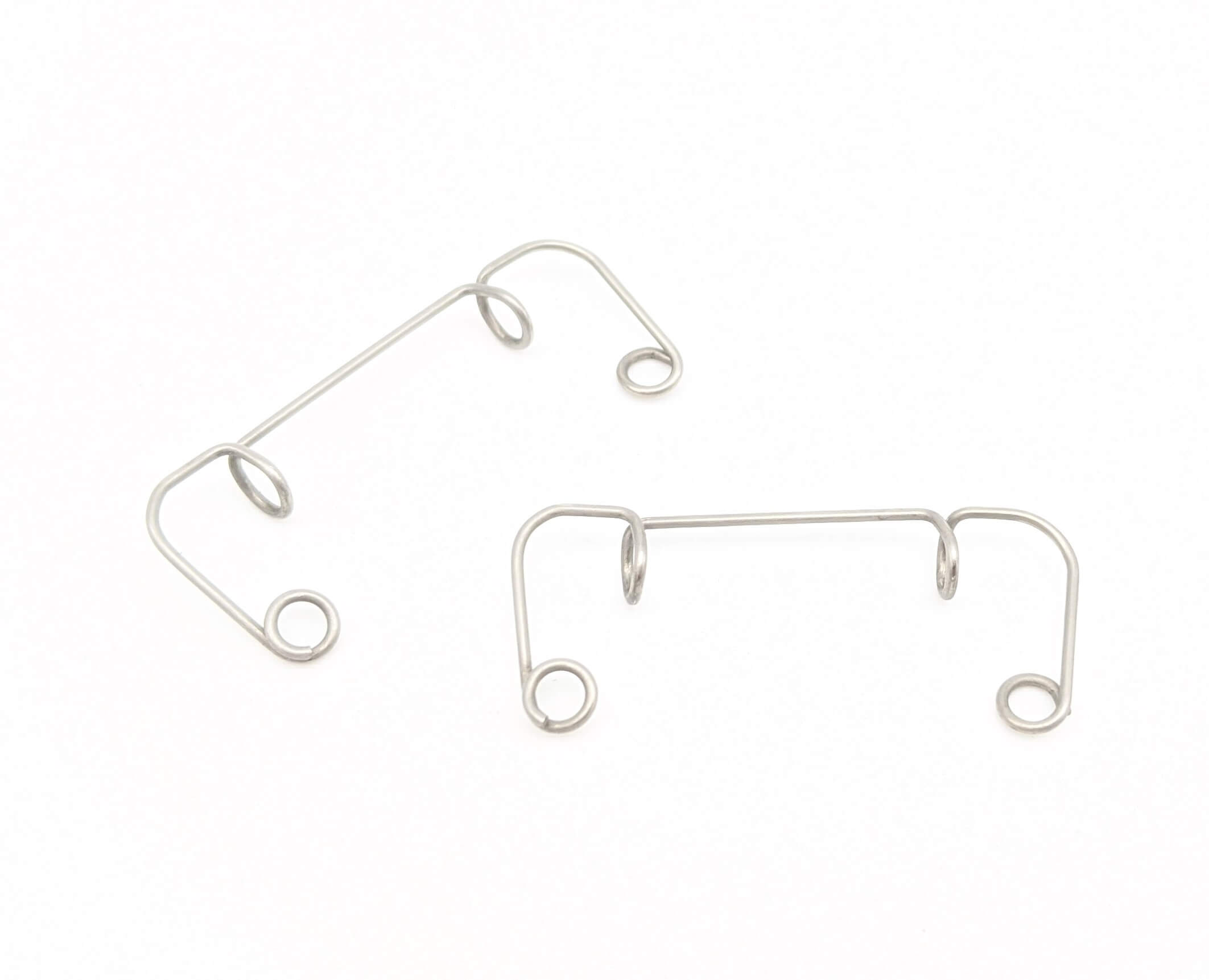

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Split wave spring washers, often called Belleville washers, are deceptively simple yet incredibly versatile components. These disk-shaped springs pack a punch in terms of force and are remarkably adaptable to

Split wave spring washers, often called Belleville washers, are deceptively simple yet incredibly versatile components. These disk-shaped springs pack a punch in terms of force and are remarkably adaptable to a variety of applications. Their unique design allows them to handle heavy loads, absorb shock, and provide precise tensioning. This article dives deep into the world of split wave spring washers, exploring their construction, characteristics, benefits, and applications in various industries.

At their core, split wave spring washers are conical or dish-shaped components made from spring steel. The distinctive shape and material allow them to store and release energy efficiently, providing a spring-like action. They are known for their ability to generate high clamping forces with minimal deflection, a crucial factor in many engineering applications.

The unique geometry of split wave spring washers is what makes them so effective. Their curved, wave-like design allows them to efficiently absorb and release energy when subjected to compression or tension. This spring action provides a variety of benefits, including:

The versatility of split wave spring washers has led to their widespread use in a multitude of industries. Here are some key application areas:

Selecting the appropriate split wave spring washer for your application depends on several factors, including:

Carefully considering these factors and consulting technical specifications will ensure you choose the right washer for your specific needs.

Like any component, split wave spring washers have both advantages and disadvantages. Understanding these aspects is essential for informed selection and application.

Split wave spring washers, while seemingly simple, are complex and powerful components that play crucial roles in a wide range of industries. Their ability to handle high loads, absorb shock, and provide precise tensioning makes them essential in applications demanding reliability, safety, and durability. By understanding their construction, characteristics, and applications, engineers can effectively leverage the benefits of split wave spring washers in their designs, optimizing performance and extending the lifespan of critical systems.

In conclusion, split wave spring washers, with their unique design and remarkable properties, are integral components in a variety of engineering solutions. By providing high clamping forces, absorbing shock loads, and enabling precise tensioning, they contribute significantly to the reliability, safety, and performance of various systems. Their versatility and adaptability across diverse industries have made them indispensable in modern engineering, and their role in ensuring optimal function and longevity continues to evolve with technological advancements.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.