Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

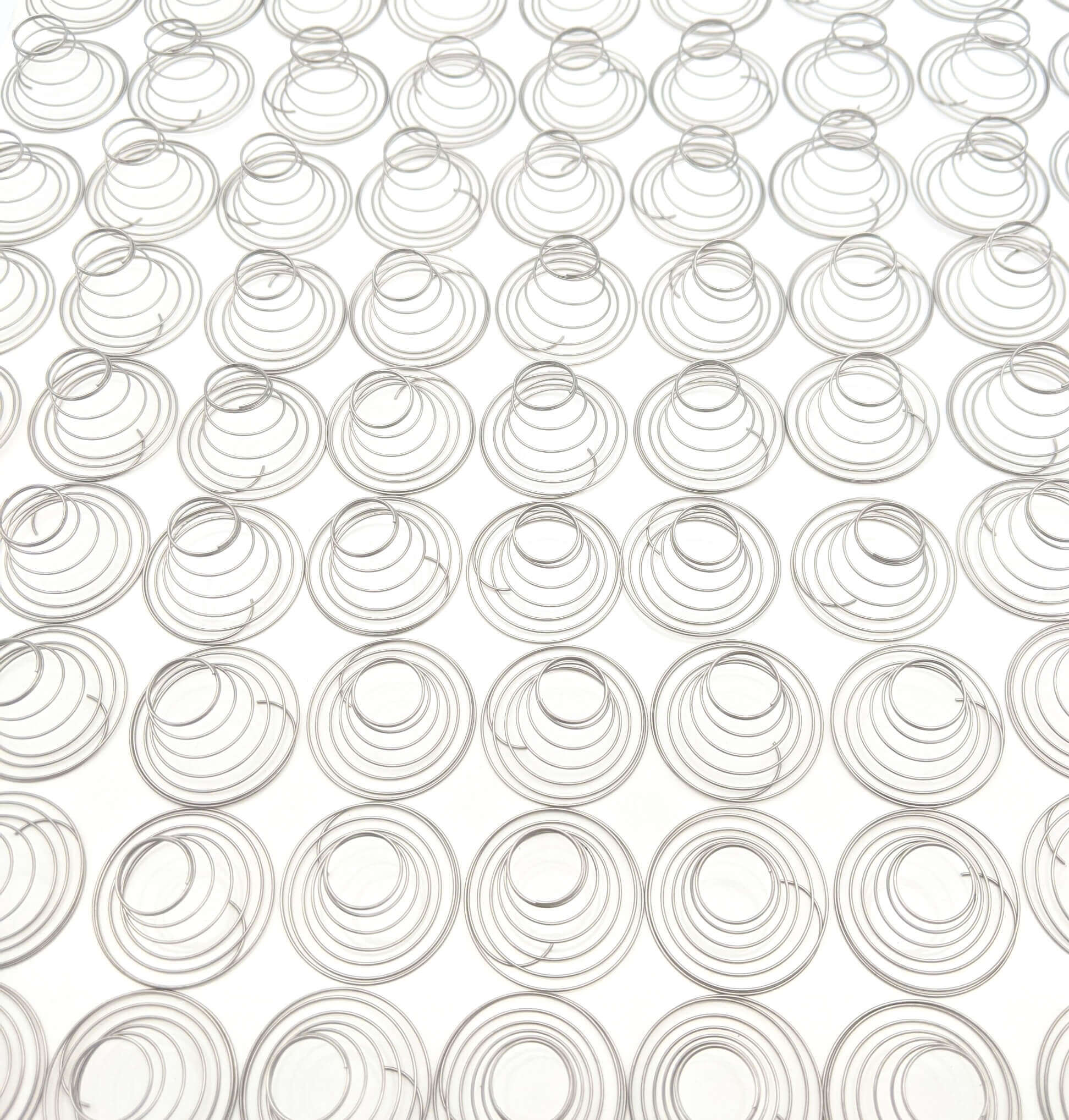

Small wave springs, often called wave washers, are a fascinating type of spring that packs incredible strength and resilience into a compact form. Unlike traditional coil springs, wave springs use

Small wave springs, often called wave washers, are a fascinating type of spring that packs incredible strength and resilience into a compact form. Unlike traditional coil springs, wave springs use a series of curved waves to create their spring action. This unique design offers several advantages, including a high spring rate, durability, and exceptional resistance to fatigue. Whether you're working on a miniature device, a delicate medical instrument, or a high-performance engine, small wave springs can be a game-changer, offering solutions that might seem impossible with other spring designs.

Imagine a spring that's incredibly strong yet amazingly compact. That's the magic of small wave springs. Their construction, a series of curved waves rather than a continuous coil, allows them to generate a high spring rate in a small footprint. This makes them ideal for applications where space is limited, such as in microelectronics, medical devices, and even aerospace components.

The advantages of using small wave springs extend beyond their size. They are remarkably durable, able to withstand thousands of cycles without showing significant signs of wear or fatigue. This resilience is crucial in applications where reliability is paramount, such as in automotive suspension systems or precision instruments.

The secret to the strength of small wave springs lies in their unique design. Each wave is carefully engineered to create a specific amount of deflection when compressed. The spring rate, which measures how much force is required to compress the spring by a specific distance, is directly related to the shape and arrangement of these waves. By manipulating the design, engineers can tailor the spring rate to meet the exact needs of a particular application.

The applications of small wave springs are truly diverse, spanning industries as varied as medicine, aerospace, and automotive. Here are just a few examples:

Selecting the right small wave spring requires careful consideration of the specific application. Factors such as the spring rate, material, and dimensions all play a role in ensuring optimal performance. Working with an experienced spring manufacturer is crucial to ensure that you choose a spring that meets your exact needs.

The innovative design of small wave springs continues to evolve, with new materials and manufacturing techniques constantly pushing the boundaries of what's possible. As technologies advance, we can expect to see even more innovative applications for these versatile and powerful springs.

Small wave springs are a testament to the ingenuity of engineers who constantly strive to create compact and reliable solutions for a wide range of applications. Whether you're a designer working on a high-precision medical device or a manufacturer developing a cutting-edge automotive component, small wave springs offer a unique combination of strength, resilience, and compactness. As we continue to push the boundaries of technology, small wave springs are sure to play an increasingly important role in shaping the future.

In conclusion, small wave springs are a valuable tool for engineers and designers looking for compact and durable solutions. Their unique design offers a high spring rate and exceptional resistance to fatigue, making them suitable for a vast array of applications. As technology continues to evolve, we can expect to see even more innovative applications for small wave springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.