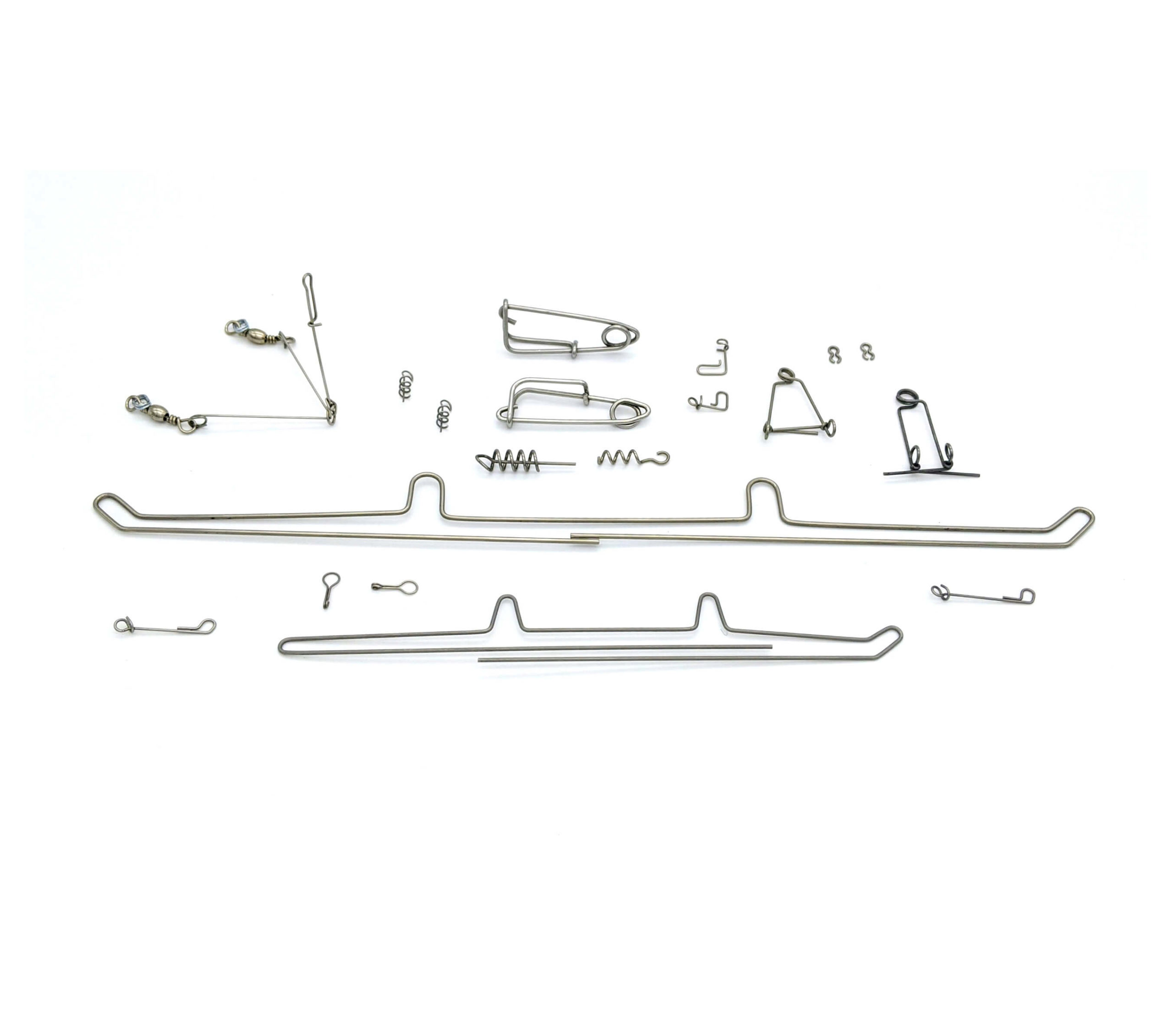

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small wave springs, often overlooked in the realm of mechanical engineering, are a fascinating and versatile component with a surprising range of applications. Their unique design, characterized by a series

Small wave springs, often overlooked in the realm of mechanical engineering, are a fascinating and versatile component with a surprising range of applications. Their unique design, characterized by a series of precisely formed waves, allows them to provide reliable and consistent spring force in compact configurations. This article delves into the world of small wave springs, exploring their design, advantages, and diverse applications that extend far beyond traditional spring applications.

Small wave springs are a type of compression spring that are characterized by their unique wave-like design. Unlike traditional helical springs that rely on a coil shape for their functionality, wave springs use a series of precisely formed waves to create a compact and efficient spring mechanism. The waves are created by bending a flat strip of material into a series of alternating curves, which gives the spring its distinctive appearance.

This unique design offers several advantages over traditional helical springs:

1. Compact Size: Wave springs are significantly more compact than helical springs with the same spring rate, making them ideal for applications where space is limited. This makes them especially valuable in miniature devices and precision assemblies.

2. High Load Capacity: Due to their design, wave springs can handle heavier loads than traditional helical springs of the same size. They are able to achieve higher spring rates without increasing the overall size of the spring, which is particularly beneficial in high-stress applications.

3. Durability and Long Life: Wave springs are made from durable materials like spring steel, making them resilient to wear and tear. The material properties and the compact design contribute to a long service life, reducing the need for frequent replacements.

4. Consistent Performance: Wave springs offer a high degree of precision and consistency in their spring rate. The uniformity of the waves ensures that the force applied by the spring is predictable and reliable over a wide range of compression levels, making them suitable for applications demanding accuracy.

The versatility of small wave springs has made them indispensable in a wide range of industries and applications. Their compact size, high load capacity, and consistent performance make them suitable for both miniature and large-scale projects.

1. Electronics: Small wave springs are a common sight in electronic devices, providing spring pressure for connectors, switches, and other components. Their compact size and high spring rate allow them to perform reliably in delicate circuitry without taking up excessive space.

2. Medical Devices: The biocompatibility of certain materials used in wave springs makes them ideal for use in medical devices. They can be found in syringes, surgical instruments, and other medical equipment, where precision and reliability are paramount.

3. Aerospace: Wave springs are employed in aerospace applications due to their ability to withstand high loads and operate in extreme environments. They can be found in aircraft components, spacecraft systems, and other high-performance equipment.

4. Automotive: Small wave springs play a crucial role in various automotive components, including brakes, clutches, and suspension systems. Their compact size and high load capacity allow them to operate efficiently in confined spaces while providing the necessary spring force for these critical systems.

5. Consumer Products: Small wave springs are used in a wide range of consumer products, from pens and toys to appliances and furniture. They offer a cost-effective solution for providing spring action in a variety of everyday items.

The benefits of small wave springs, including their compact size, high load capacity, durability, and consistent performance, have made them a valuable component in various industries. Their versatility has opened up numerous applications across diverse sectors, from miniature electronics to large-scale machinery. As technology continues to advance and the need for miniaturization increases, small wave springs are poised to play an even greater role in the future of engineering.

Small wave springs are a testament to the ingenuity of engineering and their potential is far from being fully realized. Their compact design, exceptional strength, and adaptability make them an ideal choice for a vast range of applications. As technology continues to advance, we can expect to see even more innovative uses for these versatile springs in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.