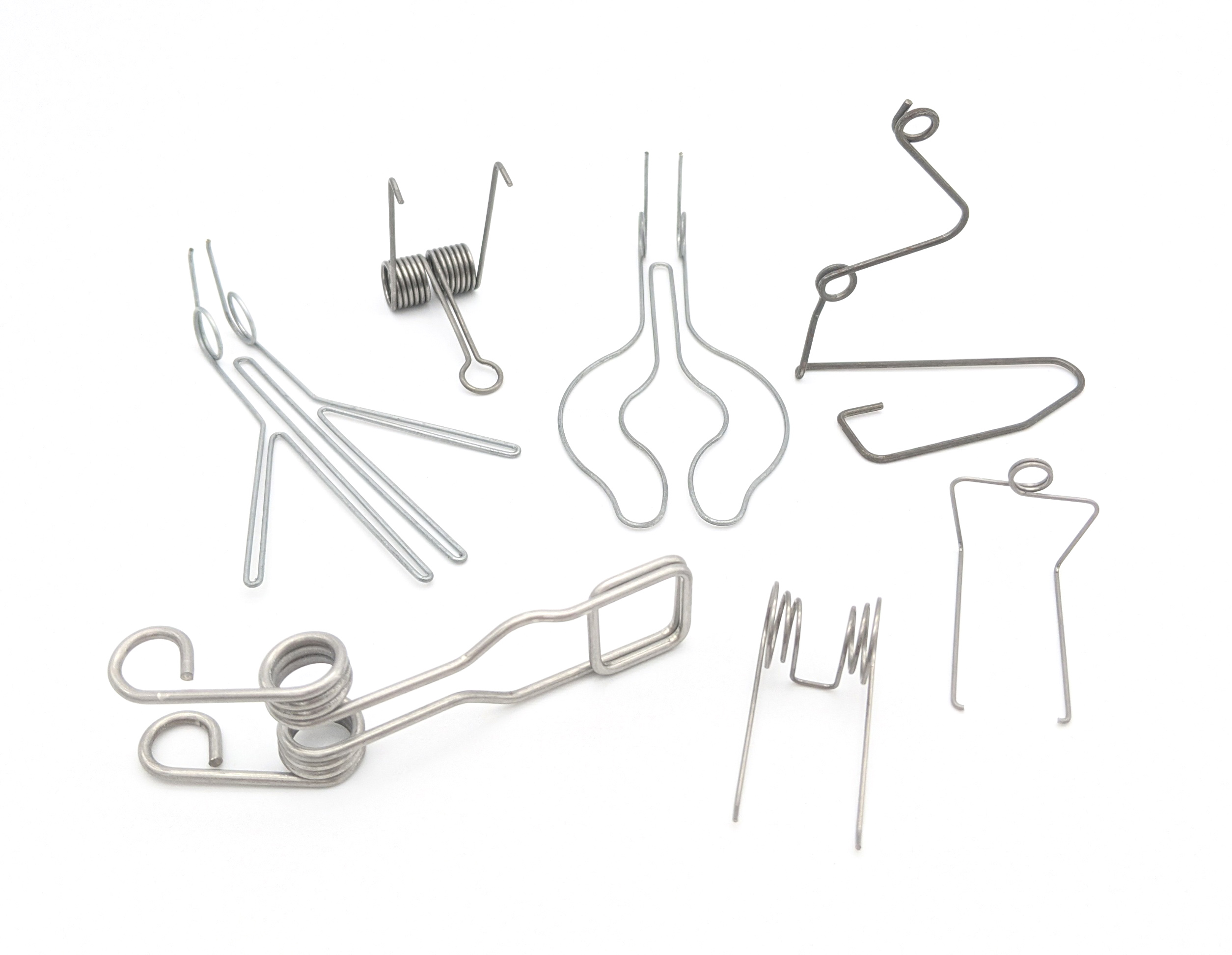

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a spring so small, so delicate, that it can fit in the palm of your hand. Yet, this tiny marvel can pack a powerful punch, capable of delivering precise

Imagine a spring so small, so delicate, that it can fit in the palm of your hand. Yet, this tiny marvel can pack a powerful punch, capable of delivering precise forces and movements in a variety of applications. This is the world of small wave springs, a fascinating realm where engineering meets ingenuity to create miniature solutions for complex challenges.

Small wave springs, sometimes called wave springs or Belleville washers, are a unique type of spring design. Unlike traditional coil springs, wave springs are made from a single piece of flat, spring steel that is precisely shaped into a series of waves. These waves, when compressed, generate a significant force, making these springs ideal for applications where space is limited, but high force is required.

These springs are often found in small, intricate mechanisms, where their compact size and high force output make them invaluable. You might be surprised to learn how many everyday items rely on small wave springs. They power everything from the tiny mechanisms in your phone or watch to the crucial components in medical devices and aerospace equipment.

What makes small wave springs so special? Their unique design offers several advantages over traditional coil springs:

The applications of small wave springs are as diverse as their advantages. Here are just a few examples:

With such a wide range of applications, it's important to choose the right small wave spring for your specific needs. Factors to consider include:

By carefully considering these factors, you can select the perfect small wave spring for your application.

As technology continues to advance, the role of small wave springs will only become more significant. Their compact size, high force output, and precision make them ideal for a wide range of applications in the fields of robotics, nanotechnology, and other emerging technologies. As we push the boundaries of innovation, small wave springs will continue to play a vital role in shaping the future of engineering and design.

Small wave springs are a testament to the power of ingenuity and precision engineering. These tiny, yet powerful, springs are changing the way we think about design and function, opening up a world of possibilities for innovation and progress. So the next time you encounter a miniature mechanism or a device that seems to defy its size, take a moment to appreciate the small wave spring that might be at work behind the scenes.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.