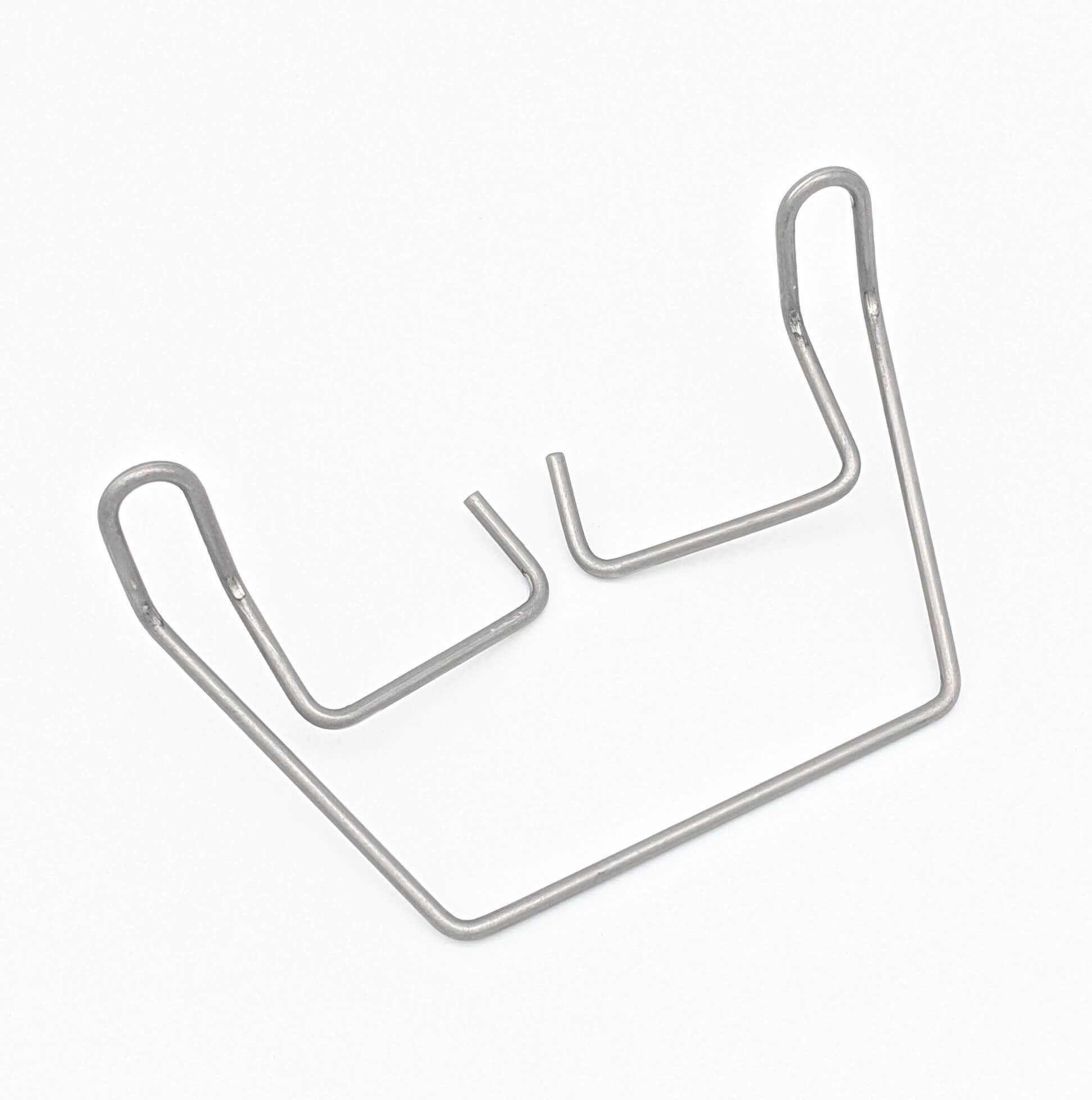

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Split wave disc springs, also known as Belleville washers, are a unique and versatile type of spring that offers several advantages over traditional coil springs. Their distinctive design, consisting of

Split wave disc springs, also known as Belleville washers, are a unique and versatile type of spring that offers several advantages over traditional coil springs. Their distinctive design, consisting of a conical disc with a split or wave pattern, allows them to achieve high force levels within a compact footprint. These springs are widely used in various industries for applications ranging from clamping and preloading to shock absorption and energy storage. This article will delve into the intricacies of split wave disc springs, exploring their working principle, design characteristics, advantages, and applications.

Split wave disc springs are characterized by their distinct conical shape and the split or wave pattern along their circumference. This distinctive design significantly influences their spring characteristics. The wave pattern introduces a unique load-deflection curve, leading to a non-linear spring rate. In essence, the spring stiffens as the load increases, providing higher force at higher deflection.

Split wave disc springs offer several advantages over conventional coil springs, making them a preferred choice for many applications:

Split wave disc springs come in various configurations, each offering distinct spring characteristics and performance. Common types include:

Split wave disc springs find wide applications across various industries, due to their unique characteristics. Some common applications include:

Designing with split wave disc springs requires careful consideration of factors like load requirements, space constraints, and desired spring rate. Experienced engineers and designers can utilize specialized software and industry standards to optimize the design of these springs for specific applications.

When selecting split wave disc springs, several critical factors should be considered:

Split wave disc springs are a highly versatile and powerful type of spring that offers significant advantages over traditional coil springs. Their unique design, combined with their high force capacity, compact size, and variable spring rate, make them ideal for a wide range of applications. By understanding the key considerations for design and selection, engineers and designers can effectively leverage the benefits of split wave disc springs in their projects, achieving superior performance and reliability.

This article has provided a comprehensive overview of split wave disc springs, covering their design, advantages, applications, and key selection factors. By carefully considering these factors and working with experienced engineers, designers can effectively utilize split wave disc springs to enhance the functionality and reliability of their projects, ultimately leading to improved performance and longevity.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.