spring compressor tool.

6. If you feel uncomfortable or unsure about any part of the process, seek assistance from a qualified mechanic.

Here are a few additional tips to make your spring compression experience smoother and safer:

1. Use a torque wrench to ensure all fasteners are tightened to the correct specifications.

2. Inspect the spring for any signs of damage before using it. If there are any cracks or breaks, replace the spring immediately.

3. Use a lubricant to help ease the spring compression and decompression process.

4. Be patient and take your time. Rushing can lead to mistakes and safety hazards.

Spring coil compressor tools are essential equipment for anyone involved in spring-related repairs, especially those working with automotive suspension systems. They provide a safe and efficient method for compressing and decompressing springs, minimizing the risk of injuries and accidents. By understanding the different types of tools, selecting the right one for your needs, and following proper safety procedures, you can ensure a smooth and safe spring compression process.

Remember, safety should always be your top priority. By carefully following the guidelines in this article, you can use a spring coil compressor tool confidently and efficiently, ensuring a successful spring-related repair. If you're ever unsure about a particular step or have any questions, don't hesitate to seek help from a qualified professional.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.