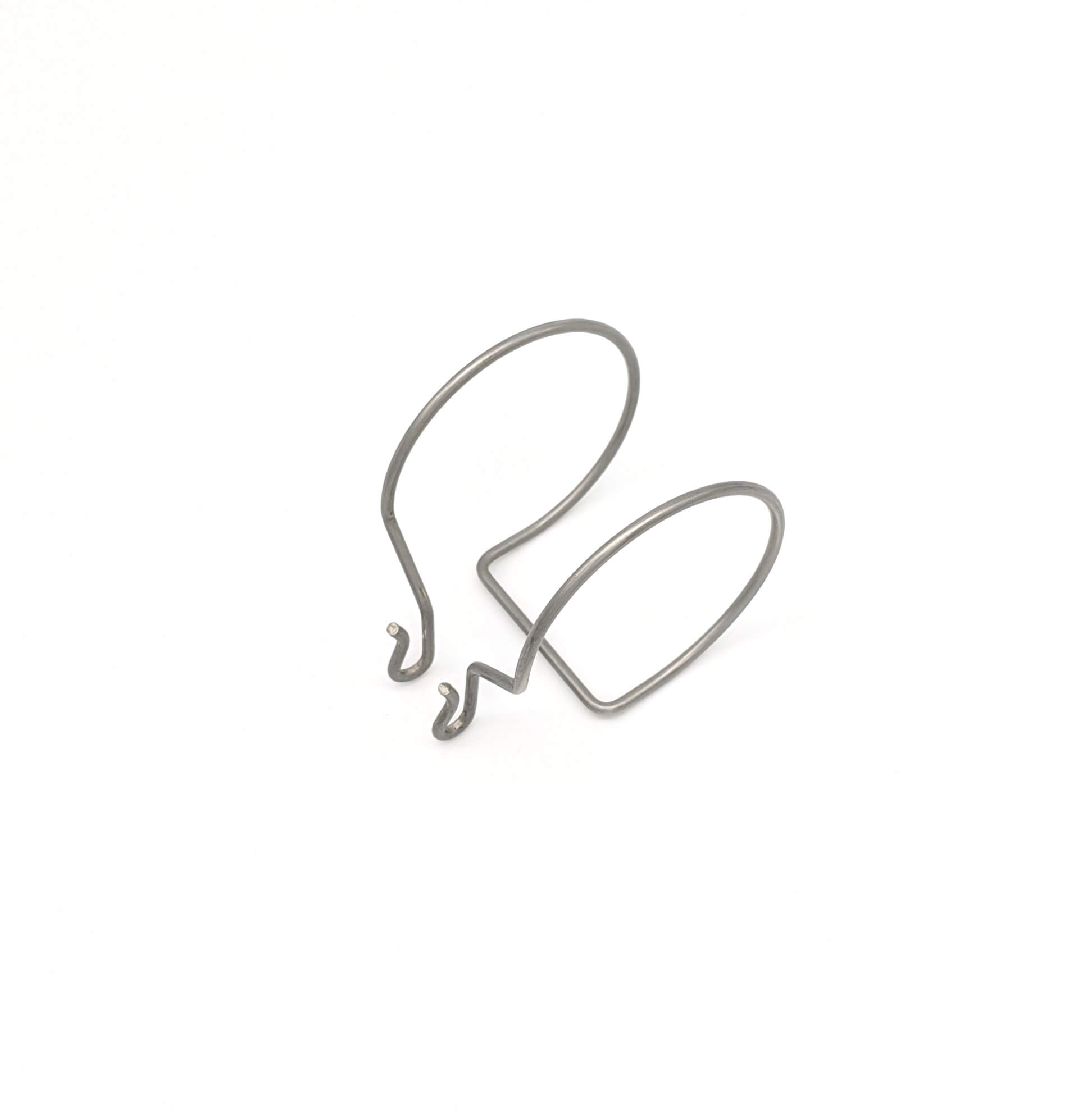

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of engineering, where precision and performance reign supreme, seemingly insignificant components can play pivotal roles. One such component, often overlooked yet indispensable, is the smally wav spring.

In the world of engineering, where precision and performance reign supreme, seemingly insignificant components can play pivotal roles. One such component, often overlooked yet indispensable, is the smally wav spring. These miniature marvels, despite their diminutive size, pack a punch when it comes to providing reliable and efficient mechanical support. This article delves into the fascinating realm of smally wav springs, exploring their unique characteristics, applications, and the impact they have on various industries.

Imagine a spring, but one that's so small it's almost invisible to the naked eye. That's the essence of a smally wav spring. These springs, typically measuring less than a millimeter in diameter, are crafted with meticulous precision to deliver exceptional performance in compact spaces. Their unique wave-like design, achieved through specialized manufacturing processes, bestows upon them remarkable strength and resilience.

The 'wav' in their name isn't just a stylistic choice; it reflects the spring's distinctive wavy configuration. This design, with its alternating crests and troughs, allows smally wav springs to absorb significant energy, making them perfect for applications where space is at a premium and shock absorption is critical. Think of them as tiny shock absorbers, quietly working behind the scenes to protect delicate components from damage.

Their diminutive size belies the sheer versatility of smally wav springs. These miniature powerhouses find their way into a vast array of industries, contributing significantly to the smooth operation of countless mechanical systems. From the intricate workings of medical devices to the robust construction of automobiles, smally wav springs are indispensable.

In the medical field, smally wav springs play a crucial role in ensuring the accuracy and reliability of delicate instruments. For instance, in surgical tools, these springs can provide the necessary force to hold components in place, enabling surgeons to perform intricate procedures with precision. Their biocompatibility makes them suitable for use in prosthetics, ensuring smooth and natural movement for patients.

The automotive industry relies heavily on smally wav springs to enhance performance and safety. These tiny springs find their way into components like fuel injectors, where they provide precise control over fuel delivery, optimizing engine efficiency. In safety features, such as seatbelt mechanisms, smally wav springs ensure the smooth and reliable operation of these critical components, safeguarding passengers in the event of an accident.

The allure of smally wav springs lies in their remarkable combination of size, strength, and resilience. Their small footprint is a major advantage in applications where space is limited, such as in electronic devices, where they can be used to provide spring pressure for connectors and switches.

Moreover, their inherent strength and ability to withstand fatigue make them ideal for high-cycle applications. They can be repeatedly compressed and extended without losing their shape, ensuring consistent performance over time. This quality is particularly valuable in applications where reliability is paramount, like in aerospace components where failure is not an option.

The creation of these tiny wonders is a testament to the precision and ingenuity of modern manufacturing techniques. Specialized machinery is employed to form the intricate wave pattern in the spring wire, ensuring that the finished product meets the stringent quality standards demanded by the industry.

The materials used in smally wav spring production are carefully chosen based on the specific application. Stainless steel, for its corrosion resistance and strength, is a common choice, while other materials, like nickel alloys, are utilized when specific performance characteristics are required. The manufacturing process, from wire selection to final heat treatment, is meticulously controlled to ensure the consistency and quality of the finished product.

As technology continues to advance, the demand for miniaturization and high performance will only intensify. Smally wav springs are poised to play an even more prominent role in shaping the future of mechanical systems.

With advancements in materials science, we can expect to see the development of even smaller, more resilient smally wav springs. The integration of these springs into smart devices, sensors, and microfluidics will push the boundaries of what's possible in fields like robotics, healthcare, and environmental monitoring.

The future of smally wav springs holds tremendous promise. Their ability to deliver exceptional performance in compact spaces makes them essential building blocks for the next generation of innovative technologies. As engineers continue to explore the limits of miniaturization, these tiny powerhouses will undoubtedly play a pivotal role in shaping the world around us.

In conclusion, smally wav springs are not just small components; they are integral to the seamless operation of countless mechanical systems. Their versatility, strength, and resilience make them indispensable across a wide range of industries. As technology evolves, the demand for these miniature marvels is only expected to grow, solidifying their position as essential building blocks for the future of innovation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.